From Ocean to Plate: The Crucial Stages in Processing Export-Quality Red Snapper

By. Puji Widyastuti - 04 Feb 2026

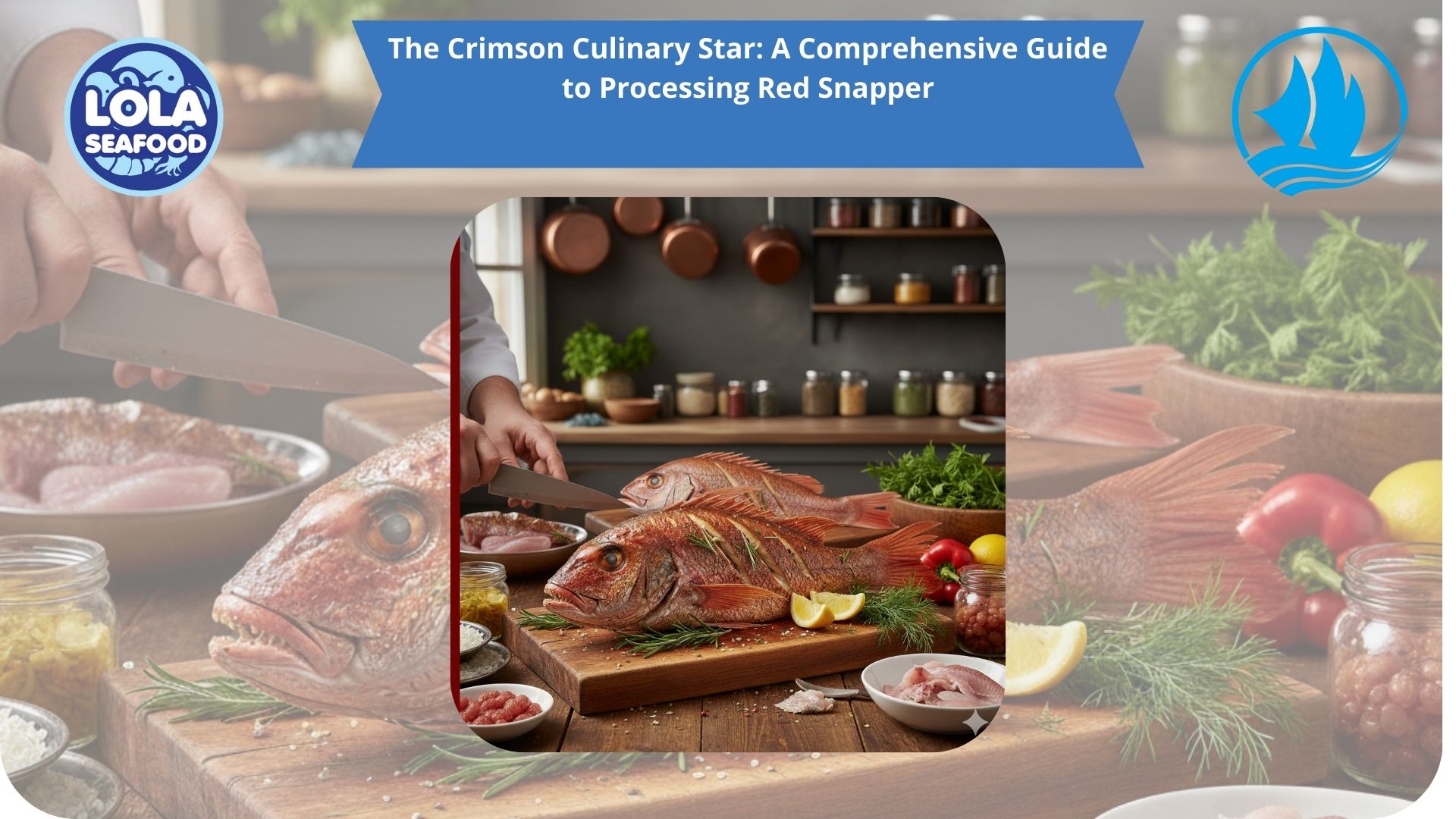

kelolalaut.com Red Snapper (Lutjanus campechanus) is more than just a menu item in high-end seafood restaurants; it is a premium global commodity. Known for its firm texture, sweet nutty flavor, and vibrant crimson skin, it is highly sought after in markets like the United States, Japan, and the European Union. However, the journey from the deep blue waters to an international dinner plate is a complex race against time and biology.

