Fresh-Up Water Practices: Meeting HACCP and International Standards in Seafood

By. Nugroho Luhur - 03 Sep 2025.jpg)

Kelolalaut.com Seafood is one of the most sensitive commodities in the global food industry. It is highly nutritious, but also highly perishable, making it vulnerable to contamination and spoilage if not handled properly. In fish processing plants, every stage of production must be carefully monitored, from receiving raw fish to packaging the final product. One critical but sometimes underestimated element in this chain is the use of fresh-up water. More than just a washing medium, fresh-up water plays a central role in ensuring seafood safety and maintaining compliance with HACCP (Hazard Analysis and Critical Control Point) systems as well as international food safety standards.

What Is Fresh-Up Water?

Fresh-up water refers to potable, treated water specifically used for rinsing, washing, or refreshing fish and fishery products during processing. It differs from regular water in that it must consistently meet strict microbiological, physical, and chemical standards. In many facilities, fresh-up water is chilled or combined with food-grade sanitizers such as chlorine or ozone, in safe and controlled concentrations, to enhance its effectiveness in reducing microbial loads.

Because seafood is extremely prone to bacterial growth, the freshness and safety of fish can be compromised if untreated or contaminated water is used. This is why international guidelines emphasize that only potable water should come into direct contact with fish products.

