Understanding Modern IPAL: Ensuring Production Wastewater is Clearer Before Returning to Nature

By. Nugroho Luhur - 16 Dec 2025

kelolalaut.com The ocean has always been the lifeblood of our coastal communities. For a fish processing company, the sea is not just a source of raw materials; it is a partner in our shared ecosystem. However, we understand that with industrial growth comes a natural concern from the community: "What happens to the water used inside the factory?"

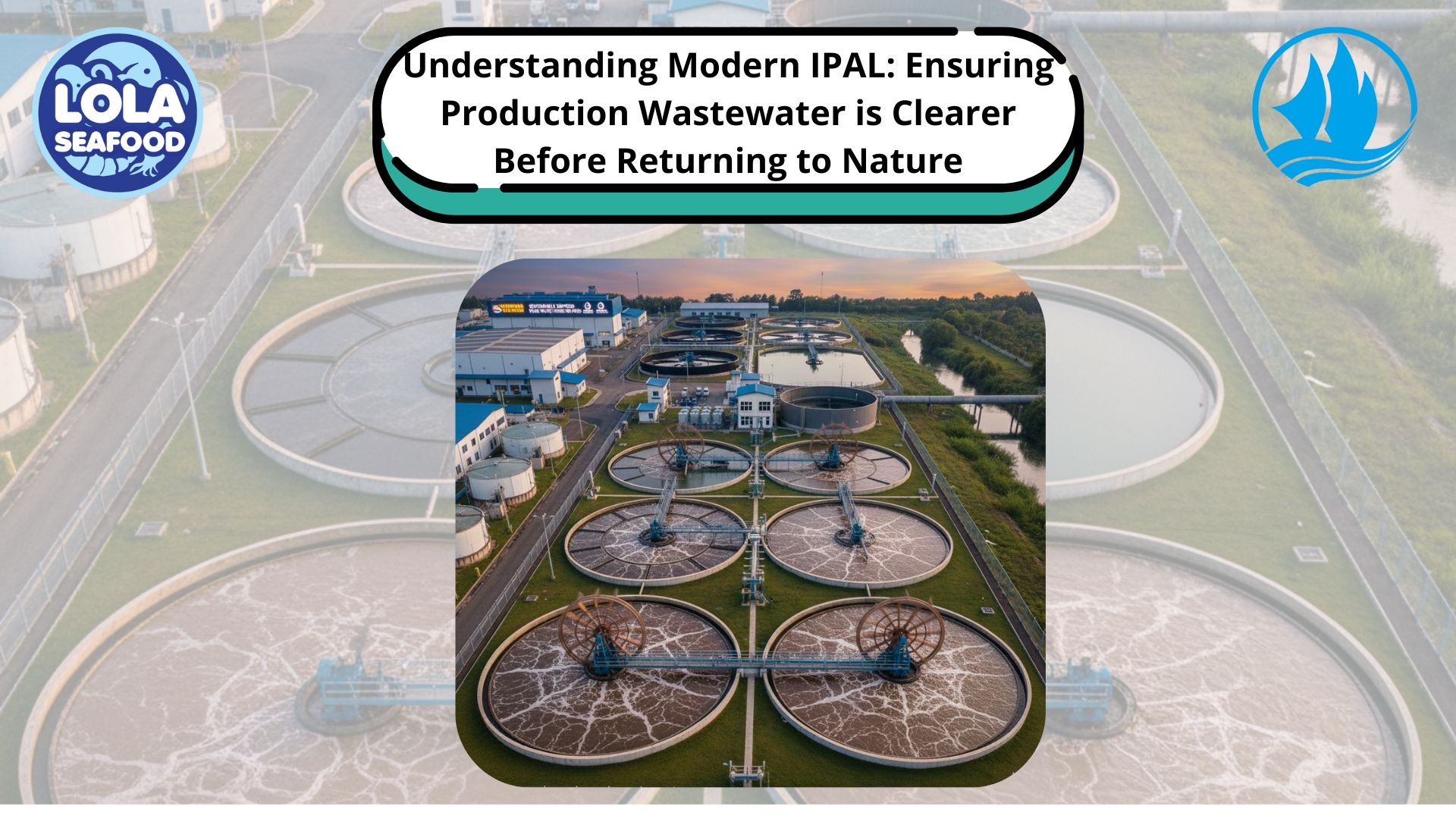

Public anxiety regarding industrial waste is valid. Untreated wastewater from fish processing can contain high levels of organic matter, such as proteins, fats, and oils, which—if released directly—could deplete oxygen in local water bodies and affect aquatic life. To address this, our company has invested in a Modern Wastewater Treatment Plant (known in Indonesia as IPAL - Instalasi Pengolahan Air Limbah). This system ensures that every drop of water used in our facility undergoes a rigorous purification process, often resulting in water that is clearer and safer than the natural sources it returns to.

The Science of Purification: How It Works

Modern wastewater treatment is no longer just about "filtering" water; it is a sophisticated, multi-stage biological and mechanical process. Here is how we transform production effluent into clean water:

1. Physical Pre-treatment: Removing the Basics

The process begins with mechanical screening. Before the water reaches the treatment tanks, we remove solid particles like scales and skin fragments. We also employ Dissolved Air Flotation (DAF) technology. This system introduces tiny air bubbles into the water, causing fats, oils, and grease to float to the surface where they can be skimmed off. By removing these organic solids early, we prevent odors and ensure the subsequent stages can work efficiently.

2. Biological Treatment: Nature’s Own Cleaning Crew

The heart of our modern IPAL is the biological stage. Instead of using harsh chemicals, we harness the power of "good bacteria" or microorganisms. In large, aerated tanks, these microbes "eat" the dissolved organic pollutants. This is a natural process accelerated by technology. We monitor the oxygen levels and microbial health 24/7 to ensure these tiny workers are effectively breaking down any remaining fish proteins or nutrients.

3. Advanced Filtration and Clarification

Once the microbes have done their job, the water moves to a clarification tank where the biological mass settles at the bottom, leaving clear water at the top. To ensure the highest quality, our modern system uses Ultra-Filtration (UF) or Membrane technologies. These membranes act as microscopic sieves, catching even the smallest impurities that the naked eye cannot see.

