Understanding Bacterial Contamination in Fish Processing

By. Puji Widyastuti - 02 Sep 2025.jpg)

Kelolalaut.com Bacteria are naturally present in aquatic environments and can easily attach to fish surfaces during capture, transportation, or processing. While some bacteria are harmless, pathogenic bacteria pose a direct risk to consumer health and product quality. Cross contamination—where bacteria spread from one surface, product, or worker to another—is the most common way harmful microorganisms compromise seafood safety.

Common bacteria associated with fish processing contamination include:

1. Salmonella spp. – Often linked to poor hygiene and contaminated water, Salmonella causes severe foodborne illness.

2. Listeria monocytogenes – Known for its ability to grow even at refrigeration temperatures, Listeria is a major concern in ready-to-eat fish products.

3. Vibrio parahaemolyticus and Vibrio vulnificus – Marine bacteria that thrive in warm environments, posing high risks when fish is consumed raw or undercooked.

4. Escherichia coli (E. coli) – An indicator of fecal contamination, suggesting poor handling practices or unsanitary equipment.

These pathogens not only cause illness but also damage consumer trust and may lead to recalls or export rejections.

Key Sources of Cross Contamination

To prevent bacterial risks, it is vital to identify where contamination typically occurs in the fish production chain:

- Raw material handling – Contact between freshly caught fish and contaminated surfaces can transfer bacteria.

- Processing equipment – Knives, cutting boards, conveyor belts, and packaging machines may become bacterial reservoirs if not sanitized.

- Workers’ hygiene – Hands, clothing, or gloves that are not cleaned properly can easily spread bacteria from one fish batch to another.

- Water and ice – If the water or ice used for washing, chilling, or storage is contaminated, it becomes a direct vehicle for bacteria.

- Cross contact between raw and cooked fish – Without strict separation, bacteria from raw fish can reach finished products.

Prevention Strategies: Keeping Fish Safe

To protect seafood safety, every step in processing must focus on preventing bacterial cross contamination. The following strategies are widely recommended in the fish industry:

1. Strict Hygiene and Sanitation Practices

- Regularly clean and disinfect all equipment, surfaces, and tools.

- Use approved sanitizing agents such as chlorine or peracetic acid solutions.

- Implement cleaning schedules and monitor effectiveness with microbiological swabs.

2. Personal Hygiene of Workers

- Enforce handwashing before handling fish and after breaks.

- Provide clean protective clothing, gloves, and hairnets.

- Train workers continuously about food safety and cross-contamination risks.

3. Segregation of Processing Areas

- Separate raw fish areas from cooked or ready-to-eat sections.

- Use color-coded utensils and cutting boards to avoid mixing.

- Design workflow to minimize backtracking and reduce contamination chances.

4. Safe Use of Water and Ice

- Ensure all water and ice come from microbiologically safe sources.

- Regularly test water quality to prevent contamination.

- Store ice in clean, covered containers to avoid exposure to bacteria.

5. Temperature Control

- Keep raw fish at temperatures below 4°C to slow bacterial growth.

- Apply freezing or rapid chilling for longer storage.

- Cook fish products to at least 63°C to eliminate harmful bacteria.

