Ensuring Pure Catch: Strategies for Eliminating Bacterial Contamination in Seafood

By. Ely Kusniawati - 26 Dec 2025

kelolalaut.com The global seafood industry is a cornerstone of nutrition and commerce, providing high-quality protein to billions. However, because seafood is highly perishable and often harvested from dynamic aquatic environments, it is uniquely susceptible to bacterial contamination. From the moment a fish is pulled from the water to the second it reaches the consumer’s plate, a "cold chain" and "clean chain" must be maintained. Eliminating bacterial sources is not just a matter of quality—it is a critical public health necessity.

The Nature of the Threat

Seafood contamination generally stems from two sources: indigenous bacteria, which naturally exist in the ocean (such as Vibrio species), and non-indigenous bacteria, which are introduced through human handling, contaminated water, or pests (such as Salmonella, E. coli, and Listeria).

To effectively eliminate these threats, we must address the three primary stages of the seafood supply chain: the environment, the vessel, and the processing facility.

1. Control at the Source: Harvesting and Water Quality

The elimination of contamination begins before the fish is even caught. For bivalve mollusks like oysters and clams, water quality is the deciding factor. Since these organisms are filter feeders, they concentrate bacteria from the surrounding water.

- Zonal Monitoring: Authorities must strictly monitor harvesting zones for runoff and sewage discharge, especially after heavy rains which can spike E. coli levels.

- Depuration: For high-risk shellfish, using depuration tanks—where clean, UV-treated seawater is circulated—allows the animals to naturally purge contaminants from their systems.

2. Hygiene on the Vessel: The First Line of Defense

The fishing vessel itself is often the first point of man-made contamination. If the deck, nets, or storage bins are not sanitized, bacteria from previous catches can "seed" the new harvest.

- Sanitization Protocols: Decks and contact surfaces should be cleaned with food-grade detergents and sanitized using chlorine-based solutions or peracetic acid.

- Personal Hygiene: Crew members must be trained in rigorous hand-washing. Since many pathogens are transferred via human touch, the use of gloves and dedicated waterproof clothing is essential.