Fresh-Up Water in HACCP Systems

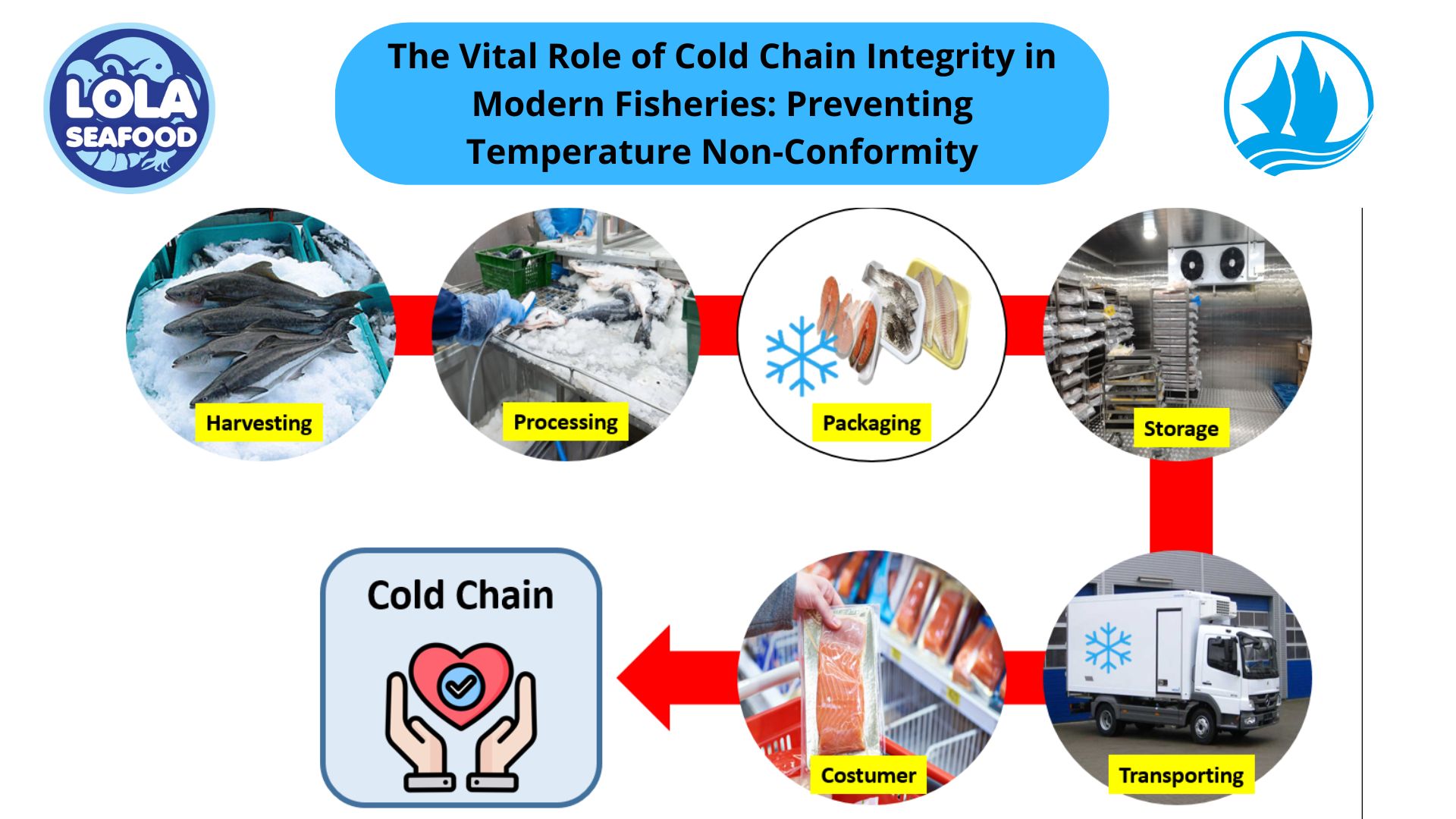

The HACCP framework requires processors to identify potential hazards and establish critical control points to prevent contamination. Water use is one of these critical points. Poor-quality water can introduce biological hazards such as bacteria, chemical hazards like heavy metals, or physical hazards such as sediment or rust particles.

1. Preventing Biological Hazards

Fresh-up water is vital in reducing microbial populations on fish surfaces. By washing off slime, blood, and residues, it prevents bacteria such as Listeria monocytogenes, Vibrio spp., and Salmonella from multiplying. When water is chilled (0–4°C), it also slows bacterial growth and extends product shelf life.

2. Controlling Chemical Hazards

Water must be free of harmful substances such as pesticides, excess chlorine by-products, or heavy metals like lead and mercury. Only food-grade sanitizers are permitted, and their concentrations must be carefully monitored. This ensures that water does not leave harmful residues on the fish.

3. Minimizing Physical Hazards

Particles, rust, or dirt in untreated water may be transferred into the product, affecting both safety and consumer perception. Effective filtration and regular monitoring prevent such risks.

Applications of Fresh-Up Water in Seafood Processing

Fresh-up water is used across multiple stages in fish processing, each with a distinct role:

- Initial Washing

Immediately after unloading, fish are rinsed with fresh-up water to remove blood, scales, slime, and debris. This first wash is essential for slowing spoilage. - Filleting and Cutting Lines

During filleting, water is used to rinse surfaces and remove fragments of bones, flesh, and tissue. Clean water prevents contamination between batches. - Glazing and Freezing

When fish are frozen, a thin layer of fresh-up water is applied to form protective glazing. This prevents freezer burn and acts as a microbial barrier. - Packaging Stage

Before sealing, products are often rinsed again with fresh-up water to ensure no contaminants remain. - Equipment Cleaning

Fresh-up water is not only for the product but also for conveyors, knives, and cutting boards, ensuring hygiene throughout the plant.

International Standards for Water Use

For seafood to be accepted in global markets, water quality management must align with international guidelines.

- Codex Alimentarius requires the use of potable water in all direct food-contact applications.

- European Union Regulations set strict microbiological and chemical thresholds for processing water.

- US FDA and HACCP guidelines demand continuous monitoring of water used in processing, with records kept for audits.

- Indonesia’s SNI (Standar Nasional Indonesia) establishes parameters for potable water in fish processing plants, including microbial limits.

By following these standards, seafood companies not only protect consumer health but also strengthen their position in international trade.

Best Practices in Fresh-Up Water Management

1. Routine Monitoring

Water should be tested regularly for microbial and chemical quality. Results must be documented for verification.

2. Chilling and Sanitation

Using chilled water (0–4°C) helps preserve freshness, while safe doses of chlorine or ozone suppress microbial growth.

3. Maintenance of Infrastructure

Tanks, pipelines, and storage facilities must be cleaned regularly to prevent biofilm buildup.

4. Staff Training

Workers must be trained to understand the importance of using only approved fresh-up water and to avoid shortcuts.

5. Documentation and Auditing

Keeping detailed logs of water testing and usage helps plants demonstrate compliance during HACCP or export audits.

Case Example: Europe and Japan

In Europe, seafood exporters are required to show proof of potable water use in every stage of processing. Regular third-party audits are carried out, and failure to comply can lead to export bans. Similarly, in Japan’s seafood industry, fresh-up water is often chilled seawater that has been filtered and disinfected, balancing both freshness and safety. These examples show how critical water management is to ensuring competitiveness in international seafood trade.

Fresh-up water is far more than just a washing aid; it is a cornerstone of seafood safety and quality assurance. By ensuring that water used in processing is clean, potable, and carefully monitored, seafood companies can minimize hazards, comply with HACCP, and meet international standards. Ultimately, proper fresh-up water practices are an investment in consumer health, brand reputation, and access to global markets.

