CO Treated Fish: Balancing Market Appeal and Consumer Safety

By. Puji Widyastuti - 09 Sep 2025.jpg)

Kelolalaut.com In the global seafood industry, appearance plays a crucial role in consumer choices. Bright red tuna loins or fillets that maintain a “just caught” look are far more appealing on supermarket shelves compared to slightly browned or oxidized fish. To meet this demand, some processors use carbon monoxide (CO) treatment as part of their fish preservation process. While the treatment improves visual quality and marketability, it also raises ongoing debates about transparency, labeling, and consumer safety.

What Is CO Treatment in Fish Processing?

Carbon monoxide treatment involves exposing fish—commonly tuna and some other species—to a controlled atmosphere containing CO gas. This process stabilizes the red color of myoglobin in the fish muscle, preventing oxidation and discoloration. As a result, the fish retains its vibrant red hue, even after long storage periods under frozen conditions.

For processors and retailers, the main advantage is clear: fish looks fresher for longer, which can boost sales and reduce food waste.

Market Appeal: The Red Tuna Effect

The biggest driver of CO use is consumer preference. Studies show that buyers often associate redness in tuna with freshness and higher quality. A CO-treated tuna fillet may look nearly identical to freshly caught fish, even after weeks of storage.

This has clear benefits for international seafood trade, particularly for markets like the United States, Japan, and Europe, where demand for visually appealing seafood is high. Retailers gain an extended window to sell their products, and exporters can maintain product appeal during long shipping periods.

Safety Considerations and Concerns

Although CO treatment does not introduce toxic residues into the fish itself, it can pose indirect risks. The main concern is misleading appearance. A fish may look perfectly fresh on the outside while, in reality, it has aged or degraded in quality. This could make it harder for consumers—and sometimes even inspectors—to judge true freshness by visual cues alone.

In extreme cases, improperly stored fish could develop harmful microbial contamination despite still looking red and fresh due to CO stabilization. This has led some countries, such as the European Union, to heavily restrict or ban CO-treated fish products.

Global Regulatory Landscape

The acceptance of CO-treated fish varies widely across regions:

- United States: CO treatment is permitted under the FDA’s “Generally Recognized as Safe” (GRAS) status, provided it is not misleading to consumers.

- European Union: CO treatment is banned, with authorities citing consumer deception risks.

- Japan: Regulations are stricter, and many retailers avoid CO-treated tuna to maintain consumer trust.

- Other regions: Rules depend on local food safety agencies and trade policies, often influenced by export destinations.

This patchwork of regulations has created both challenges and opportunities for the seafood trade, as exporters must adapt their processing methods depending on their target markets.

Striking the Balance: Transparency and Innovation

The ongoing debate about CO-treated fish reflects a larger challenge in the seafood industry: balancing consumer appeal with transparency and safety. While CO treatment can reduce waste and improve marketability, it should always be accompanied by clear labeling and strict handling practices.

Some companies are exploring alternatives, such as natural antioxidants, improved freezing techniques, and packaging innovations, to achieve similar effects without regulatory hurdles.

CO-treated fish highlights the delicate balance between innovation and responsibility in seafood processing. While the method undeniably enhances market appeal by preserving the visual quality of fish, its risks lie in the potential for misleading consumers about freshness. Ultimately, the future of CO-treated fish depends on global consensus, stricter monitoring, and perhaps the development of safer, more transparent preservation technologies.

