Best Sanitation Practices for Fish Processing Plants to Prevent Environmental Contamination

By. Sofie Thoriq - 03 Dec 2025

kelolalaut.com The operation of a fish processing plant presents unique challenges concerning sanitation, not only to ensure food safety and the quality of the final product but also to prevent the discharge of harmful pollutants into the surrounding environment. Fishing is a vital industry, but its associated waste and wastewater, if improperly managed, can severely impact local ecosystems, particularly water bodies. Implementing comprehensive and strict sanitation practices is paramount to achieving sustainable and responsible operations.

Understanding the Waste Streams

Fish processing generates several significant waste streams that require careful management. These include solid waste (fish offal, bones, scales, and spoiled product), and wastewater (from washing, cleaning, and processing activities). The wastewater is particularly problematic as it is high in Organic Loading (measured as BOD and COD), Total Suspended Solids (TSS), fats, oil, and grease (FOG), and pathogens. Without proper treatment, this highly contaminated water depletes oxygen in receiving waters, harming aquatic life and promoting eutrophication.

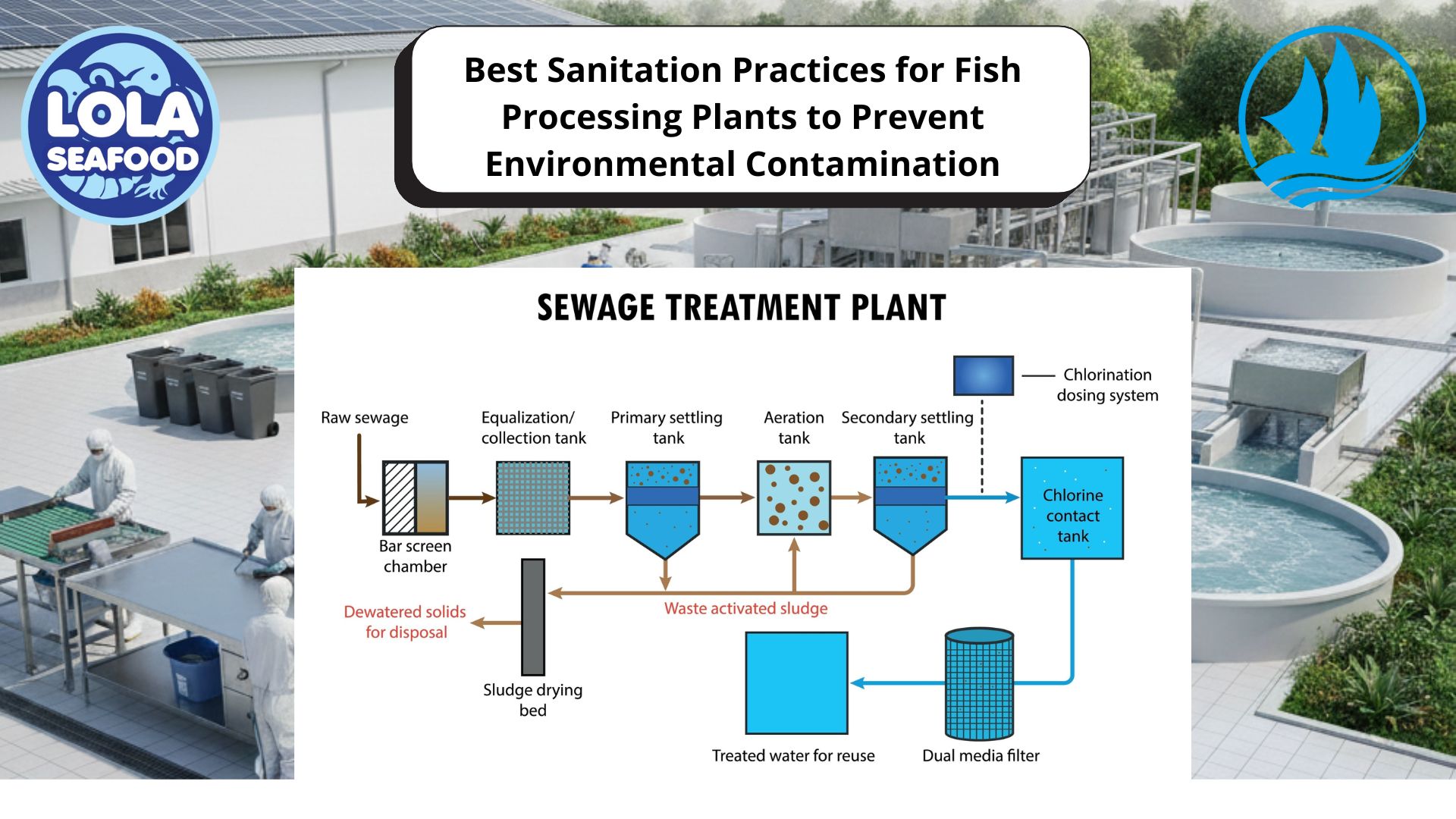

Wastewater Treatment: The Core Strategy

The most critical component of environmental sanitation for a fish processing plant is its Wastewater Treatment Plant (WWTP). A multi-stage approach is typically required to effectively reduce pollutants to an environmentally safe level.

Primary Treatment: Separation

This initial stage focuses on removing large solids and FOG.

- Screens: Industrial screens are essential for removing large particles of fish waste and debris, which are then diverted to solid waste management.

- Dissolved Air Flotation (DAF) or Grease Traps: These systems are highly effective at separating FOG. The DAF unit works by injecting fine air bubbles into the wastewater, causing the lighter FOG particles to float to the surface for skimming.

Secondary Treatment: Biological Degradation

After the initial separation, the remaining wastewater is still rich in dissolved organic matter.

- Aerobic Biological Treatment: This involves using tanks (like activated sludge or sequencing batch reactors) where beneficial bacteria consume the organic matter in the presence of oxygen. This significantly reduces the BOD and COD load.

- Anaerobic Digestion: For plants with high organic loads, anaerobic digestion can be employed, which not only breaks down the organics but can also produce biogas (a renewable energy source).

