Challenges in Implementing Good Manufacturing Practices (GMP) in Fisheries Sector

By. Najih - 02 Sep 2025.jpg)

Kelolalaut.com The fisheries industry is a vital part of the global food system, providing fresh and frozen seafood to meet rising consumer demand. However, seafood is among the most perishable food products, making Good Manufacturing Practices (GMP) essential to ensure safety, quality, and compliance with national and international standards. While the benefits of GMP—such as consumer protection, improved quality, and stronger market access—are widely recognized, many fisheries businesses face significant obstacles in implementing these practices effectively. Below are four key challenges commonly encountered in the fisheries sector when applying GMP principles.

1. High Investment Costs in Facility Upgrades and Equipment

One of the greatest barriers for fisheries businesses, especially small and medium enterprises (SMEs), is the financial cost associated with upgrading facilities and equipment to meet GMP standards.

GMP requires facilities to be designed in ways that minimize contamination risks. This may involve installing proper drainage systems, upgrading cold storage, purchasing stainless-steel processing tables, or acquiring advanced monitoring devices for temperature control. For many businesses, these upgrades represent a substantial investment that may not be immediately affordable.

In addition, maintaining equipment to GMP standards requires regular servicing and replacement of parts, which adds to operational costs. While larger companies may have the resources to absorb these expenses, smaller fisheries businesses often struggle to balance short-term financial pressures with long-term safety investments.

2. Need for Continuous Employee Training and Supervision

Another major challenge lies in human resources. GMP is not only about facilities and equipment—it depends heavily on the people involved in daily operations. Employees must follow strict hygiene practices, such as wearing protective clothing, washing hands regularly, and handling seafood with care to prevent contamination.

This requires continuous training and retraining, particularly in fisheries businesses where staff turnover may be high or where seasonal workers are employed. Supervisors must also consistently monitor and enforce compliance. Without strong supervision, even minor lapses—like forgetting to sanitize equipment or mishandling frozen fish—can compromise food safety.

Moreover, training programs can be costly and time-consuming. They require not only financial resources but also a cultural shift within the organization, where food safety becomes a shared responsibility at every level.

3. Resistance to Change in Long-Standing Work Habits

Fisheries businesses often have deep-rooted traditions and established ways of working, especially those that have operated for decades. Introducing GMP can disrupt these practices, leading to resistance from workers or even management. For example, workers accustomed to informal handling of fish might resist wearing gloves or following strict sanitation schedules. Similarly, managers who are used to prioritizing speed and volume over safety may find it difficult to adopt new systems that require additional steps or checks. Overcoming this resistance requires more than just rules and enforcement—it demands effective communication about the benefits of GMP, such as better product quality, improved market access, and consumer safety. Building awareness and a safety-first culture is essential, but this transformation takes time and consistent effort.

4. Maintaining Detailed Records and Documentation

Record keeping is a cornerstone of GMP, ensuring that every stage of production is monitored, verified, and traceable. Fisheries businesses are expected to document everything—from raw material inspections and cleaning schedules to employee training logs and equipment maintenance. For many small businesses, this level of documentation can feel overwhelming. Paper-based systems are often prone to errors, misplacement, or incomplete records. Transitioning to digital record keeping can improve efficiency, but it requires investment in technology and training. Moreover, maintaining accurate and up-to-date records demands discipline and attention to detail. If neglected, poor documentation can lead to regulatory penalties, loss of certifications, or rejection of products in international markets.

