ABF vs Cold Storage: Choosing the Right Freezing Method for Seafood Quality

By. Sofie Thoriq - 03 Sep 2025.jpg)

Kelolalaut.com Seafood is among the most valuable and perishable food commodities traded worldwide. Its high protein content, rich water composition, and delicate texture make it prone to rapid spoilage if not handled properly. To ensure safety and maintain quality, the seafood industry relies heavily on freezing technology. Two of the most widely used methods are Air Blast Freezing (ABF) and Cold Storage. While both are essential in modern fish processing, they serve different purposes and have distinct impacts on product quality. Understanding these differences is crucial for seafood producers, exporters, and consumers alike.

What Is Air Blast Freezing (ABF)?

Air Blast Freezing, or ABF, is a rapid freezing technique where seafood is exposed to high-velocity cold air, usually at temperatures ranging from –35°C to –45°C. The strong airflow ensures that heat is quickly removed from the product, allowing fish or fillets to reach the target core temperature in a matter of hours.

The speed of ABF prevents the formation of large ice crystals inside the fish’s tissues. Instead, only tiny crystals form, which helps preserve the natural texture, flavor, and nutritional value of the seafood. For premium exports like tuna, salmon, or shrimp, ABF is the preferred freezing method.

What Is Cold Storage?

Cold Storage, on the other hand, is primarily a preservation system rather than a rapid freezing method. Cold storage facilities maintain seafood at controlled low temperatures, typically between –18°C and –25°C. These conditions keep frozen products stable and extend their shelf life for weeks or months.

Unlike ABF, Cold Storage does not freeze the product quickly. Instead, it maintains the temperature of already frozen seafood, preventing spoilage and ensuring consistent product quality during storage and distribution.

Key Differences Between ABF and Cold Storage

Although both ABF and Cold Storage are integral to seafood processing, their roles are not interchangeable. Here are the main differences:

1. Freezing Speed

- ABF: Rapid freezing, reaching target temperature in hours.

- Cold Storage: Slow cooling, used only for holding frozen products.

2. Ice Crystal Formation

- ABF: Produces small ice crystals, protecting cell structures and texture.

- Cold Storage: If used as the first freezing method, large ice crystals form, leading to texture damage.

3. Product Quality

- ABF: Maintains fresh-like taste, firmness, and appearance.

- Cold Storage: Maintains stability but cannot improve or preserve freshness if quality is already compromised.

4. Purpose

- ABF: Designed for quick freezing immediately after catch or processing.

- Cold Storage: Designed for long-term preservation after ABF or other freezing methods.

5. Energy Use

- ABF: Higher energy consumption during operation due to powerful fans and extremely low temperatures.

- Cold Storage: Lower energy demand since it only maintains a stable cold environment.

