From Ocean to Table: A Comprehensive Guide to Processing Grouper Fish

By. Lutfi - 04 Feb 2026

From Ocean to Table: A Comprehensive Guide to Processing Grouper Fish

Grouper, known for its firm texture and mild, sweet flavor, is one of the most sought-after catches in the global seafood market. Whether it is the prized Coral Trout or the massive Giant Grouper, this fish requires meticulous handling to preserve its premium quality. Proper processing—from the moment it leaves the water to its final packaging—is a delicate balance of science, hygiene, and culinary art.

This article explores the essential stages of grouper processing, ensuring that the final product meets the high standards expected by chefs and consumers worldwide.

1. Pre-Processing: The Importance of Immediate Care

The quality of a grouper fillet is largely determined in the first few minutes after harvest. Because grouper are often caught in deep or tropical waters, temperature control is the biggest challenge.

- Icing and Chilling: Immediately after being caught, the fish should be placed in a slurry of ice and seawater. This "thermal shock" stops metabolic processes that lead to spoilage.

- Bleeding (Ikejime): In high-end markets, the Japanese method of Ikejime is often used. By quickly spiking the brain and bleeding the fish, processors prevent the buildup of lactic acid and ammonia, resulting in a cleaner taste and a longer shelf life.

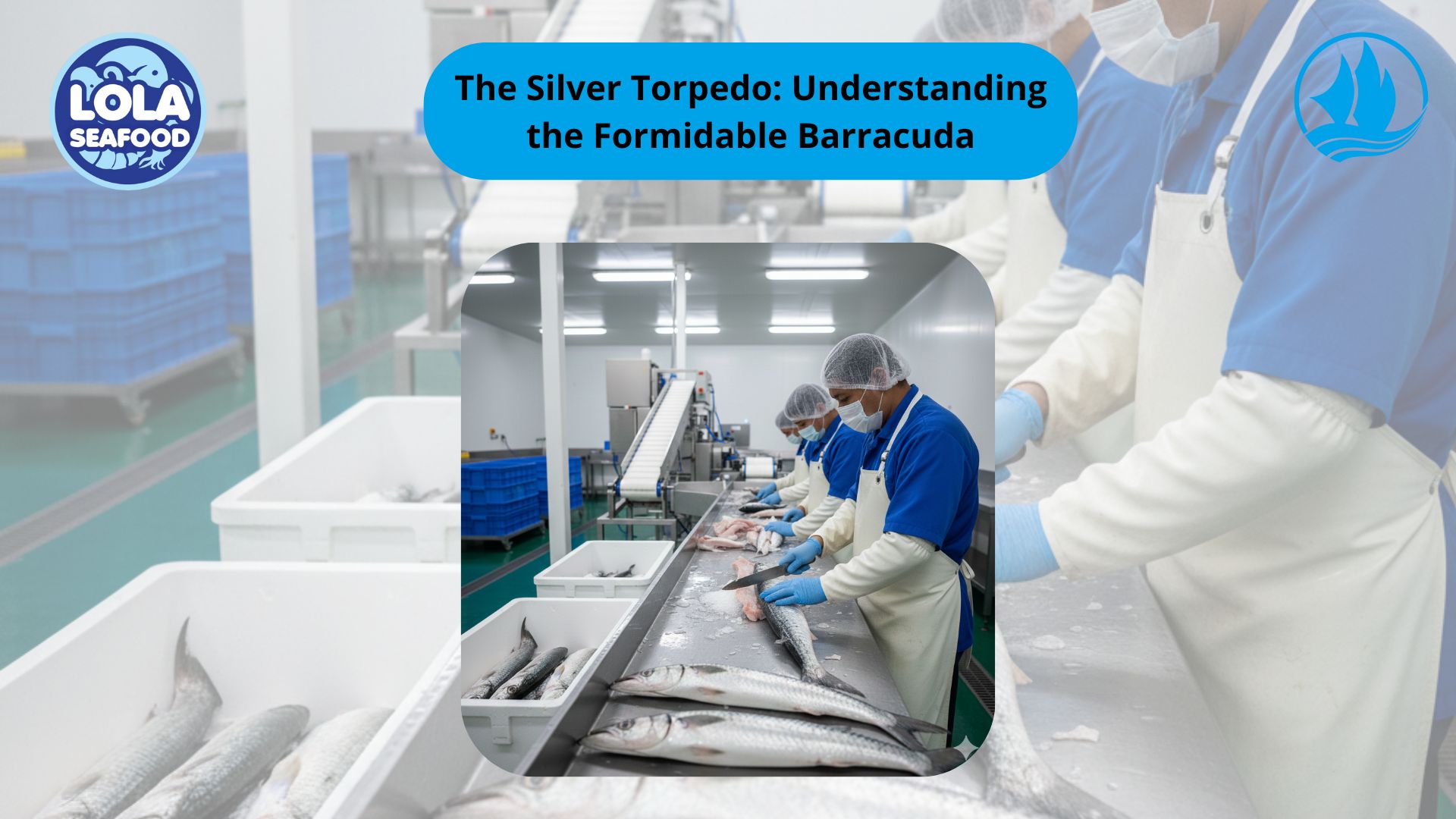

2. Primary Processing: Cleaning and Preparation

Once the grouper reaches the processing facility, it undergoes primary cleaning. This stage is crucial for food safety and involves several physical steps:

- Scaling: Grouper scales are tough and deeply embedded. Specialized mechanical scalers or high-pressure water jets are often used in industrial settings to remove them without damaging the skin.

- Gutting and Topping: The entrails and head are removed. During this stage, processors must be careful not to puncture the gall bladder, as the bile can stain the flesh and create a bitter flavor.

- Washing: The carcasses are washed with chilled, chlorinated water (or ozonated water) to eliminate surface bacteria.

3. Secondary Processing: The Art of Filleting