As the demand for high-quality, safe seafood continues to rise, companies that prioritize water management will not only reduce risks but also gain a stronger edge in the competitive international seafood industry.

If you are interested in our Emperor Grass Whole Round / Whole Gilled Gutted Scaled, Emperor Whole Round / Whole Gilled Gutted Scaled, Emperor Fillet Skin On and Emperor Fillet Skin Less please do not hesitate to contact us through email and/or whatsap

The Dominance of Demersal Fish: The Strategic Export Potential of Indonesia’s Grouper and Parrotfish

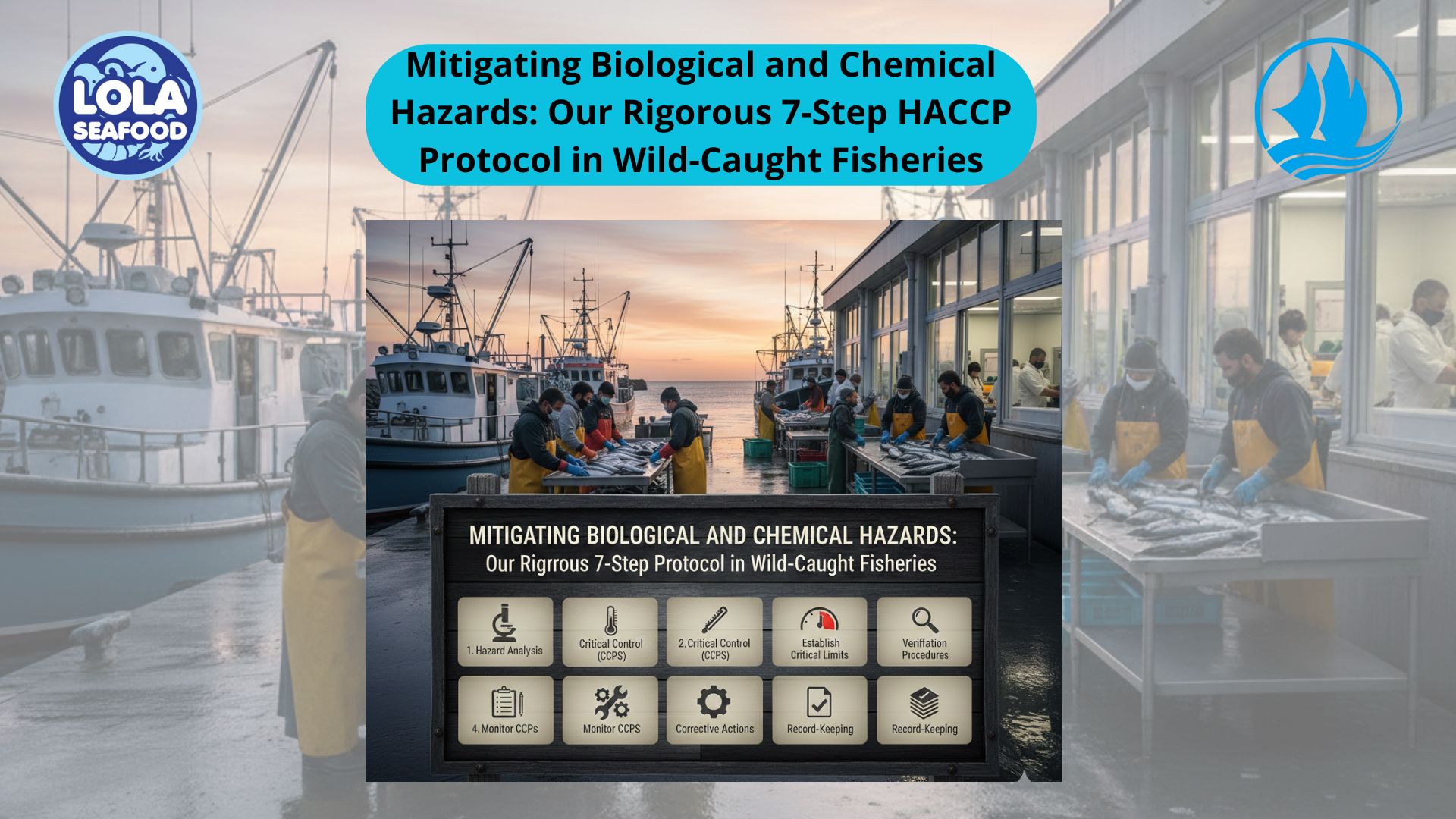

Mitigating Biological and Chemical Hazards: Our Rigorous 7-Step HACCP Protocol in Wild-Caught Fisheries

.jpg)