Why Integrated Pest Management (IPM) Matters in the Seafood Industry

By. Ely Kusniawati - 18 Sep 2025.jpg)

Kelolalaut.com The seafood industry is one of the fastest-growing segments of the global food market, providing millions of tons of fish and seafood products every year. However, this industry also faces significant challenges when it comes to maintaining hygiene and ensuring food safety. Fish and seafood are highly perishable, nutrient-dense, and often processed in environments that are humid and full of organic residues—conditions that are highly attractive to pests. This is where Integrated Pest Management (IPM) plays a vital role.

Understanding Integrated Pest Management (IPM)

Integrated Pest Management is a holistic and science-based approach to pest control. Unlike conventional methods that rely heavily on chemical pesticides, IPM emphasizes prevention, monitoring, and the careful use of targeted measures only when necessary. The principle behind IPM is simple: rather than reacting to pest problems after they occur, it is more effective and sustainable to prevent infestations in the first place.

In seafood facilities, this approach is particularly important because excessive use of chemicals could contaminate fish products, harm workers, and even compromise compliance with international food safety standards. IPM allows seafood processors to protect their products while reducing environmental impact.

Why IPM is Crucial in Seafood Processing

- Protecting Product Quality and Safety

Pests such as rodents, flies, and cockroaches carry pathogens like Salmonella, E. coli, and Listeria. These microorganisms can contaminate fish fillets, frozen seafood, or dried fish products in just minutes. Even a single trace of pest contamination can result in product recalls, export rejections, and financial losses. By applying IPM, seafood companies can safeguard their products from these invisible threats.

- Ensuring Regulatory Compliance

Most global markets, including the United States, European Union, and Japan, require strict adherence to HACCP (Hazard Analysis Critical Control Point) and Good Manufacturing Practices (GMP). Pest control is a mandatory component of these systems. IPM provides a structured, documented process that demonstrates compliance during audits, which is crucial for maintaining market access.

- Reducing Dependence on Chemicals

Overuse of pesticides is risky in seafood plants. Chemical residues may remain on packaging, surfaces, or even seafood products themselves. Such contamination is not only dangerous for consumers but also a violation of international safety standards. IPM minimizes chemical use by relying first on exclusion methods, sanitation practices, and biological controls. Pesticides are used only as a last resort and under strict regulation.

- Protecting Reputation and Consumer

In today’s digital era, negative news about pest infestations can spread quickly. A viral story about rodents or insects found in seafood packaging can destroy consumer confidence overnight. By implementing IPM, seafood companies show their commitment to hygiene, sustainability, and food safety—key factors that strengthen consumer trust and brand reputation.

Key Components of IPM in Seafood Facilities

To be effective, IPM in seafood processing must combine several strategies:

- Facility Design and Maintenance: Buildings should be designed to limit pest entry. This includes sealed cracks, air curtains at loading docks, proper drainage systems, and self-closing doors.

- Sanitation and Waste Management: Fish residues, blood, and wastewater must be cleaned regularly. Waste bins should be covered and emptied frequently, as organic waste is the primary attraction for pests.

- Monitoring and Early Detection: Traps, glue boards, pheromone lures, and even digital monitoring sensors help detect pests before infestations grow. Inspection logs should be maintained for traceability.

- Targeted Control Measures: Physical barriers, biological methods, and mechanical traps are prioritized over chemicals. Approved pesticides may only be used when infestations cannot be controlled by other means.

- Employee Training and Awareness: Staff must be trained to identify pest signs, such as droppings or gnaw marks, and report them immediately. Everyone in the facility shares responsibility for maintaining a pest-free environment.

Case Example: Cold Storage and IPM

Cold storage units are critical for seafood preservation, yet they are also vulnerable to pests. The constant opening of doors allows flies and rodents to enter, while condensation and packaging residues create favorable conditions. With IPM, companies can reduce these risks by sealing entry points, maintaining temperature control, and ensuring proper stock rotation to avoid spoilage. This reduces waste and protects product yield.

Long Term Benefits of IPM

Adopting IPM in seafood facilities provides both immediate and long-term benefits:

- Cost Savings: Preventing infestations is cheaper than dealing with recalls, export rejections, or reputational damage.

- Market Access: IPM ensures compliance with HACCP and GMP, making it easier to maintain access to international markets.

- Sustainability: By reducing reliance on chemicals, IPM aligns with global sustainability goals and environmental protection.

- Employee Morale: Workers in pest-free environments feel safer, more confident, and more motivated to maintain hygiene standards.

