Building Trust Through World-Class Seafood Processing Standards

By. Lutfi - 15 Jan 2026

kelolalaut.com The global seafood industry is a complex web connecting remote fishing vessels and coastal aquaculture farms to dinner tables thousands of miles away. As seafood consumption continues to rise globally, the journey from "ocean to plate" has come under intense scrutiny. For modern consumers, a delicious meal is no longer enough; they demand assurance that their food is safe, ethically sourced, and processed under the highest possible standards. Building trust in this industry isn't just a marketing goal—itu is a rigorous operational requirement built on world-class processing standards.

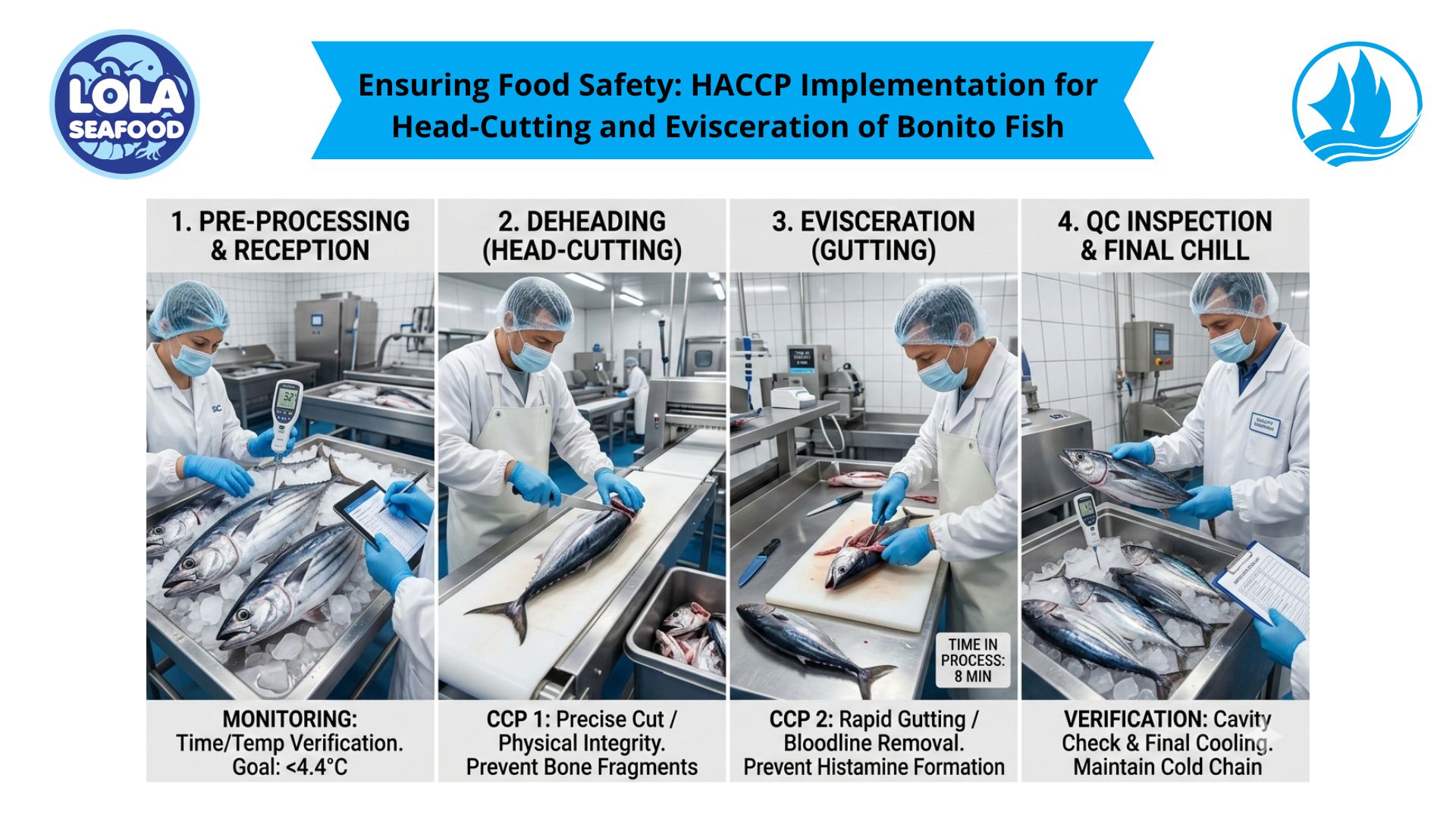

The Foundation of Safety: HACCP and Beyond

At the heart of world-class seafood processing is the Hazard Analysis and Critical Control Point (HACCP) system. This preventative approach to food safety identifies potential biological, chemical, and physical hazards at every stage of production.

However, "world-class" facilities go beyond the legal minimum. They implement comprehensive Global Food Safety Initiative (GFSI) recognized schemes, such as BRCGS (British Retail Consortium Global Standards) or IFS (International Featured Standards). These frameworks ensure:

- Temperature Integrity: Continuous monitoring of the cold chain to prevent bacterial growth.

- Contamination Control: Strict physical separation between "high-risk" (cooked) and "low-risk" (raw) areas.

- Rigorous Testing: Regular microbiological and chemical testing of both the product and the environment.

When a processing plant adheres to these elite standards, it sends a clear message to retailers and consumers: the integrity of the product is non-negotiable.

Transparency Through Traceability

Trust is born from transparency. In the seafood sector, traceability is the ability to track a product through all stages of the supply chain. World-class processors utilize digital ledger technologies and RFID tagging to ensure that every fillet or shrimp can be traced back to a specific vessel, catch date, and even the specific area of the ocean.

This transparency serves two purposes. First, it acts as a safety net; if a quality issue arises, a processor can pinpoint the source and isolate the affected batch within minutes rather than days. Second, it combats the growing problem of seafood fraud—where cheaper species are mislabeled as premium ones. By providing a "digital birth certificate" for seafood, processors build an unbreakable bond of honesty with their customers.