This is where the value is added. Grouper is versatile, but its anatomy requires a skilled hand.

- Filleting: Unlike flatfish, the grouper has a sturdy rib cage. Processors use flexible filleting knives to glide along the backbone, ensuring maximum meat recovery.

- Skinning: Depending on market demand, the skin may be left on (common for grilling) or removed. If the skin is kept, it must be perfectly "scaled" to ensure it becomes crispy when cooked.

- Pin Bone Removal: Grouper fillets contain a row of small intramuscular bones. These are typically removed using specialized tweezers or a "V-cut" to ensure a "boneless" dining experience.

4. Preservation Techniques: Keeping it Fresh

Since grouper is often exported across continents, preservation is the backbone of the industry.

|

Method |

Description |

Best For |

|

Chilled |

Kept at $0^\circ\text{C}$ to $4^\circ\text{C}$ on ice. |

Local markets and high-end restaurants. |

|

IQF (Individual Quick Frozen) |

Each fillet is frozen rapidly at $-35^\circ\text{C}$ or lower. |

Exporting to retail and supermarkets. |

|

Glazing |

A thin layer of ice is applied to the frozen fish. |

Preventing freezer burn and dehydration. |

5. Quality Control and Safety Standards

Grouper processing must adhere to strict international regulations, such as HACCP (Hazard Analysis and Critical Control Points). One specific concern with large reef fish like grouper is Ciguatera, a toxin produced by certain algae. Professional processors source fish from "clean" zones and perform regular laboratory testing to ensure consumer safety.

Furthermore, weight consistency is key. Fillets are often graded by size (e.g., 6-8 oz, 8-10 oz) to provide uniform portions for the restaurant industry.

6. Sustainability and By-products

Modern processing doesn't stop at the fillet. To minimize waste, the industry has found uses for almost every part of the grouper:

- Heads and Bones: Often used to create high-quality fish stock or collagen extracts.

- Skin: Can be processed into leather or fried into "fish skin" snacks, a popular trend in Southeast Asia.

- Trimmings: Used for fish cakes or minced fish products.

The Deep-Sea Treasure of High-Quality Protein.jpg)