Tertiary Treatment: Polishing and Disinfection

The final stage ensures the water meets local discharge standards.

- Filtration: Sand filters or membrane bioreactors (MBRs) remove fine suspended solids.

- Disinfection: Methods like UV radiation or chlorination are used to kill any remaining pathogens before the treated effluent is discharged or reused.

Solid Waste Management and Valorization

Solid fish waste (offal) must be kept out of the general wastewater flow to avoid overwhelming the WWTP. Good practices include:

- Source Separation: Implementing clearly marked bins and procedures to separate fish offal immediately upon creation.

- Revalorization (Turning Waste into Value): Instead of disposal, solid waste should be viewed as a resource. Offal can be processed into fishmeal and fish oil for animal feed, pet food, or even nutraceuticals. This practice reduces disposal costs and creates a secondary revenue stream while lessening the environmental burden.

- Composting: Offal can also be composted, often mixed with other organic materials, to create fertilizer.

Plant Hygiene and Process Control

Sanitation practices within the plant directly impact the environmental load of the effluent.

- Dry Cleaning First: Before any wet cleaning, employees should prioritize scraping and sweeping solid debris into designated containers. This simple step drastically reduces the amount of solid material and highly concentrated wash water entering the drains.

- Efficient Water Use: Minimizing water consumption reduces the overall volume of wastewater to be treated. Implementing high-pressure, low-volume spray nozzles and reusing treated water for non-contact applications (like floor washing) are effective strategies.

- Detergent and Chemical Management: Only use approved, biodegradable cleaning agents. Ensure the correct concentrations are used to avoid excessive chemical residues in the wastewater.

Monitoring and Compliance

A good sanitation plan requires consistent oversight. Regular sampling and testing of the effluent is non-negotiable to ensure compliance with environmental regulations. Key parameters to monitor are pH, BOD/COD, TSS, and FOG. Maintaining detailed records of the waste management process demonstrates commitment to environmental stewardship.

By adopting a holistic approach that prioritizes dry cleaning, efficient water use, advanced wastewater treatment, and the valorization of solid waste, fish processing plants can significantly minimize their ecological footprint, ensure product safety, and operate as responsible partners in their communities.