If youre interested in our Cobia Whole Round / Whole Gilled Gutted , Cobia Fillet Skinless and Cobia Fillet Skin On please do not hesitate to contact us through email and/or Whatsapp

The Dominance of Demersal Fish: The Strategic Export Potential of Indonesia’s Grouper and Parrotfish

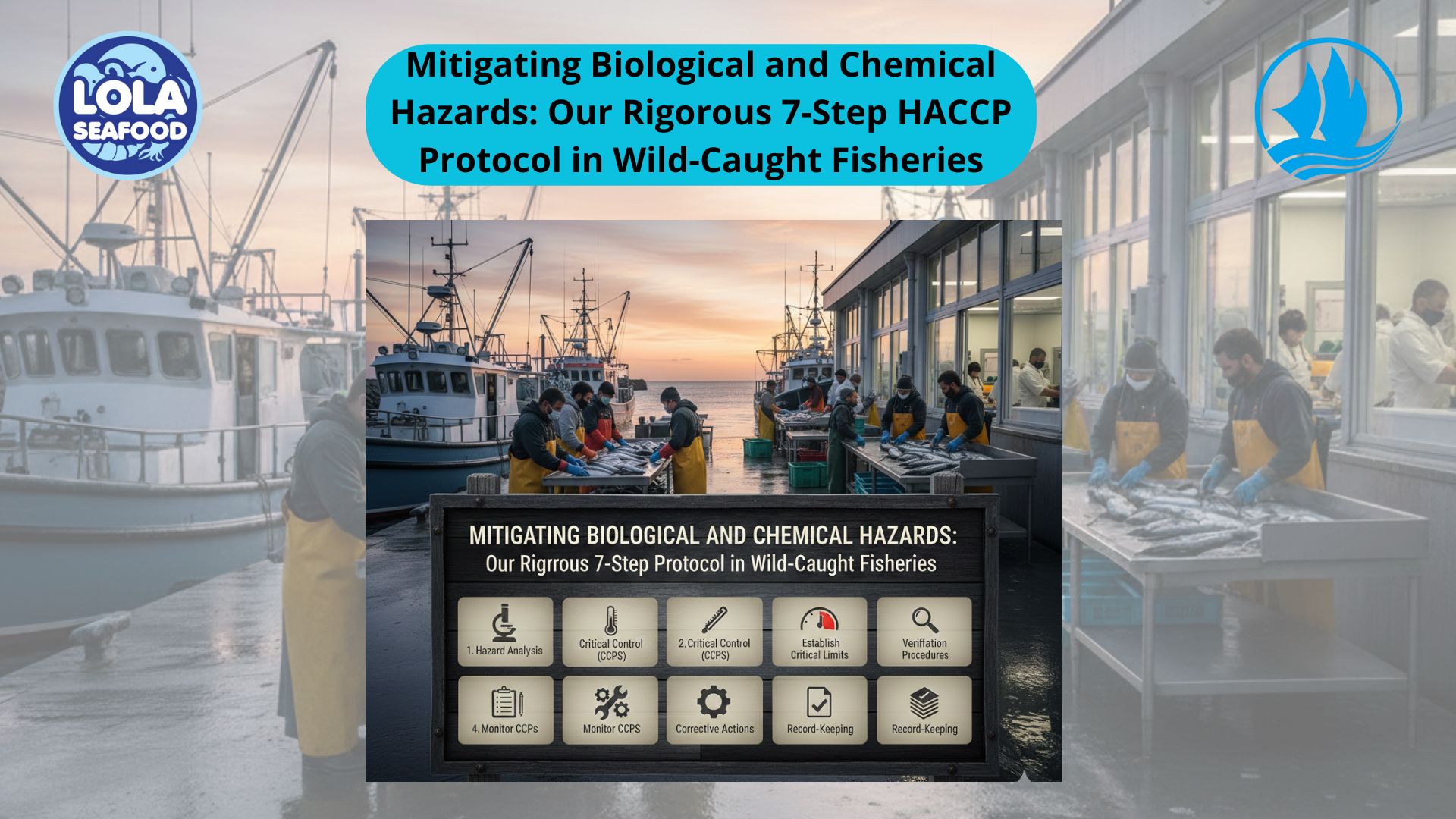

Mitigating Biological and Chemical Hazards: Our Rigorous 7-Step HACCP Protocol in Wild-Caught Fisheries

.jpg)