The Vital Role of Cold Chain Integrity in Modern Fisheries: Preventing Temperature Non-Conformity

By. Puji Widyastuti - 24 Dec 2025

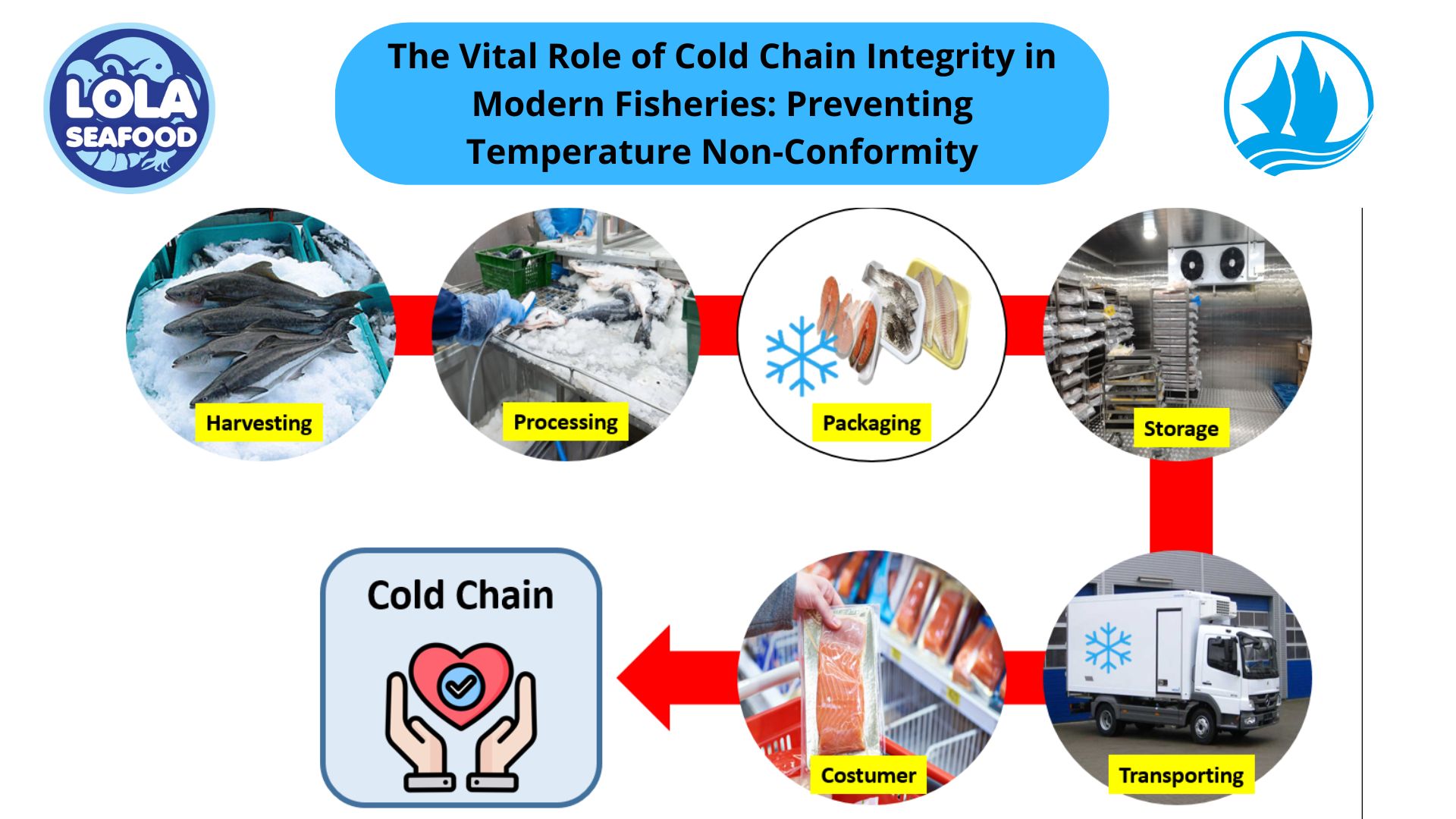

kelolalaut.com The global fishing industry is a race against time and biology. From the moment a fish is hauled from the depths of the ocean onto the deck of a vessel, a countdown begins. The single most critical factor in winning this race is the Cold Chain. Maintaining a seamless, temperature-controlled environment from "hook to fork" is not just a logistical preference; it is a biological necessity. In the processing of wild-caught fish, preventing temperature non-conformity is the primary defense against spoilage, economic loss, and public health crises.

Understanding the Vulnerability of Seafood

Fish are uniquely perishable. Unlike land-based livestock, fish possess high water content, neutral pH levels, and a high proportion of unsaturated fats. Furthermore, the enzymes and bacteria present in fish are adapted to cold aquatic environments, meaning they remain active even at refrigerator temperatures.

When temperature non-conformity occurs—meaning the product deviates from the required chilled or frozen range—three destructive processes accelerate:

- Microbial Proliferation: Bacteria such as Pseudomonas and Vibrio multiply exponentially in warm conditions, leading to rapid decay.

- Enzymatic Degradation (Autolysis): Natural enzymes in the fish’s gut and muscle begin to break down the flesh, turning it soft and unappealing.

- Chemical Oxidation: Fats in fish react with oxygen more quickly at higher temperatures, causing rancidity and off-flavors.

The Domino Effect: Stages of the Cold Chain

Maintaining the cold chain is a continuous effort. If a single link breaks, the quality of the fish is permanently compromised, regardless of how well it is cooled later.

1. Immediate Post-Capture Cooling

The clock starts on the vessel. Techniques such as Slush Ice or Refrigerated Sea Water (RSW) systems are vital. Rapidly lowering the core temperature of the fish to near 0°C (32°F) immediately after death slows down rigor mortis and inhibits the initial burst of bacterial growth.

2. Processing and Handling

