The Crimson Culinary Star: A Comprehensive Guide to Processing Red Snapper

By. Lutfi - 30 Jan 2026

The Crimson Culinary Star: A Comprehensive Guide to Processing Red Snapper

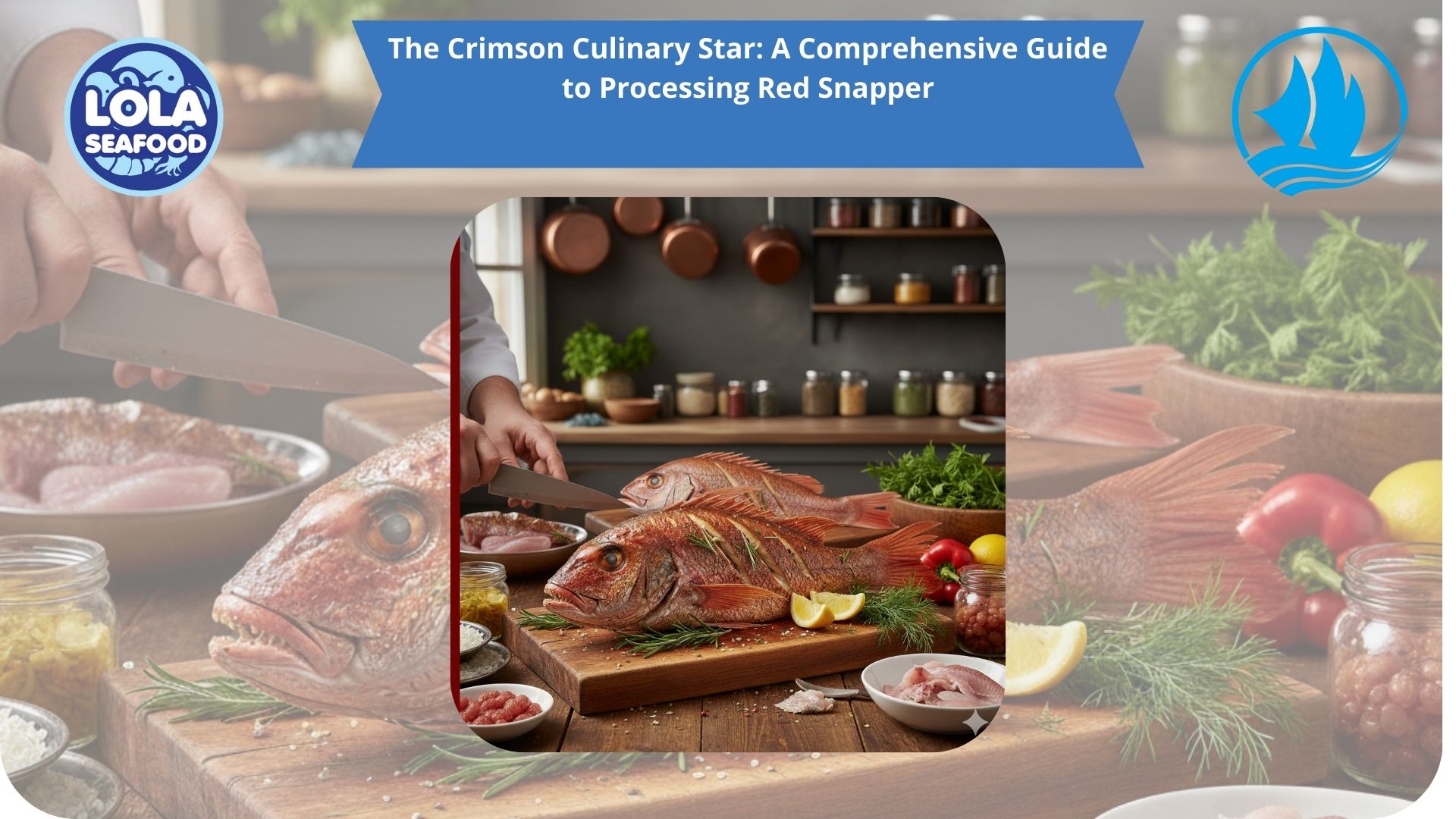

In the world of premium seafood, few fish command as much respect and appetite as the Red Snapper (Lutjanus campechanus). Known for its vibrant crimson scales, firm white flesh, and a delicate, nutty flavor profile, it is a centerpiece of coastal cuisines from the Gulf of Mexico to the tropical waters of Indonesia. However, bringing this fish from the ocean depths to a gourmet plate requires a meticulous journey of processing, preservation, and culinary technique.

