The 7 Principles of HACCP: Building a Safer Food System

By. Nugroho Luhur - 04 Sep 2025.jpg)

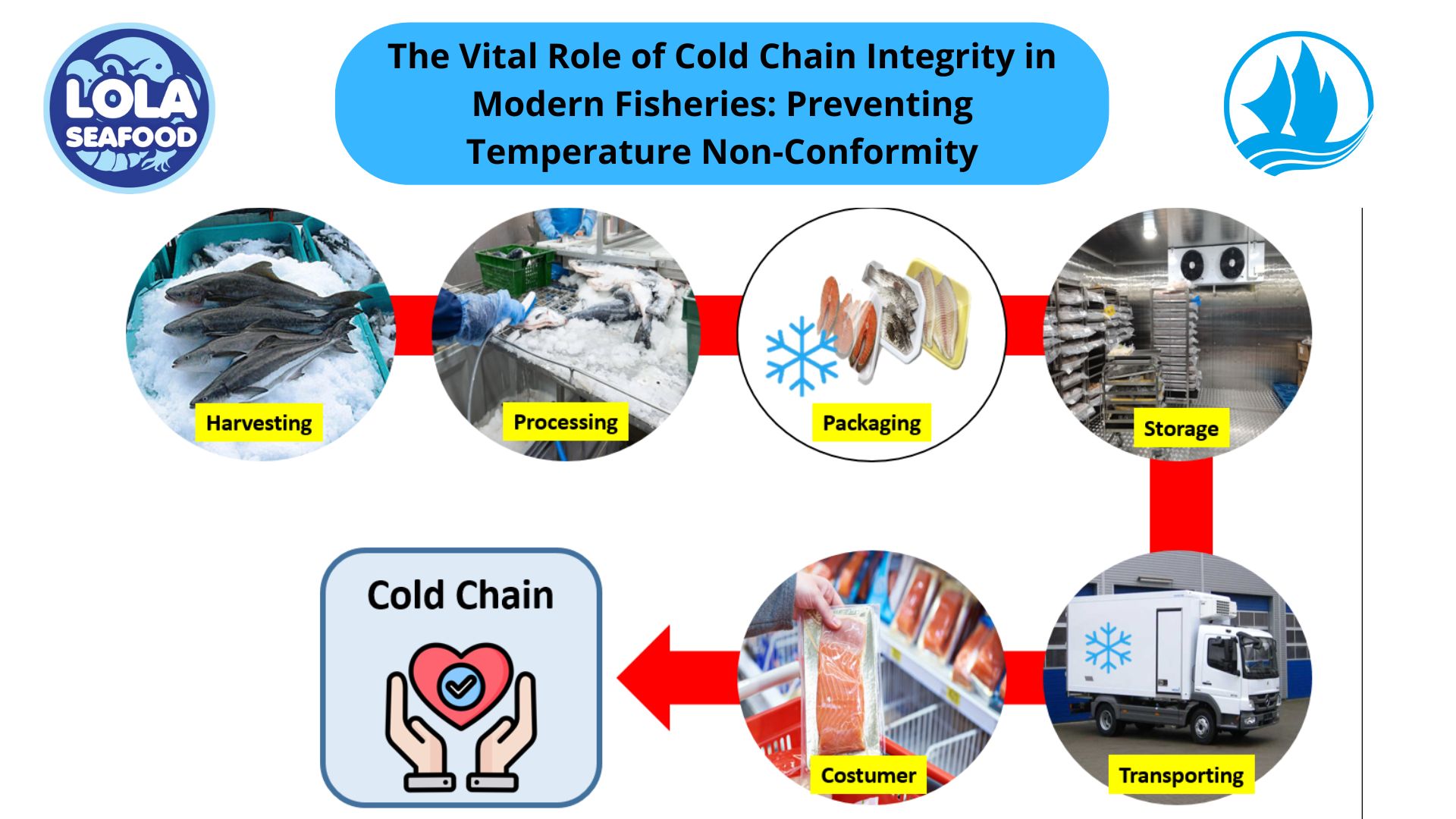

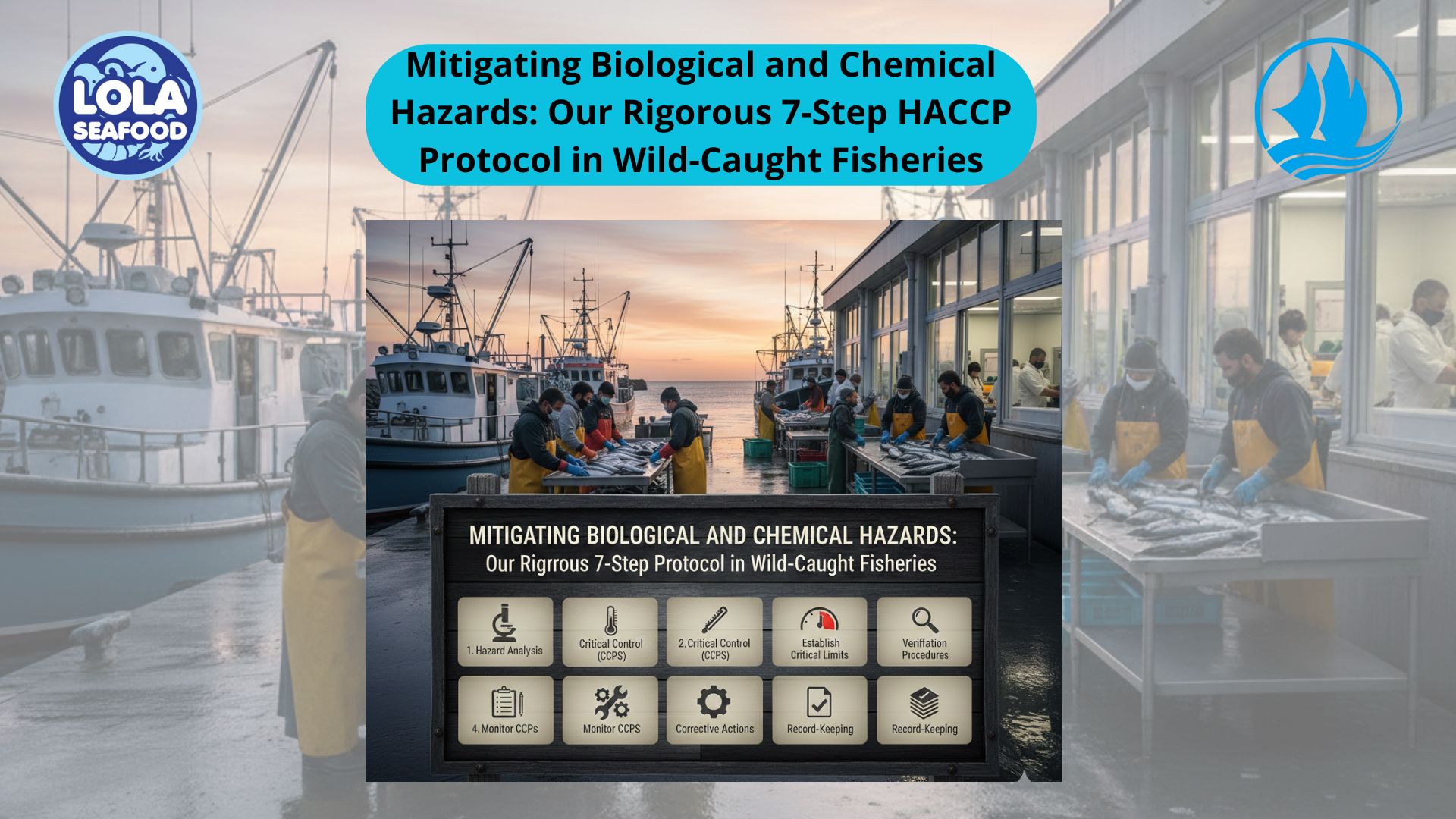

Kelolalaut.com Food safety is an essential concern for producers, regulators, and consumers alike. Outbreaks of foodborne illness not only endanger public health but also damage consumer confidence and disrupt trade. To address these challenges, the food industry relies on HACCP (Hazard Analysis and Critical Control Points), a preventive system designed to manage risks before they compromise food safety. At the heart of HACCP are seven principles, each providing a structured approach to identifying, controlling, and verifying food safety hazards.

1. Conduct a Hazard Analysis

The first principle is about identifying hazards that could occur at any point in the production process. Hazards fall into three main categories namely biological hazards, such as Salmonella, Listeria, and Vibrio bacteria, chemical hazards, including pesticide residues, allergens, and cleaning agents, physical hazards, like fragments of glass, metal, or plastic. By carefully examining every stage—raw materials, processing, packaging, and distribution—producers can predict where problems might arise. This analysis is the foundation of the entire HACCP system, ensuring that potential risks are recognized before they can cause harm.

2. Determine Critical Control Points (CCPs)