To meet "export-quality" standards, processing must go beyond simple cleaning. It requires a rigorous adherence to the Cold Chain System and Hazard Analysis Critical Control Point (HACCP) protocols. Here are the crucial stages that determine whether a Red Snapper is fit for the global stage.

1. Sustainable Harvesting and Immediate Handling

The quality of the fish is determined the moment it leaves the water. Export-grade snapper is typically caught using sustainable methods like longlines or handlines, which prevent the bruising and "crush" damage often associated with large-scale trawling.

Once on board, the Bleeding Process is vital. By cutting the gill arches immediately after harvest, processors ensure that blood is drained from the flesh. This prevents the "fishy" odor caused by blood oxidation and results in the pristine, white-to-pinkish flesh that premium buyers demand.

2. The Golden Rule: Temperature Control

If there is one factor that dictates the success of fish processing, it is temperature. Red Snapper is highly perishable. As soon as the fish dies, enzymes and bacteria begin to break down the protein structure.

- Pre-chilling: Immediately after bleeding, fish must be submerged in a slurry of ice and seawater (around 0°C to 1°C).

- The Cold Chain: This temperature must be maintained through transport to the processing facility. Any "temperature abuse"—even for thirty minutes—can trigger the production of histamine or other biogenic amines, leading to immediate rejection by international customs.

