The Benefits Of Proper Sanitation Before Production In Fisheries Industries

By. Fajar - 03 Sep 2025.jpg)

Kelolalaut.com In the seafood industry, ensuring food safety and quality is more than just a regulatory requirement—it is a responsibility to consumers and a key driver of business success. Among the many practices that fisheries businesses must follow, proper sanitation of equipment before production stands out as one of the most critical. Clean tools, machinery, and work surfaces not only safeguard public health but also improve efficiency, enhance market opportunities, and strengthen brand reputation.

Below are four major benefits of proper sanitation before production that every fishery business should prioritize.

1. Protecting Consumer Health

The foremost benefit of proper sanitation is protecting consumers from foodborne illnesses. Seafood is highly perishable and prone to contamination if not handled under strict hygienic conditions. Harmful bacteria such as Listeria monocytogenes, Salmonella, and Vibrio can thrive in fish processing environments if equipment is not thoroughly cleaned and sanitized before use.

By removing microbial hazards and preventing cross-contamination, sanitation ensures that seafood reaching consumers is safe to eat. This protection is not only about preventing illness—it is also about maintaining consumer trust. When buyers know that a business prioritizes hygiene, they are more confident in purchasing seafood products. A single food safety incident can damage a company’s reputation for years, while consistent cleanliness builds loyalty and credibility.

2. Preserving Product Quality

Sanitation directly impacts the quality and shelf life of seafood. Contaminated equipment can accelerate spoilage, leading to changes in taste, texture, smell, and appearance. On the other hand, when equipment is properly sanitized, seafood maintains its natural freshness for longer.

For businesses, this means that products stay appealing during storage, transport, and display in retail markets. For consumers, it ensures that seafood not only looks and tastes better but also retains its nutritional value. Longer shelf life is particularly important for exported seafood products, which must endure long shipping times without losing quality. By preventing microbial growth at the earliest stages, sanitation plays a vital role in preserving the value of seafood from production to the final point of sale.

