Beyond Measurement: Why Fish Sizing Matters for HACCP Standards

By. Ely Kusniawati - 27 Aug 2025.jpg)

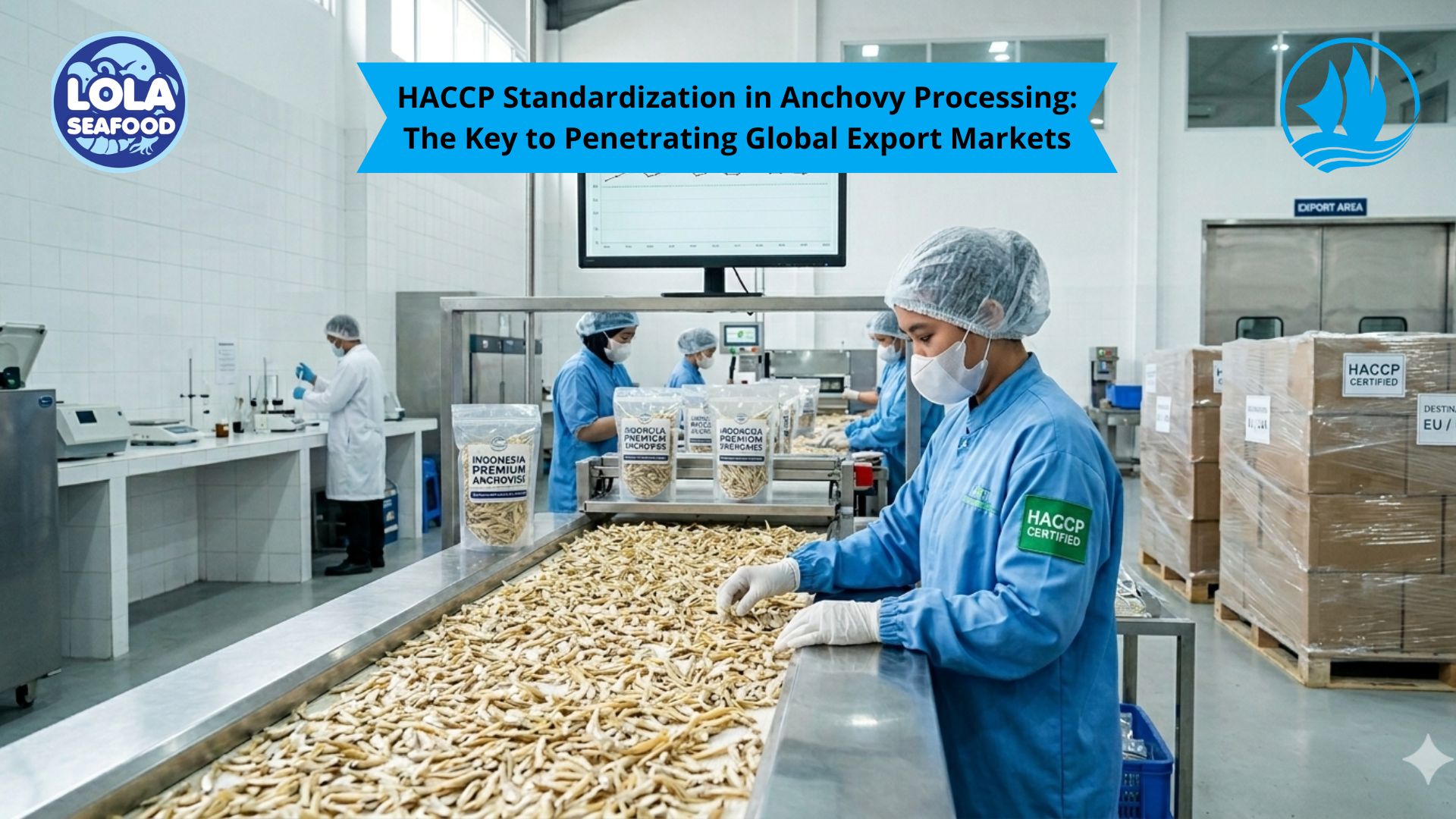

Kelolalaut.com In the seafood processing industry, sizing may seem like a simple step—sorting fish by weight, length, or thickness. However, in the context of Hazard Analysis and Critical Control Points (HACCP), sizing plays a far greater role than just measurement. It is directly linked to food safety, product quality, and compliance with international standards. By ensuring accurate and consistent sizing, processors not only streamline operations but also protect consumers and strengthen global market trust.