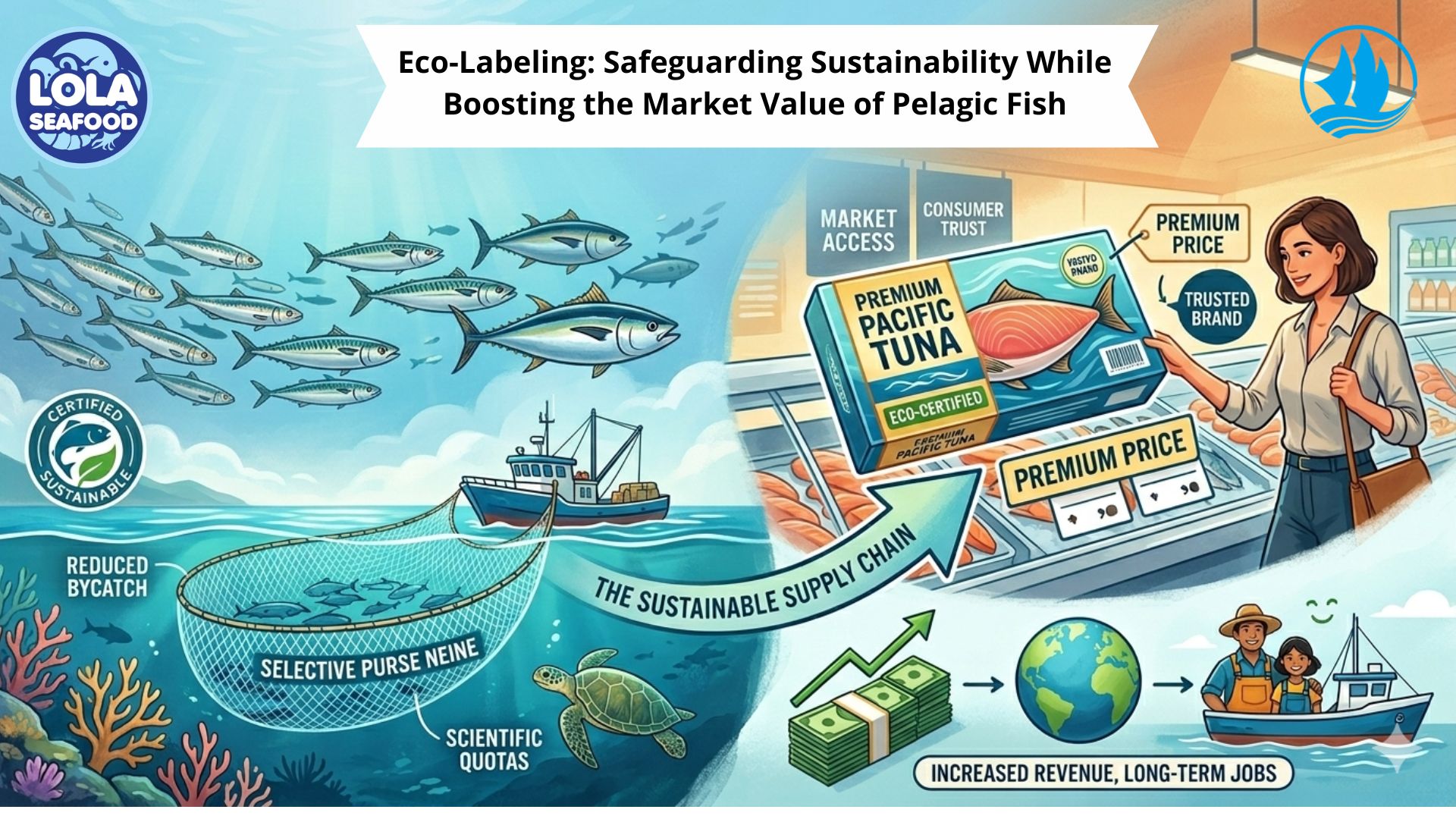

Sustainability and Ethical Sourcing

In 2026, world-class processing isn't just about how the fish is handled inside the factory; it’s about how it was harvested outside of it. Trust is deeply tied to the health of our oceans. Top-tier processors prioritize partnerships with fisheries certified by the Marine Stewardship Council (MSC) or aquaculture farms certified by the Aquaculture Stewardship Council (ASC).

Furthermore, social responsibility has become a pillar of industry standards. Leading processors undergo third-party audits (like SMETA) to ensure fair wages, safe working conditions, and the absence of forced labor. When a processing facility commits to ethical human rights standards, they protect not only the workers but also the reputation of the brands they supply. Trust is destroyed when a product is tainted by environmental destruction or human exploitation; world-class standards provide the shield against these risks.