Not every step in production is equally risky. Some points are especially crucial for preventing or eliminating hazards, and these are called Critical Control Points (CCPs). For example cooking seafood to the correct internal temperature kills harmful microorganisms, maintaining refrigeration below 4°C prevents bacterial growth, filtering water removes physical impurities, identifying CCPs allows producers to focus resources where they have the greatest impact on safety.

3. Establish Critical Limits

Once CCP are determined, specific standards—known as critical limits—must be set. These limits act as boundaries between safe and unsafe. They are measurable values such as temperature, time, pH, or chemical concentration. Examples include freezing seafood to at least -18°C for safe storage, ensuring the pH of a product stays below 4.6 to prevent microbial growth and cooking poultry to an internal temperature of 74°C (165°F). Setting clear limits ensures consistency, accountability, and scientific reliability in the production process.

4. Establish Monitoring Procedures

Monitoring ensures that each CCP remains within its critical limit. Without monitoring, there is no way to know whether safety standards are consistently met. Monitoring may involve recording refrigeration temperatures daily, using time–temperature indicators during cooking and conducting regular pH or chlorine level tests. Monitoring not only provides real-time assurance but also generates records that serve as evidence of compliance.

5. Establish Corrective Actions

Even the best systems may face occasional deviations. When monitoring shows that a CCP has exceeded its critical limit, corrective actions must be taken immediately. For instance: reprocessing or re-cooking food that has not reached the proper temperature, discarding spoiled or contaminated raw materials, adjusting equipment to restore the correct conditions. The goal of corrective actions is twofold: to ensure that unsafe food does not reach consumers and to fix the root cause of the deviation.

6. Establish Verification Procedures

Verification goes a step beyond monitoring. It ensures that the HACCP system is not only being followed but also functioning effectively. Verification activities may include: Reviewing monitoring logs., calibrating thermometers and equipment, conducting microbial tests on final products and performing internal audits of the HACCP plan. Verification builds confidence that the system is working as intended and highlights areas for improvement.

7. Establish Documentation and Record Keeping

The final principle emphasizes the importance of proper documentation. Without records, it is impossible to prove that food safety procedures are in place and functioning. Documentation may include hazard analyses and CCP identification, monitoring records and corrective action logs and verification reports and equipment calibration records. These documents not only ensure transparency and accountability but also provide evidence during audits and regulatory inspections.

If youre interested in our Gummy Shark Fillet please do not hesitate to contact us through email and/or whatsapp

The Dominance of Demersal Fish: The Strategic Export Potential of Indonesia’s Grouper and Parrotfish

Mitigating Biological and Chemical Hazards: Our Rigorous 7-Step HACCP Protocol in Wild-Caught Fisheries

.jpg)