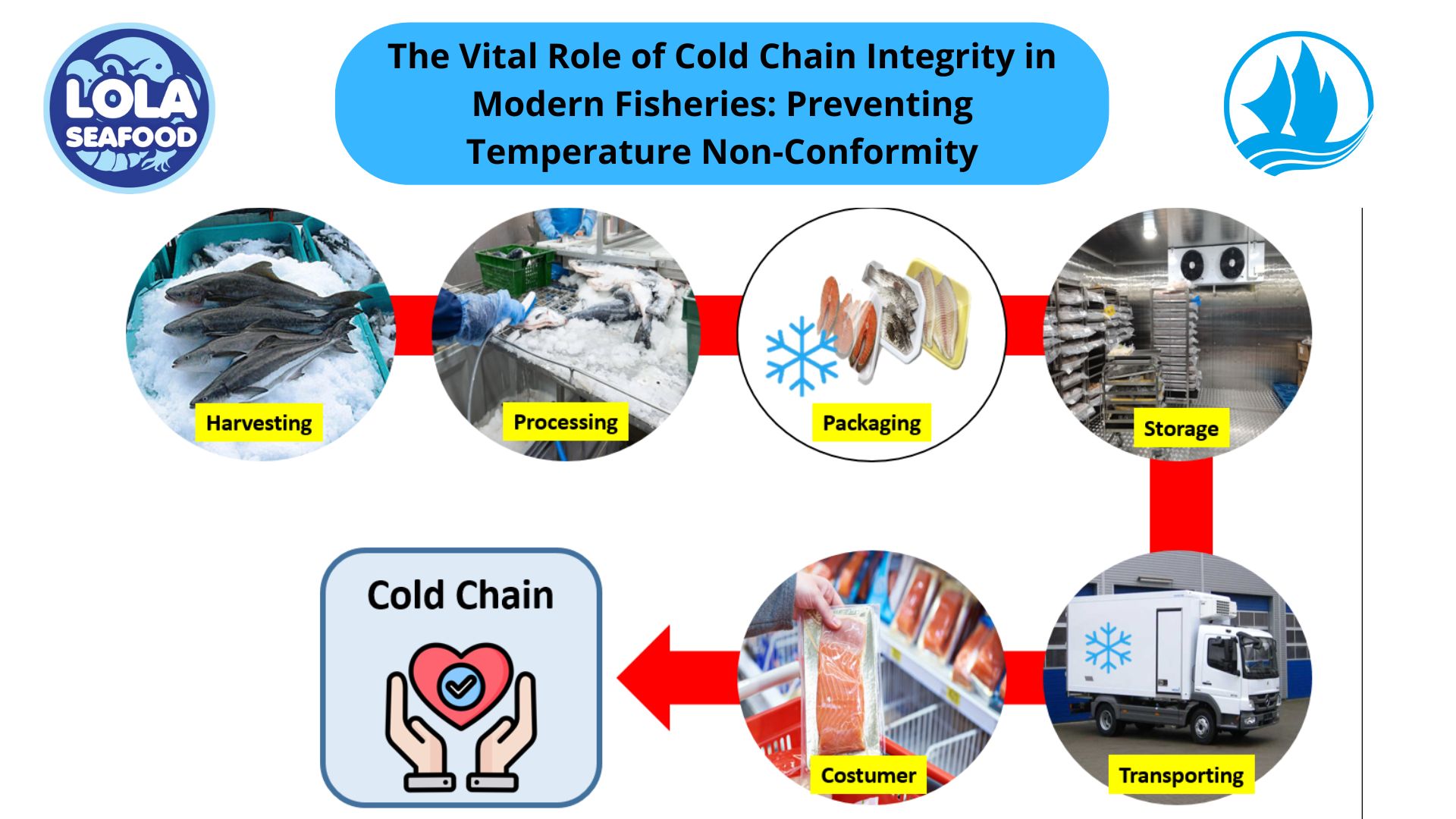

How ABF and Cold Storage Work Together

While ABF and Cold Storage have different roles, they are complementary in the seafood supply chain. Typically, freshly caught or processed fish is first frozen using ABF to lock in freshness. After this rapid freezing stage, the products are transferred into Cold Storage rooms, where they are safely kept until distribution.

This combination ensures that seafood products reach consumers with minimal quality loss, retaining their natural flavor, texture, and nutritional value even after long-distance shipping.