During the processing stage—filleting, skinning, and packaging—the fish is often exposed to ambient air. This is the most "high-risk" zone for temperature non-conformity. Processing facilities must be climate-controlled, and the time fish spends on the "dry" line must be minimized. Workers must be trained to recognize that even 15 minutes of exposure to 20°C can significantly reduce the shelf life of a high-value tuna or salmon.

3. Storage and Transportation

Whether the fish is chilled (fresh) or blast-frozen, the storage environment must be stable. Fluctuating temperatures during transit can cause "thaw-refreeze" cycles. In frozen products, this leads to the formation of large ice crystals that puncture cell membranes, resulting in moisture loss (drip loss) and a "woody" texture when the fish is eventually cooked.

The Hidden Danger: Histamine Formation

One of the most dangerous consequences of temperature non-conformity is Scombroid Poisoning. Certain species, such as tuna, mackerel, and mahi-mahi, contain high levels of the amino acid histidine. When these fish are kept at temperatures above 4°C (40°F), specific bacteria convert histidine into histamine.

Unlike many other toxins, histamine is heat-stable—meaning once it is formed, cooking or canning will not remove it. For processing plants, preventing temperature spikes is the only way to ensure consumer safety and avoid costly product recalls.

Economic and Sustainability Implications

The importance of the cold chain extends beyond safety; it is a matter of economic survival and environmental ethics.

- Reducing Food Waste: Roughly 35% of global fish and seafood harvest is lost or wasted, much of it due to poor temperature management. In a world with a growing population, wasting protein is an ecological failure.

- Market Access: International markets, particularly the EU and the US, have stringent HACCP (Hazard Analysis and Critical Control Points) regulations. Failure to document a continuous cold chain can result in entire shipments being rejected at the border, leading to massive financial losses for fishers and exporters.

- Premium Pricing: Fish maintained at a perfect, stable temperature retains its color, texture, and nutritional value, allowing producers to command higher "sushi-grade" or "premium fresh" prices.