1. From Sea to Shore: The Critical First Steps

The quality of a Red Snapper dish is decided the moment the fish leaves the water. Because Red Snapper is a deep-dwelling species, it is susceptible to rapid degradation if not handled correctly.

- Immediate Chilling: Professional fishers use a method called "slush icing"—a mixture of seawater and crushed ice—to bring the core temperature of the fish down to $0^{\circ}C$ immediately. This halts bacterial growth and preserves the muscle integrity.

- Ike Jime (Optional but Premium): High-end suppliers often use the Japanese Ike Jime technique, which involves a quick spike to the brain and bleeding the fish. This prevents the buildup of lactic acid, ensuring the meat remains sweet and firm.

2. Commercial Processing: Cleaning and Scaling

Once the fish reaches the processing facility, it undergoes several mechanical and manual stages. Red Snapper is unique because its skin is considered a culinary asset rather than a waste product.

- Descaling: Red Snapper scales are notoriously tough and armor-like. Processors use electric scalers or manual serrated tools to remove them without tearing the delicate skin. Keeping the skin intact is vital because it becomes crispy and flavorful when seared.

- Evisceration and Gilling: For "Whole Cleaned" exports, the guts and gills are removed through a small incision. It is crucial to clean the bloodline along the spine to prevent a "fishy" or metallic aftertaste.

- Filleting: For the retail market, the fish is often filleted. A skilled processor can achieve a high yield, ensuring that the thickest part of the loin remains uniform for even cooking.

3. Preservation and Cold Chain Management

Red Snapper is a global commodity, meaning it often travels thousands of miles. To maintain its "just-caught" quality, the cold chain must be unbreakable.

|

Method |

Description |

Best For |

|

Fresh Chilled |

Kept on ice at $0-2^{\circ}C$. |

Local markets and high-end restaurants. |

|

IQF (Individually Quick Frozen) |

Each fillet is frozen rapidly at $-40^{\circ}C$. |

Export and long-term storage without ice crystals. |

|

Vacuum Packaging |

Removing oxygen to prevent lipid oxidation. |

Retail packaging to extend shelf life. |

4. Preservation and Cold Chain Management

In the kitchen, Red Snapper is celebrated for its versatility. Its lean protein structure ($100$ grams of fish contains roughly $20$ grams of protein and only $1.5$ grams of fat) makes it a healthy yet satisfying choice.

The "Skin-On" Advantage

Most chefs prefer Red Snapper with the skin on. When the skin is scored with a knife and placed in a hot pan with olive oil or butter, the collagen renders out, creating a crackling texture that contrasts beautifully with the moist flakes of the meat.

Global Flavor Pairings

- The Mediterranean Style: Processed with lemon, garlic, and capers. The acidity of the lemon cuts through the natural sweetness of the snapper.

- The Southeast Asian Style: Often steamed whole with ginger, scallions, and soy sauce. In Indonesia, Kakap Merah is frequently grilled over coconut husks (Ikan Bakar) and served with a spicy Sambal Dabu-Dabu.

- The Caribbean Style: Deep-fried whole and served with "escovitch" vegetables—onions, carrots, and chayote pickled in vinegar and allspice.

5. Sustainability and Ethics in Processing

As demand for Red Snapper grows, processing now includes traceability. Responsible processors now label fish with QR codes that tell the consumer exactly where and how the fish was caught. This ensures that the Red Snapper on your plate isn't a victim of overfishing or "seafood fraud" (where cheaper fish like Tilapia or Rockfish are mislabeled as Snapper).