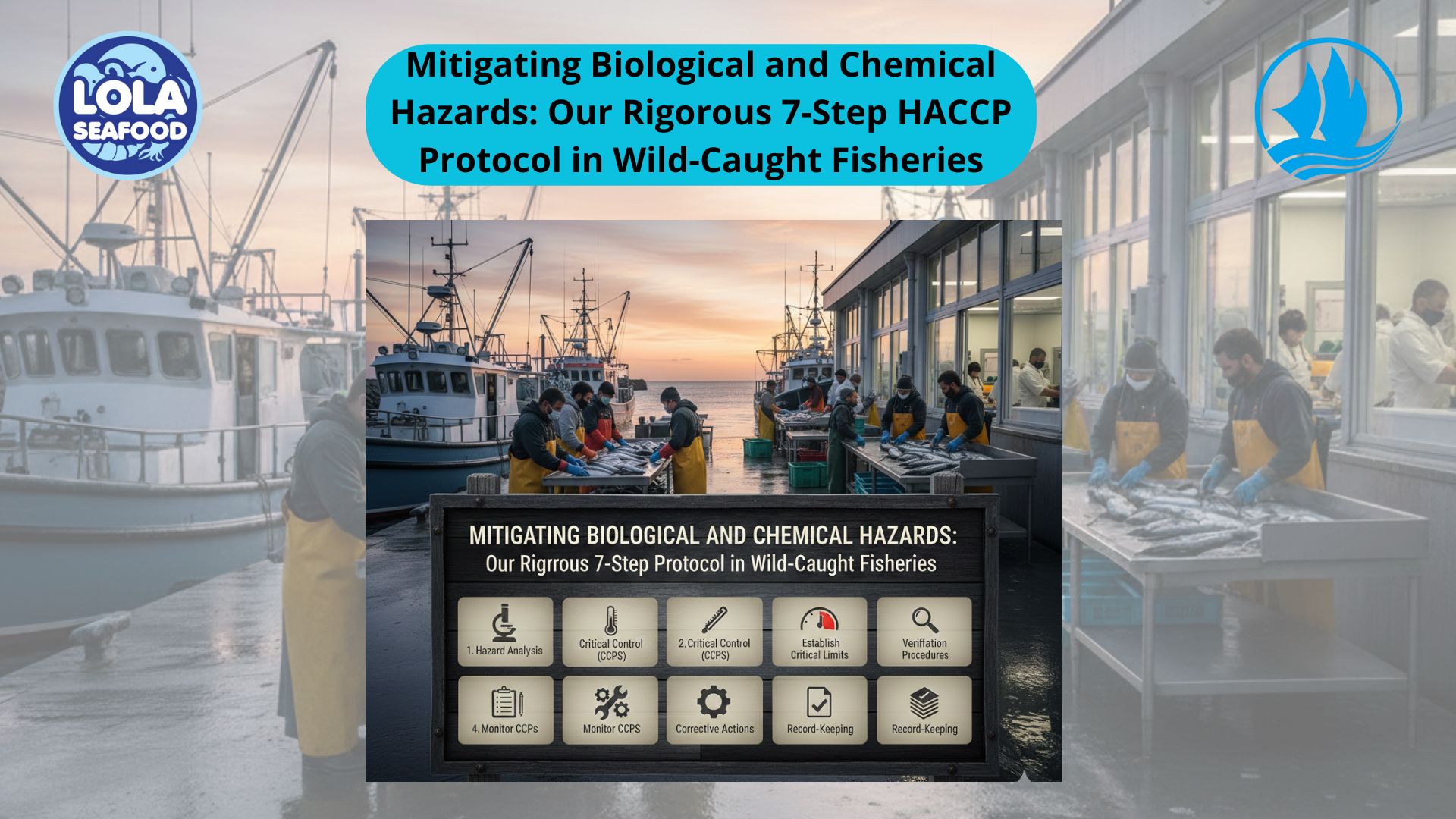

Meeting HACCP and Export Standards

International markets, especially the EU, US, and Japan, have strict regulations regarding seafood freezing and storage. HACCP systems require processors to demonstrate that proper freezing methods are in place to control microbial hazards and maintain product integrity.

- ABF helps meet critical limits for rapid freezing, minimizing bacterial growth and preventing enzymatic spoilage.

- Cold Storage ensures that the frozen state is consistently maintained, preventing thawing and refreezing that can harm product quality.

Together, they provide compliance with Codex Alimentarius guidelines and national standards such as FDA regulations or EU food safety directives.

Choosing the right freezing method is not about selecting between ABF and Cold Storage, but about understanding their complementary roles. ABF is essential for rapid freezing and quality preservation, while Cold Storage ensures stability and long-term preservation.

For seafood processors, exporters, and retailers, the smart integration of these two technologies ensures that products remain safe, nutritious, and of the highest quality by the time they reach global consumers. Ultimately, the success of the seafood industry depends on using both ABF and Cold Storage as partners in protecting freshness from ocean to table.

If youre interested in our Halibut Fillet Skinless please do not hesitate to contact us through email and/or whatsapp

The Dominance of Demersal Fish: The Strategic Export Potential of Indonesia’s Grouper and Parrotfish

Mitigating Biological and Chemical Hazards: Our Rigorous 7-Step HACCP Protocol in Wild-Caught Fisheries

.jpg)