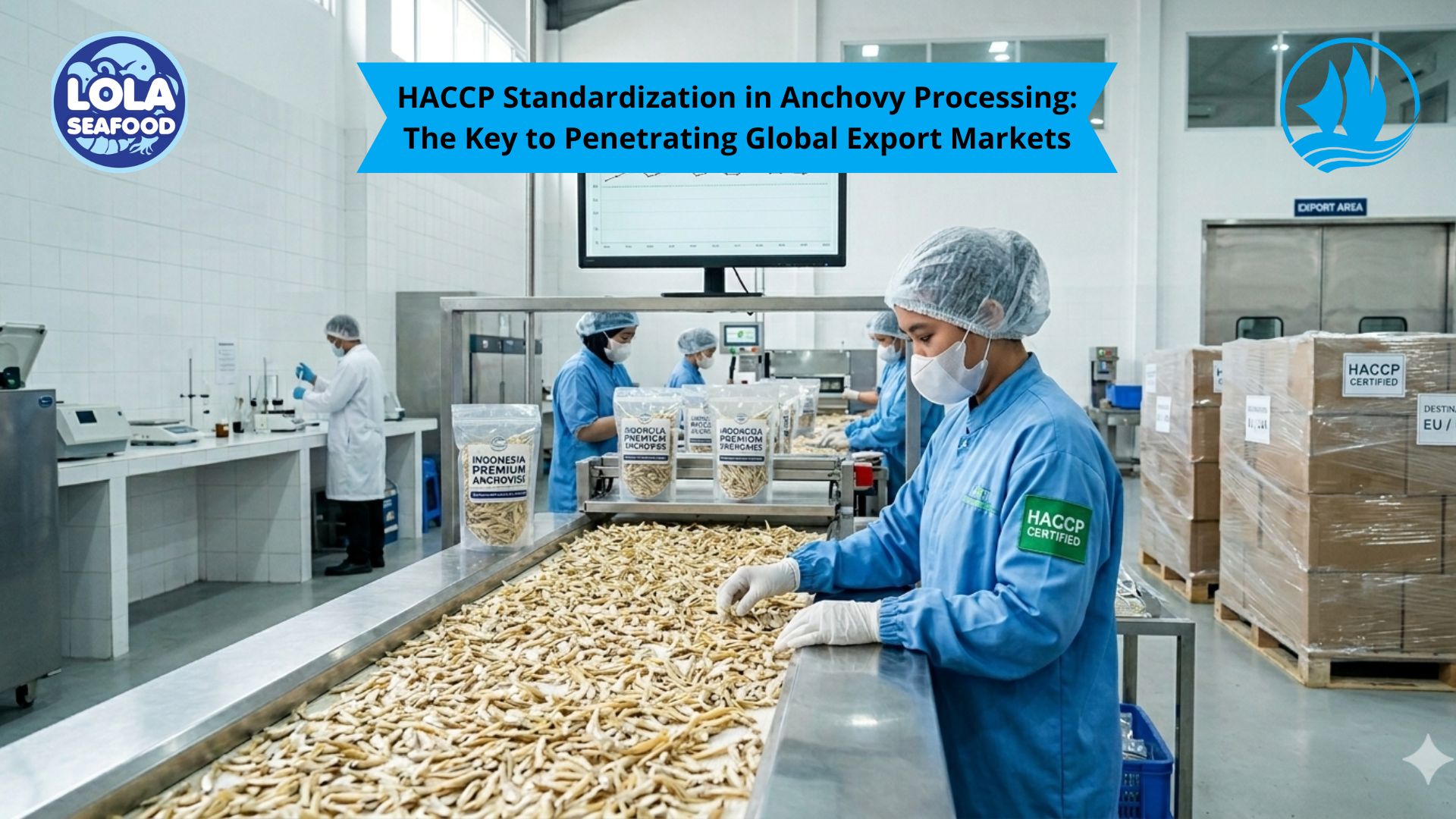

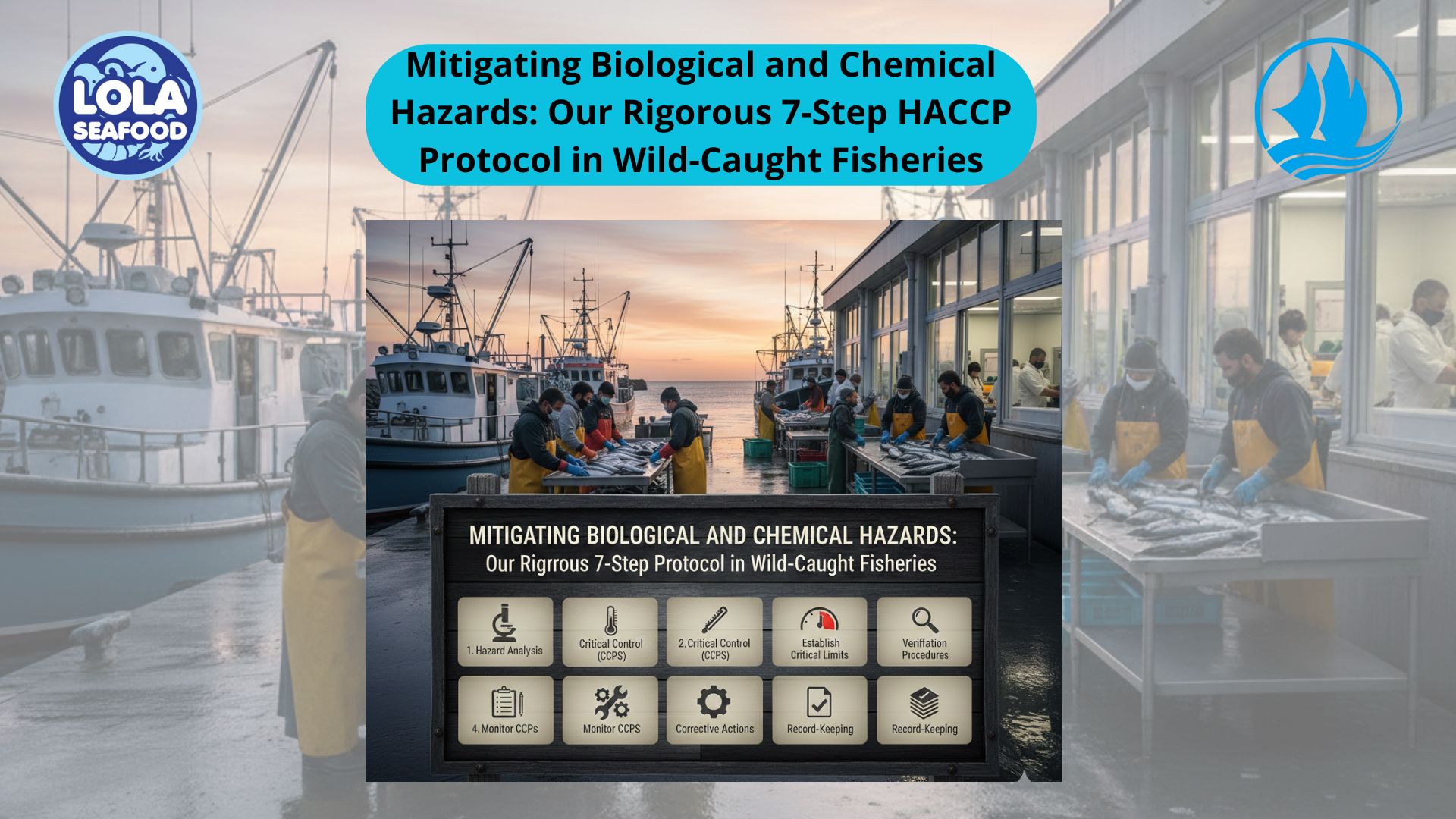

Mitigating Biological and Chemical Hazards: Our Rigorous 7-Step HACCP Protocol in Wild-Caught Fisheries

By. Puji Widyastuti - 06 Jan 2026

kelolalaut.com In the global seafood trade, wild-caught fisheries face a unique set of safety challenges. Unlike land-based food production, the "factory floor" is a fishing vessel in the middle of the ocean. The environment is corrosive, the raw material is highly perishable, and the distance from the shore makes monitoring difficult. To bridge this gap, our organization implements a rigorous 7-Step HACCP (Hazard Analysis and Critical Control Points) Protocol. This system ensures that biological and chemical hazards are mitigated at the source, long before the catch reaches the landing site.