Transparency Through Real-Time Monitoring

One of the key differences between a "traditional" factory and a "modern" eco-friendly facility is transparency. Our modern IPAL system is equipped with digital sensors that measure critical water quality parameters, such as:

- pH Levels: Ensuring the water is neither too acidic nor too alkaline.

- TSS (Total Suspended Solids): Measuring the clarity of the water.

- COD and BOD: Ensuring the organic load is well below government-mandated safety limits.

These results are recorded and reported to environmental authorities regularly. By digitizing this data, we eliminate human error and provide a verifiable "green record" that the community can trust.

Beyond Disposal: A Circular Economy Approach

Our commitment to the environment goes beyond just "cleaning" water. In a modern industrial setup, we view waste as a misplaced resource. The organic solids recovered from the DAF system and the biological sludge are often repurposed into organic fertilizers or fish meal, ensuring that nothing goes to waste.

Furthermore, we are moving toward a "Water Recycle" model. A significant portion of the treated water is often clean enough to be reused for non-production purposes, such as facility cleaning or watering the green belts around the factory. This reduces our overall consumption of fresh water, preserving local groundwater for the community’s needs.

A Promise to Our Neighbors

We recognize that a factory does not exist in a vacuum. We are part of your neighborhood, and our employees breathe the same air and fish in the same waters as you do. The implementation of a Modern IPAL system is not just about complying with government regulations; it is about our moral obligation to the next generation.

When you see our facility, we want you to see more than just a place of business. We want you to see a guardian of the environment. Our "clear water" policy is our promise that our industrial activities will never come at the expense of the natural beauty and health of our region.

Conclusion

Modern industry and environmental preservation are not enemies; they are two sides of the same coin. Through the use of advanced IPAL technology, rigorous monitoring, and a culture of transparency, we are proving that fish processing can be clean, odorless, and sustainable. We welcome the community to learn more about our processes, as we believe that knowledge is the best cure for anxiety. Together, we can ensure that our industry prospers while our waters remain blue, clear, and full of life.