If youre interested in our Corvina / Croaker / Jewfish Whole Round / Whole Gilled Gutted Scale , Corvina / Croaker / Jewfish Fillet Skin On and Corvina Fillet Skin Patch please do not hesitate to contact us through email and/or whatsapp

The Dominance of Demersal Fish: The Strategic Export Potential of Indonesia’s Grouper and Parrotfish

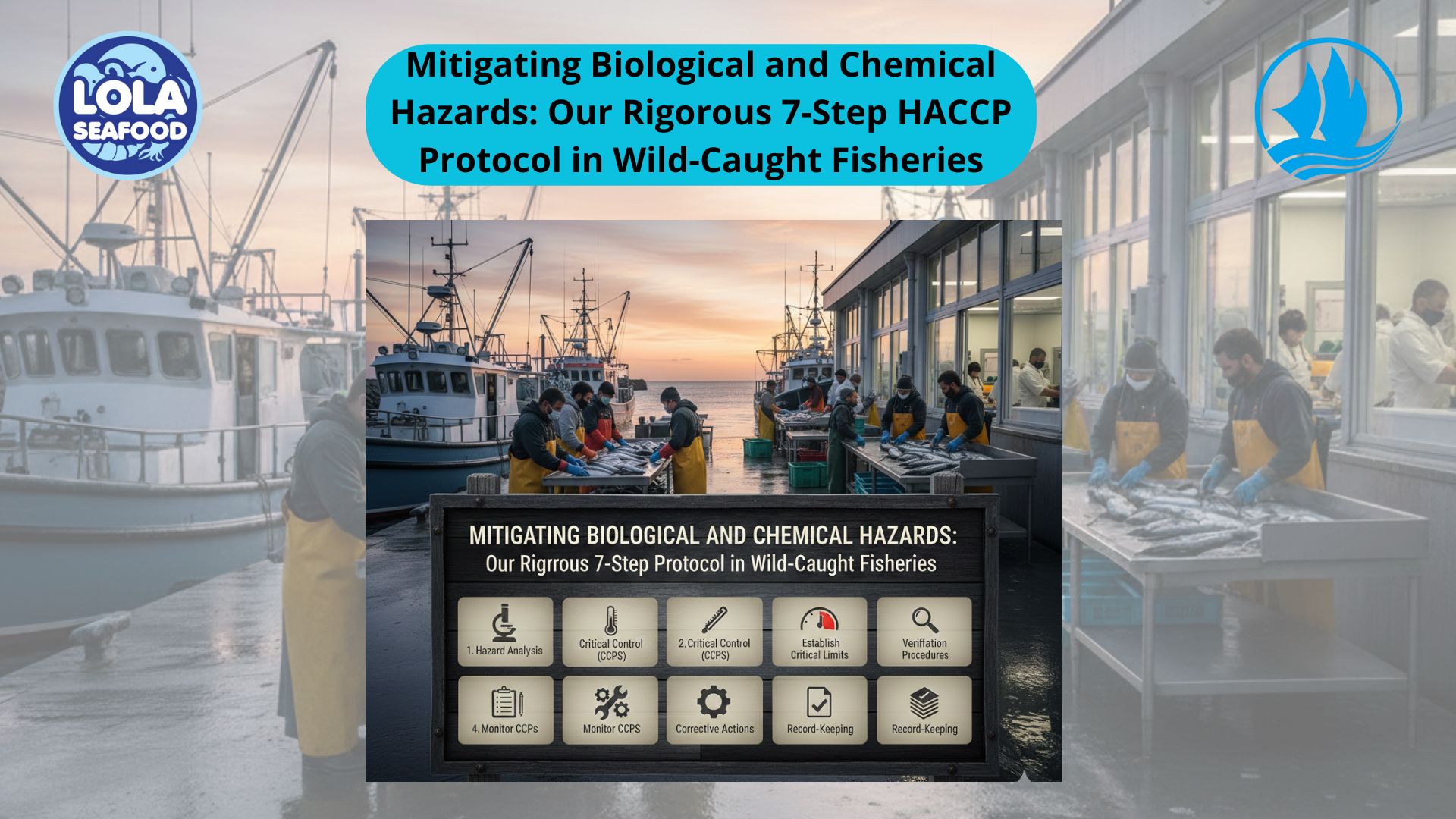

Mitigating Biological and Chemical Hazards: Our Rigorous 7-Step HACCP Protocol in Wild-Caught Fisheries

.jpg)