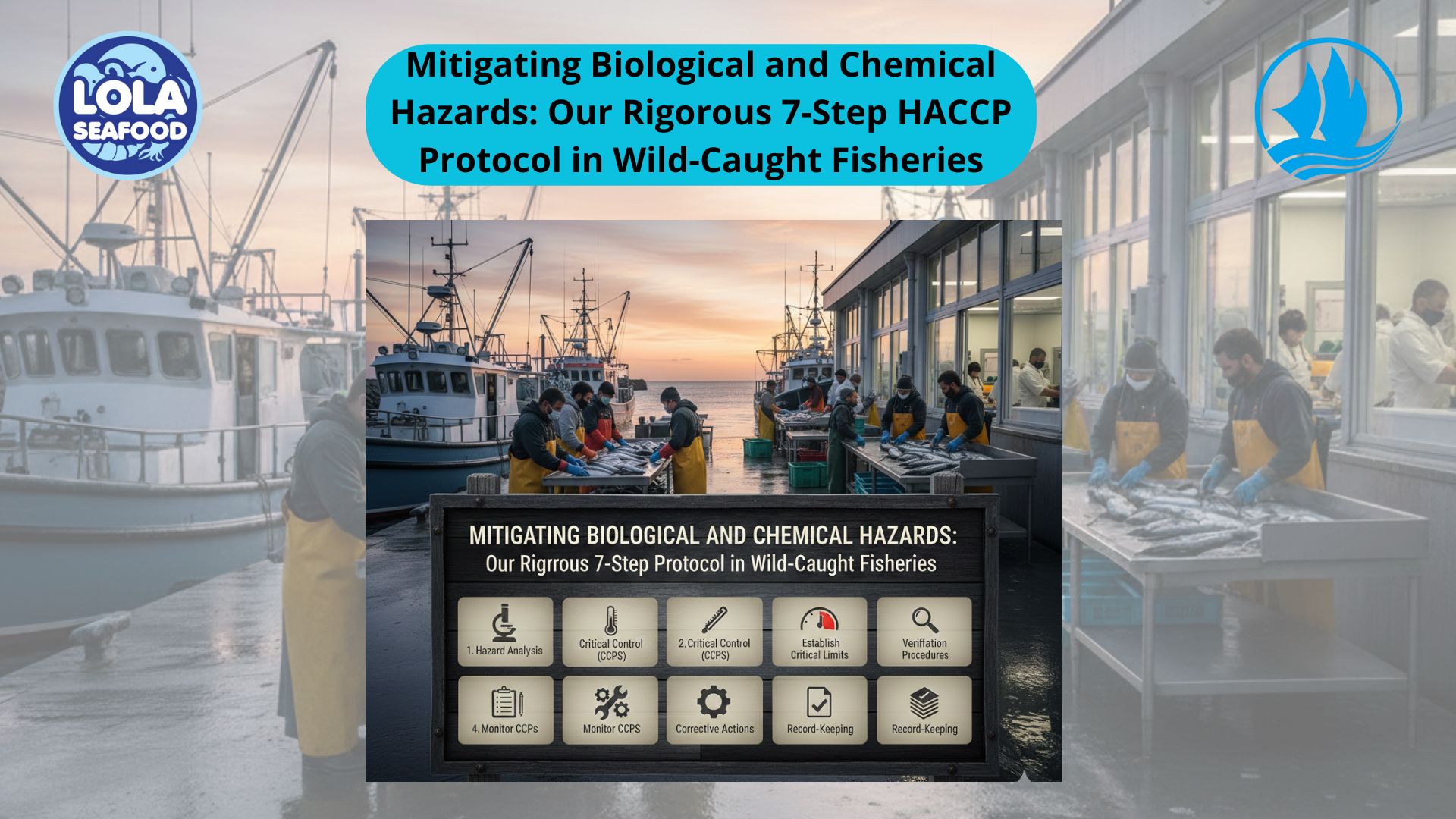

6. Adopting HACCP Systems

Hazard Analysis and Critical Control Points (HACCP) is a systematic approach that identifies contamination risks and sets preventive measures at critical points. Implementing HACCP in fish processing plants ensures continuous monitoring and reduces bacterial hazards effectively.

Building Consumer Trust Through Food Safety

Preventing bacterial contamination in fish processing is not just about compliance with regulations—it is also about protecting public health and strengthening consumer trust. When buyers and international markets recognize that a company maintains strict hygiene and safety standards, it enhances reputation and competitiveness.

Safe seafood means healthier consumers, fewer recalls, and stronger industry growth. By identifying bacterial risks and applying preventive measures, the fish processing sector can ensure high-quality, safe products that meet global standards.