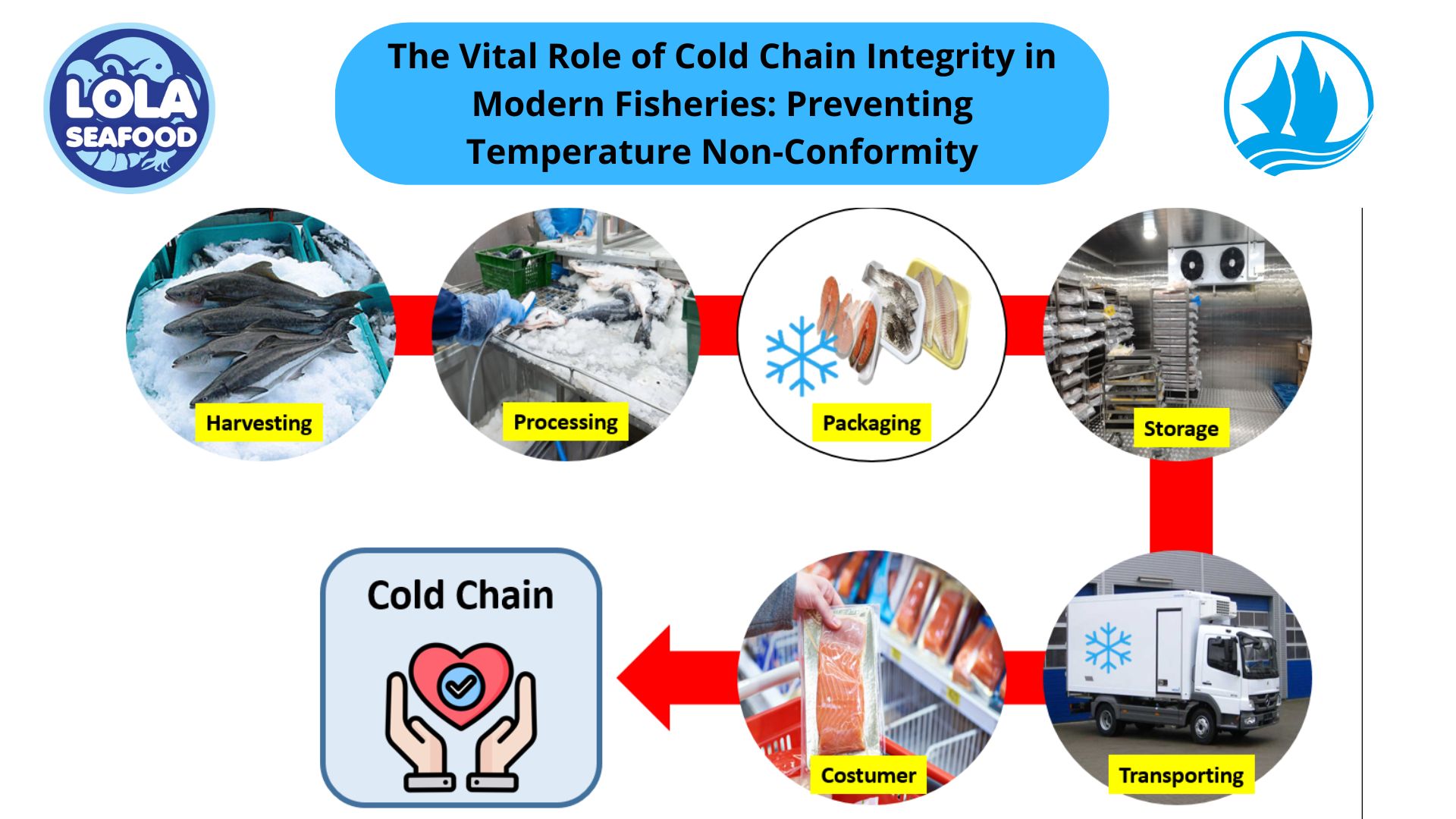

3. Supporting Compliance and Market Access

In today’s interconnected food system, sanitation is also a passport to international trade. Many global markets, including the European Union, the United States, and Japan, have strict requirements for food safety. Businesses exporting seafood must demonstrate compliance with standards such as Good Manufacturing Practices (GMP) and Hazard Analysis and Critical Control Points (HACCP).

Proper sanitation before production is a core component of these systems. Documented cleaning schedules, sanitation records, and verification procedures are often reviewed by auditors and regulators. Without them, businesses risk losing access to lucrative export opportunities.

By consistently implementing sanitation protocols, fisheries businesses not only comply with domestic laws but also strengthen their competitiveness in global markets. In other words, sanitation is not just about cleanliness—it is about building credibility and opening doors to international trade.

4. Reducing Waste and Operational Costs

Spoiled or contaminated seafood cannot be sold, leading to significant financial losses. In some cases, entire shipments are rejected, recalled, or destroyed due to poor sanitation practices. Beyond the immediate loss of product, such incidents increase operational costs and damage a company’s reputation.

By maintaining clean equipment before production, fisheries businesses can minimize waste and improve efficiency. Preventing contamination at the source means fewer product recalls, lower rejection rates, and reduced disposal costs. Moreover, efficient sanitation routines also support smoother operations by ensuring equipment is in good working condition and ready for production. In the long run, investing in proper sanitation is more cost-effective than dealing with the consequences of unsafe or spoiled products.

Proper sanitation before production in fishery factories is not just a routine task—it is a foundation for food safety, product quality, and business success. Clean equipment protects consumer health, preserves the freshness and appeal of seafood, supports compliance with international standards, and reduces waste and costs. For fisheries businesses aiming to thrive in today’s competitive market, sanitation is both a responsibility and a strategic advantage. By prioritizing hygiene, companies not only protect their customers but also secure long-term growth, credibility, and sustainability in the global seafood industry.