Understanding Fish Sizing in Processing

Fish sizing refers to the systematic sorting of fish into uniform categories based on specific parameters such as weight, length, or portion size. This step is often performed using calibrated machines, rollers, or manual techniques, depending on the scale of production. The primary goal is to achieve consistency, which is crucial for further processing steps like filleting, cooking, freezing, or packaging.

In HACCP, sizing can become a Critical Control Point (CCP) because inconsistent or incorrect sizing may lead to uneven processing, which in turn can pose food safety risks. For instance, if fish pieces vary too widely in size, some portions may remain undercooked or improperly frozen, allowing bacteria to survive and potentially reach the consumer.

Why Sizing Matters for HACCP Standards

1. Uniform Cooking and Thermal Processing

Proper sizing ensures that fish portions cook or freeze evenly. HACCP emphasizes controlling time and temperature to prevent microbial growth. If sizes vary, smaller pieces may be overcooked and dry, while larger ones may remain unsafe due to incomplete heat penetration.

2. Consistent Freezing and Storage

Freezing is a critical preservation method in seafood processing. Uniformly sized fish allow for predictable freezing times, reducing the risk of temperature abuse. This minimizes the chance of pathogens such as Listeria monocytogenes or Salmonella surviving in the product.

3. Accurate Packaging and Labeling

Consistency in sizing helps achieve accurate portion control, which is crucial for nutritional labeling, consumer expectations, and regulatory compliance. In HACCP, mislabeling is considered a potential hazard because it can mislead customers and trigger recalls.

4. Preventing Cross-Contamination

During the sizing process, fish come into contact with equipment and utensils. Properly designed and sanitized sizing systems reduce the risk of cross-contamination between batches. HACCP requires monitoring of these critical points to ensure food safety.

5. Supporting Traceability

Sizing contributes to efficient product traceability. When fish are categorized and recorded accurately, it becomes easier to track batches throughout the supply chain. This is vital in case of recalls or investigations into foodborne illness outbreaks.

The Link Between Sizing and Consumer Trust

Consumers may not realize it, but when they see a package of uniformly cut fish fillets at the supermarket, they are experiencing the results of precise sizing practices. This consistency conveys professionalism, safety, and quality. In international markets, especially in regions like the European Union, United States, and Japan, strict HACCP compliance is mandatory for seafood imports. Proper sizing ensures that products meet these standards, reinforcing trust and enabling processors to remain competitive.

Best Practices for HACCP Based Sizing

To maximize the benefits of sizing within HACCP systems, seafood processors should implement the following practices:

- Calibration of Equipment: Regularly check sizing machines to ensure accuracy and consistency.

- Employee Training: Staff must understand the importance of sizing as part of HACCP, not just as a mechanical step.

- Hygienic Design: Use equipment designed to be easily cleaned and resistant to contamination.

- Monitoring Records: Keep detailed records of sizing operations as part of HACCP documentation.

- Integration with CCPs: Identify where sizing influences food safety (e.g., cooking or freezing stages) and set critical limits accordingly.

Fish sizing in seafood processing goes far beyond measurement. It is an essential factor in ensuring compliance with HACCP standards, safeguarding consumers, and maintaining market credibility. By focusing on consistency, hygiene, and proper monitoring, processors can turn sizing into a powerful tool that supports both safety and efficiency.

Ultimately, accurate fish sizing is not just about producing neat portions—it is about protecting lives, building trust, and upholding the reputation of the seafood industry on a global scale.

If youre interested in our Grouper Black Dotted Whole Round , Grouper Fillet Portion Cut and Grouper Fillet Skinless please do not hesitate to contact us through email and/or whatsapp.