Identifying the Invisible Threats at Sea

In wild-caught operations, we categorize hazards into two primary groups:

- Biological Hazards: The most significant threat is Scombrotoxin (Histamine) formation. In species like Tuna, Mackerel, and Mahi-mahi, improper cooling after death allows bacteria to convert histidine into histamine, which can cause severe allergic reactions in consumers. Other risks include Vibrio bacteria from seawater and parasites.

- Chemical Hazards: These often originate from the vessel itself. They include fuel oil, hydraulic fluids, and grease that can contaminate the catch if handling areas are not properly designed. Furthermore, environmental toxins like mercury or lead must be monitored based on the fishing grounds.

The 7-Step Protocol for Fisheries Excellence

1. Conduct a Comprehensive Hazard Analysis

Our protocol begins with a detailed analysis of the fishing operation. We ask: What species are we targeting? What is the sea surface temperature? How long is the duration of the haul? For wild-caught tuna, we identify that the struggle during capture raises the fish's internal body temperature, accelerating bacterial growth. This analysis allows us to tailor our safety measures to the specific risks of each voyage.

2. Determine Critical Control Points (CCPs)

A CCP is a stage where control is essential to prevent a safety hazard. In our fisheries model, the most vital CCP is On-Board Chilling (Initial Cooling). If the fish is not chilled immediately after harvest, the risk of histamine and spoilage becomes uncontrollable. Another CCP is the Selection of Fishing Grounds, where we avoid areas known for high levels of industrial chemical runoff.

3. Establish Critical Limits

Critical limits are the "safety boundaries" we must never cross. For wild-caught species, these are primarily time and temperature-based.

- Time Limit: Fish must be placed in Refrigerated Sea Water (RSW) or Slush Ice within 45 to 60 minutes of being landed on deck.

- Temperature Limit: The internal core temperature of the fish must be reduced to below 4.4°C (40°F) as quickly as possible and maintained near 0°C (32°F) throughout the voyage.

4. Establish Monitoring Procedures

Monitoring at sea requires disciplined record-keeping. Our crew uses calibrated digital thermometers to check the temperature of the brine tanks and the internal temperature of the largest fish in each haul. For chemical hazards, we monitor the integrity of the fuel lines and ensure that cleaning chemicals are stored in locked, separate compartments away from the fish-processing deck.

5. Establish Corrective Actions

When a critical limit is breached, immediate action is taken. If a refrigeration compressor fails and the brine temperature rises above the limit, the protocol dictates that the affected batch must be segregated. This "Suspect Product" is then subjected to lab testing for histamine upon landing. If it fails the safety test, it is destroyed or diverted for non-human consumption (such as fishmeal), ensuring it never enters the food chain.

6. Establish Verification Procedures

Verification is the process of "checking the system." We perform regular audits of the vessel's temperature logs and calibrate all on-board sensors before every departure. We also conduct periodic "Third-Party Validation," where samples from our wild-caught stock are sent to certified laboratories to be screened for heavy metals and pathogenic bacteria, proving that our on-board HACCP plan is effective.

7. Establish Record-Keeping and Documentation

In modern fisheries, documentation is synonymous with Traceability. We maintain a "Vessel Trip Report" that includes:

- Catch location (GPS coordinates).

- Time of harvest and time of first chilling.

- Continuous temperature logs of the storage holds.

- Records of cleaning and sanitation of the deck. This "Paper Trail" allows a consumer at a restaurant to potentially trace their fillet back to the specific vessel and the date it was caught in the middle of the ocean.