If you are intrested in our Goldband / Crimson Snapper Whole Round, Goldband / Crimson Snapper Fillet Skin On , White Snapper / Robinson Seabream / Seabream Whole Round / Whole Gilled Gutted Scaled , White Snapper / Robinson Seabream / Seabream Fillet Skin On , Snapper Whole Round / Whole Gilled Gutted Scaled , Red / Scarlet Snapper Fillet Portion, Red / Scarlet Snapper Fillet Skin On , Snapper Fillet Skinless please do not hesitate to contact us to email and / or whatsapp

The Dominance of Demersal Fish: The Strategic Export Potential of Indonesia’s Grouper and Parrotfish

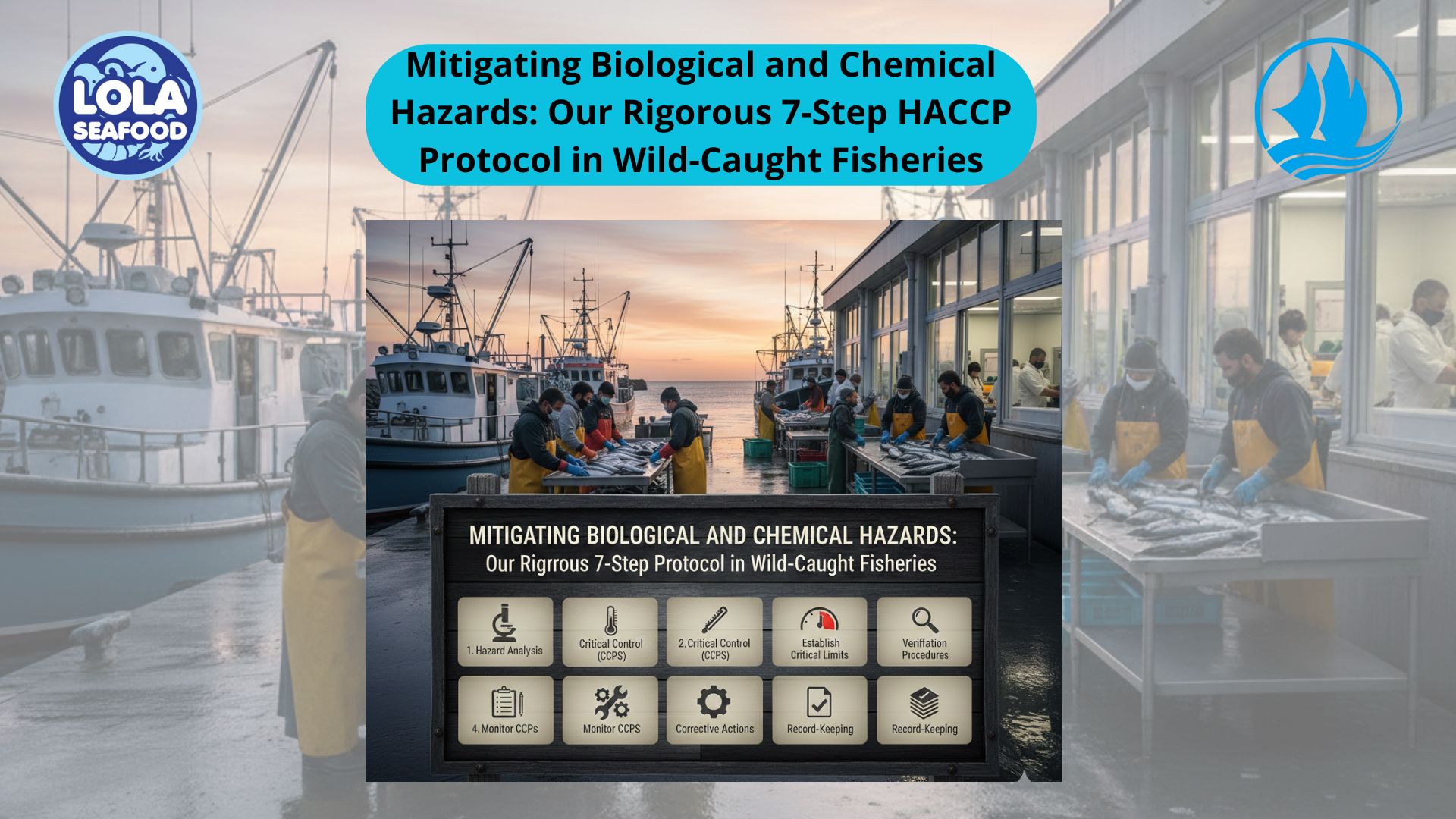

Mitigating Biological and Chemical Hazards: Our Rigorous 7-Step HACCP Protocol in Wild-Caught Fisheries

.jpg)