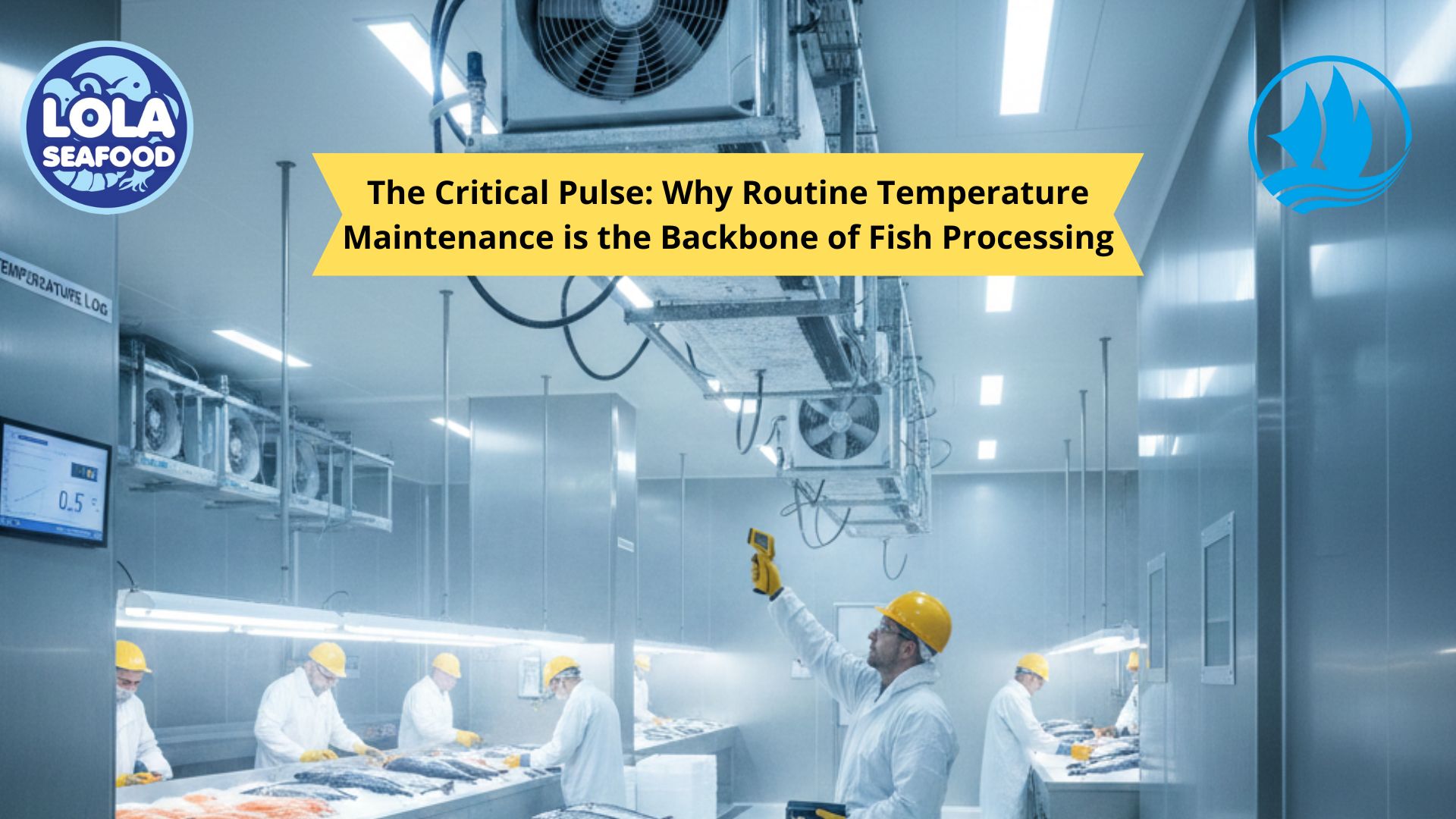

3. The Power of Temperature: The Rule of 4°C

Bacteria thrive in the "Danger Zone" between 5°C and 60°C. In this range, populations can double every 20 minutes.

- Rapid Chilling: Immediately after harvest, the internal temperature of the catch must be brought down to near 0°C. This is best achieved using Slurry Ice (a mixture of ice and seawater). Slurry ice provides faster cooling than flake ice because it completely surrounds the fish, eliminating air pockets where bacteria might grow.

- Maintaining the Cold Chain: Every transfer point—from the boat to the truck to the warehouse—must be temperature-controlled. A single hour of temperature abuse can significantly shorten shelf life and increase the risk of Scombrotoxin (histamine) formation in species like tuna and mackerel.

4. Eliminating Cross-Contamination in Processing

Once the catch reaches the processing plant, the complexity of contamination risks increases. Cross-contamination occurs when bacteria move from a "dirty" area (like the receiving dock) to a "clean" area (the packaging line).

- HACCP Implementation: The Hazard Analysis and Critical Control Point (HACCP) system is the gold standard. It identifies specific points where contamination could occur and sets strict limits to prevent it.

- Aseptic Design: Modern facilities use stainless steel equipment with smooth welds. Pitted surfaces or "dead ends" in machinery can harbor biofilms—resilient colonies of bacteria like Listeria that are extremely difficult to kill with standard cleaning.

5. Advanced Intervention Technologies

As science evolves, new methods are being used to eliminate bacteria without damaging the delicate texture of the seafood.

- High-Pressure Processing (HPP): Subjecting seafood to intense pressure can kill pathogens like Vibrio while keeping the product raw and fresh.

- Ozonated Water: Using ozone (O3) in wash water is a powerful, residue-free way to kill surface bacteria. Ozone is more effective than chlorine and reverts back to oxygen, leaving no chemical trace.