Integrated Pest Management (IPM) is more than just a technical requirement—it is a strategic necessity in the seafood industry. By focusing on prevention, sustainability, and compliance, IPM protects seafood products from contamination, ensures consumer safety, and strengthens global market trust. For companies that want to remain competitive in an increasingly regulated and transparent food market, implementing IPM is not optional—it is essential for long-term success.

If youre interested in our Mahi-Mahi Fillet Skinless please do not hesitate to contact us through email and/or Whatsapp

The Dominance of Demersal Fish: The Strategic Export Potential of Indonesia’s Grouper and Parrotfish

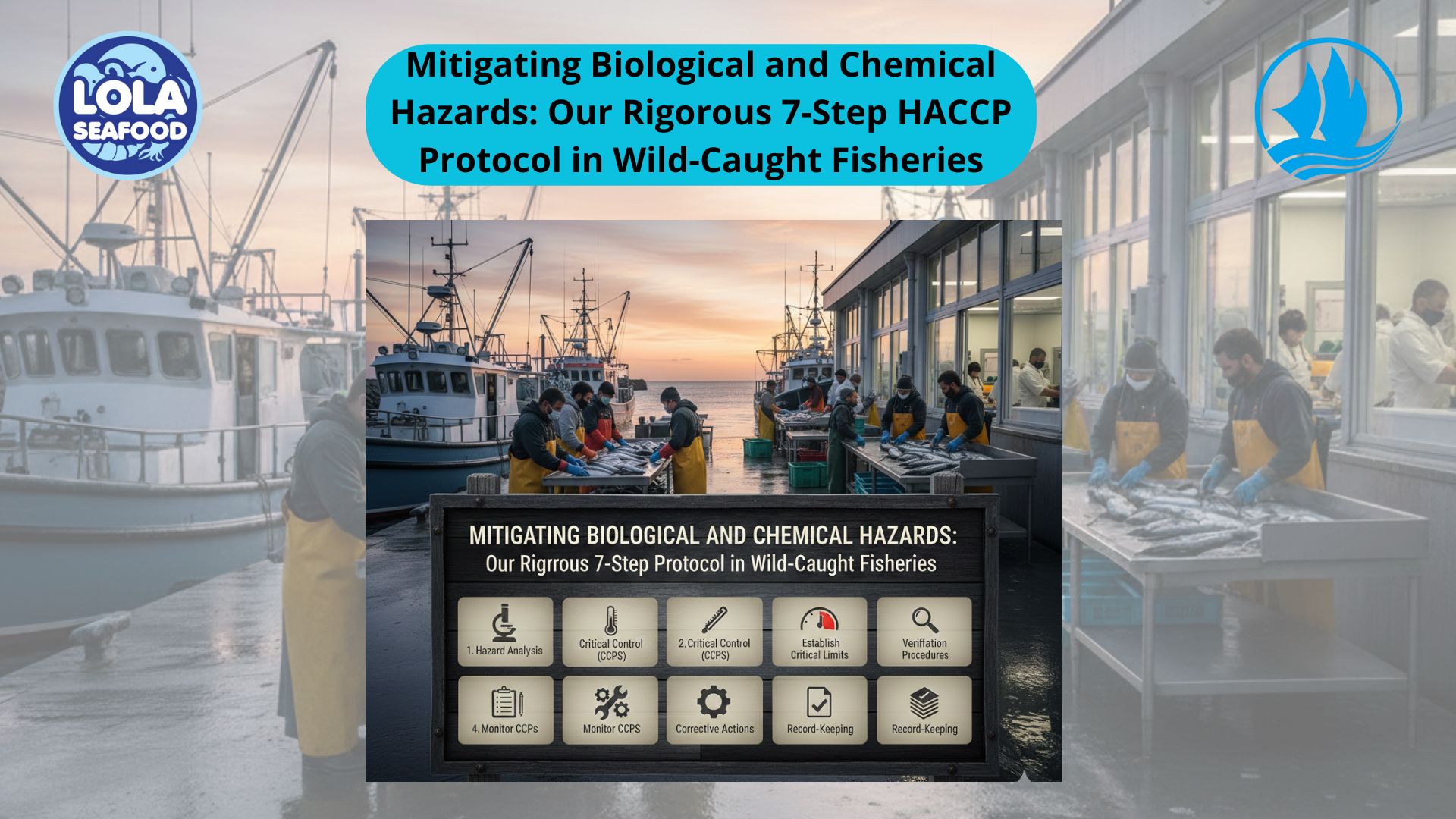

Mitigating Biological and Chemical Hazards: Our Rigorous 7-Step HACCP Protocol in Wild-Caught Fisheries

.jpg)