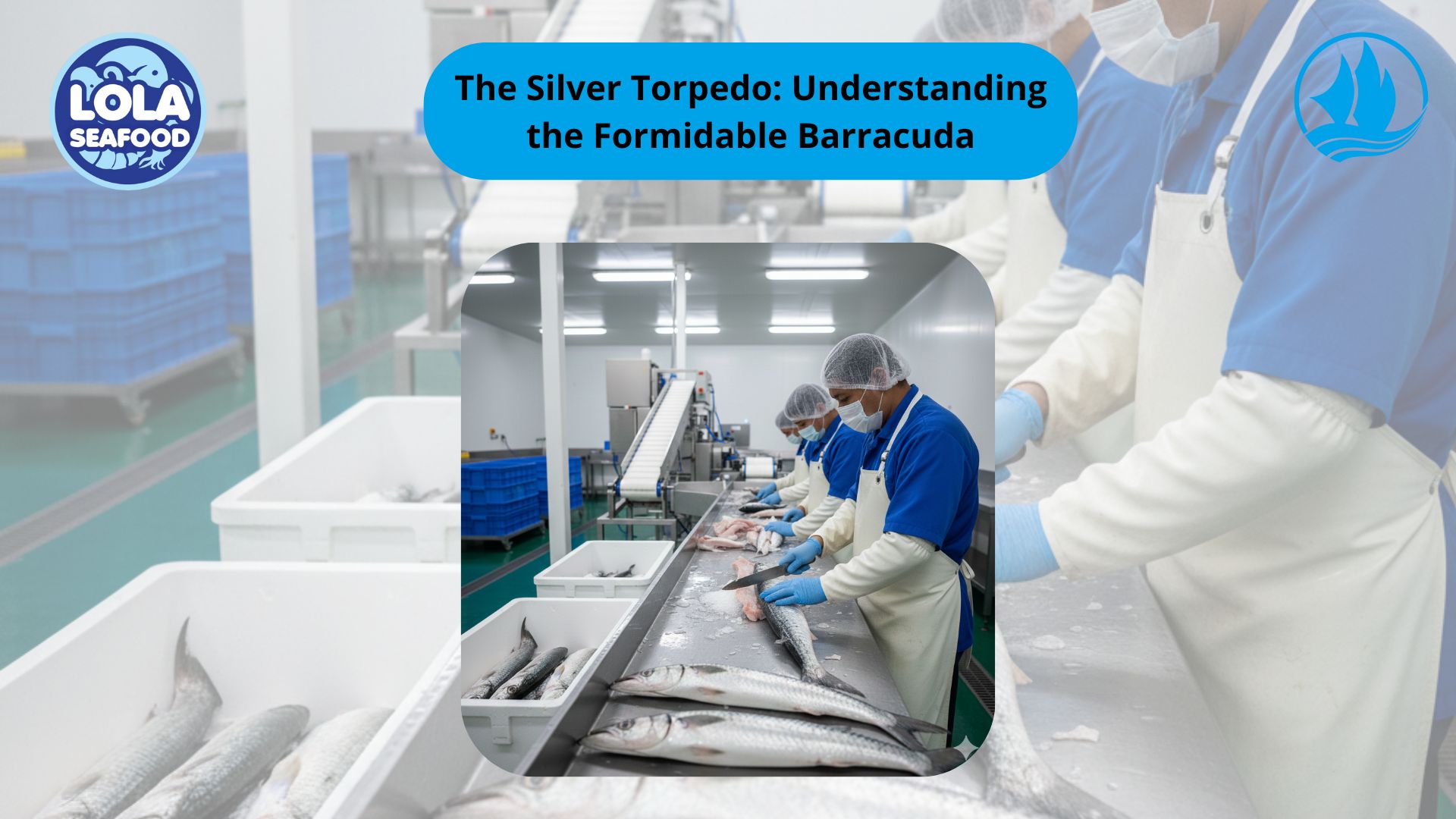

3. Receiving and Organoleptic Inspection

Upon arrival at the processing plant, the fish undergo a sensory (organoleptic) evaluation. Inspectors look for specific "Freshness Markers":

- Eyes: Must be clear, bright, and bulging (not cloudy or sunken).

- Gills: Should be bright red, not brown or grey.

- Elasticity: The flesh must spring back when pressed.

- Smell: It should smell like the ocean, never ammonia-like.

4. Precision Filleting and Trimming

For the export market, presentation is everything. Whether the product is "Gilled and Gutted" (G&G) or "Skin-on Fillets," the butchery must be surgical.

In the filleting stage, workers use specialized knives to remove the meat from the bone with minimal "gaping" (tearing of the muscle fibers). For "Deep Skinned" fillets, the dark lateral line—the fat-rich tissue—is often removed to extend shelf life and improve flavor profile. Every fillet is then inspected under high-intensity light for parasites or bone fragments using a process called Candling.

5. Advanced Freezing Techniques: IQF vs. Blast Freezing

To maintain the cell structure of the Red Snapper, the freezing process must be rapid. Standard home freezers create large ice crystals that puncture cell walls, leading to "drip loss" (mushy texture) when thawed.

Export facilities use Individual Quick Freezing (IQF) or Air Blast Freezers reaching temperatures of 35oC – 40oC This speed ensures that ice crystals remain microscopic, preserving the natural texture and moisture of the fish as if it were fresh from the sea.

6. Glazing and Vacuum Packaging

To prevent "Freezer Burn"—dehydration caused by cold air—frozen snapper is often given a Water Glaze. This thin layer of ice acts as a protective shield. The product is then vacuum-sealed in high-barrier plastic to eliminate oxygen, which is the primary catalyst for fat rancidity.

7. Traceability and Certification

Modern export markets demand to know the "who, when, and where." Each batch is assigned a tracking code that links the final package back to the specific vessel and fishing zone. Without proper documentation (such as Health Certificates and Catch Certificates), even the highest quality fish cannot enter regulated international markets.

The Deep-Sea Treasure of High-Quality Protein.jpg)