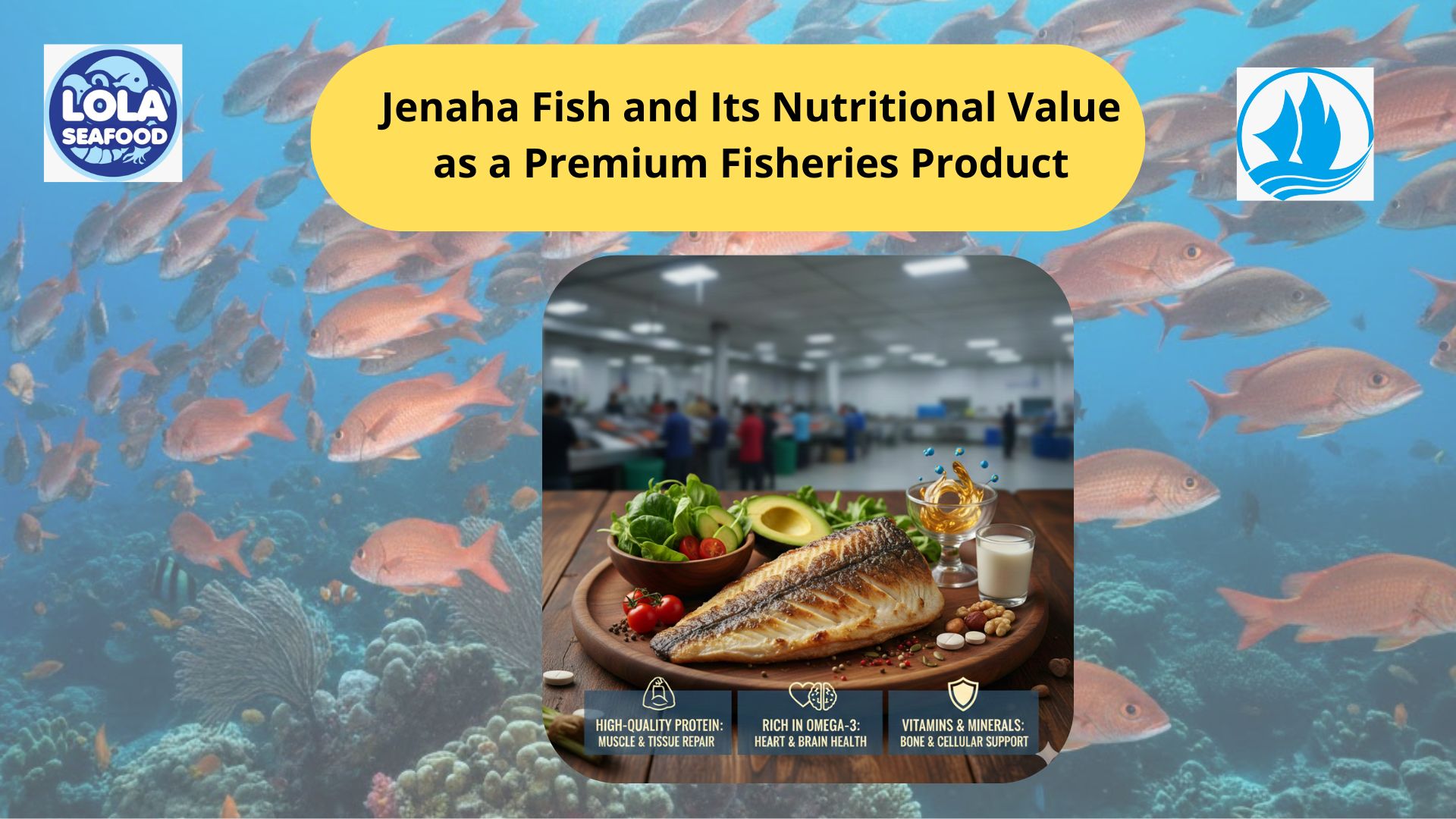

If youre interested in our Red / Scarlet Snapper Indonesian Seaperch Whole Round / Whole Gilled Gutted Scaled , Red / Scarlet Snapper Fillet Skin On and Red / Scarlet Snapper Fillet Portion please do not hesitate to contact us through email and/or whatsapp

The Dominance of Demersal Fish: The Strategic Export Potential of Indonesia’s Grouper and Parrotfish

.jpg)