Innovation: The Role of Technology

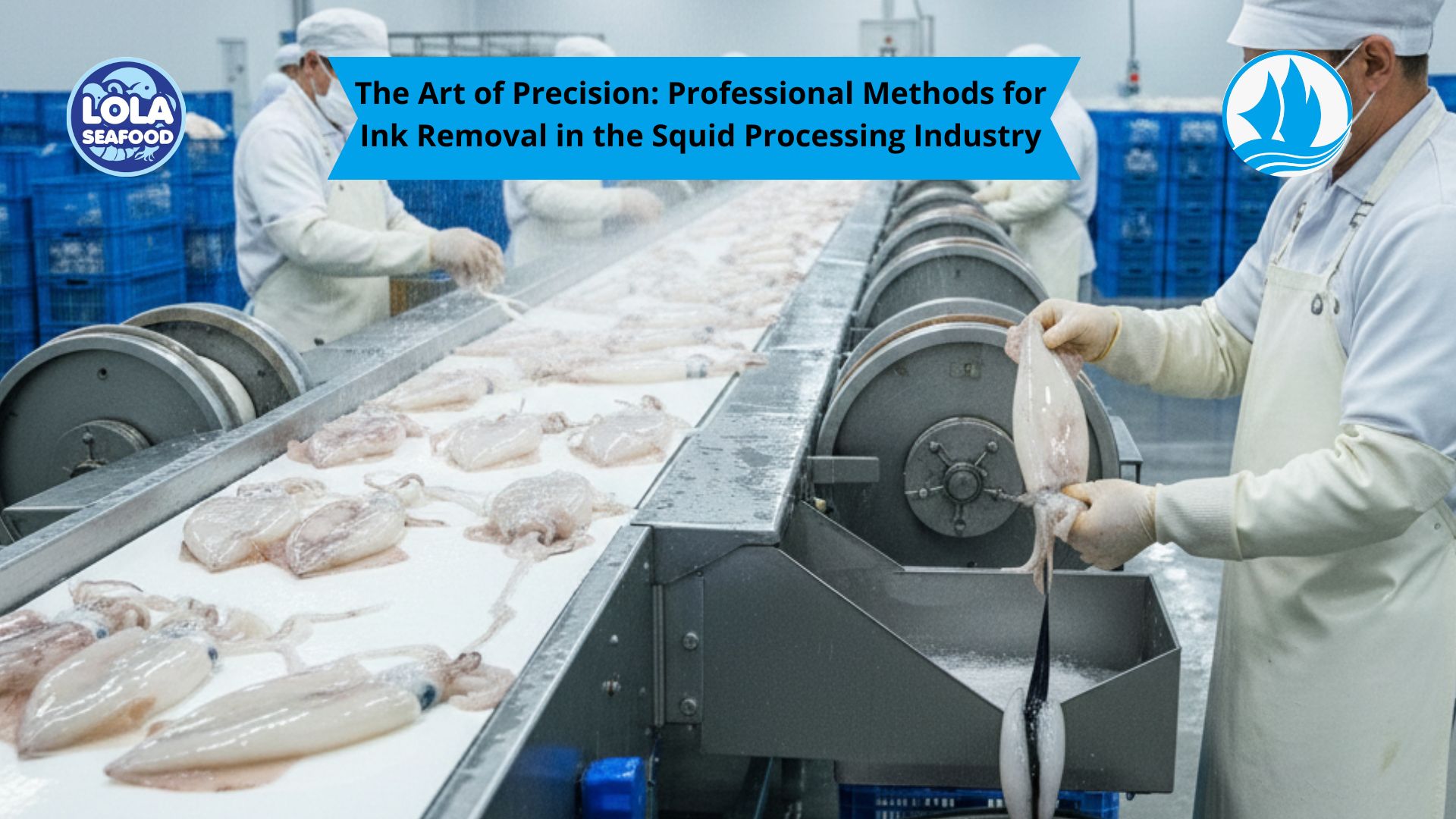

The "world-class" designation is increasingly defined by technological investment. Automation in seafood processing—such as robotic filleting, AI-driven quality inspection, and vacuum-sealing technology—minimizes human contact, thereby reducing the risk of cross-contamination.

Moreover, advanced preservation techniques like Individual Quick Freezing (IQF) and Modified Atmosphere Packaging (MAP) allow processors to lock in the "just-caught" freshness and nutritional value without the need for chemical preservatives. These innovations allow the consumer to enjoy a premium experience, reinforcing the belief that the processor is utilizing the best tools available to protect the consumer's health.

Why Standards Matter for the Future

The seafood industry faces significant challenges, from climate change affecting fish stocks to the increasing complexity of international trade. In this volatile environment, standardization is the language of reliability. For a processor, achieving world-class certification is an expensive and grueling process. It requires constant training, infrastructure upgrades, and a culture of "continuous improvement." However, the return on investment is the most valuable currency in the modern economy: consumer confidence.

When a consumer sees a certification mark on a package, they aren't just looking at a logo. They are looking at a promise. They are trusting that the processor has done the hard work of vetting the source, maintaining the cold chain, and ensuring the highest level of hygiene.