Don’t Just Let It Melt! Understanding Defrosting Techniques That Determine Your Fish's Market Value

By. Ely Kusniawati - 05 Feb 2026

In the high-stakes world of the seafood industry, "quality" is the ultimate currency. From the moment a fish is hauled onto a vessel and flash-frozen, a race against biological degradation begins. However, many processors and distributors overlook a critical bridge in the production chain: the defrosting (thawing) process.

While it might seem like a simple matter of raising the temperature, improper thawing can turn a premium-grade tuna or salmon into a mushy, low-value product. In the industry, we often say that while freezing preserves quality, thawing is what actually reveals—or destroys—it.

Why Defrosting is a Make-or-Break Factor

When fish is frozen, the water inside its cells forms ice crystals. If the fish was frozen slowly, these crystals are large and jagged, puncturing cell membranes. If thawed incorrectly, the cellular fluid—rich in proteins, vitamins, and flavor—leaks out. This is known as Drip Loss.

High drip loss leads to two major problems:

- Economic Loss: Fish is sold by weight. If 5% of the weight leaks out as "drip," you are literally watching your profits pour down the drain.

- Quality Degradation: Lost fluids mean the texture becomes dry and fibrous, and the vibrant color of the flesh fades. This significantly lowers the market price.

The Science of the "Danger Zone"

The primary goal of industrial defrosting is to move the product through the thermal arrest period—the temperature range where ice melts—as quickly and evenly as possible without allowing the surface temperature to enter the "Danger Zone" (4°C to 60°C). In this zone, microbial growth accelerates, and histamine levels (especially in species like tuna and mackerel) can spike, posing a safety risk and potentially leading to product rejection by health authorities.

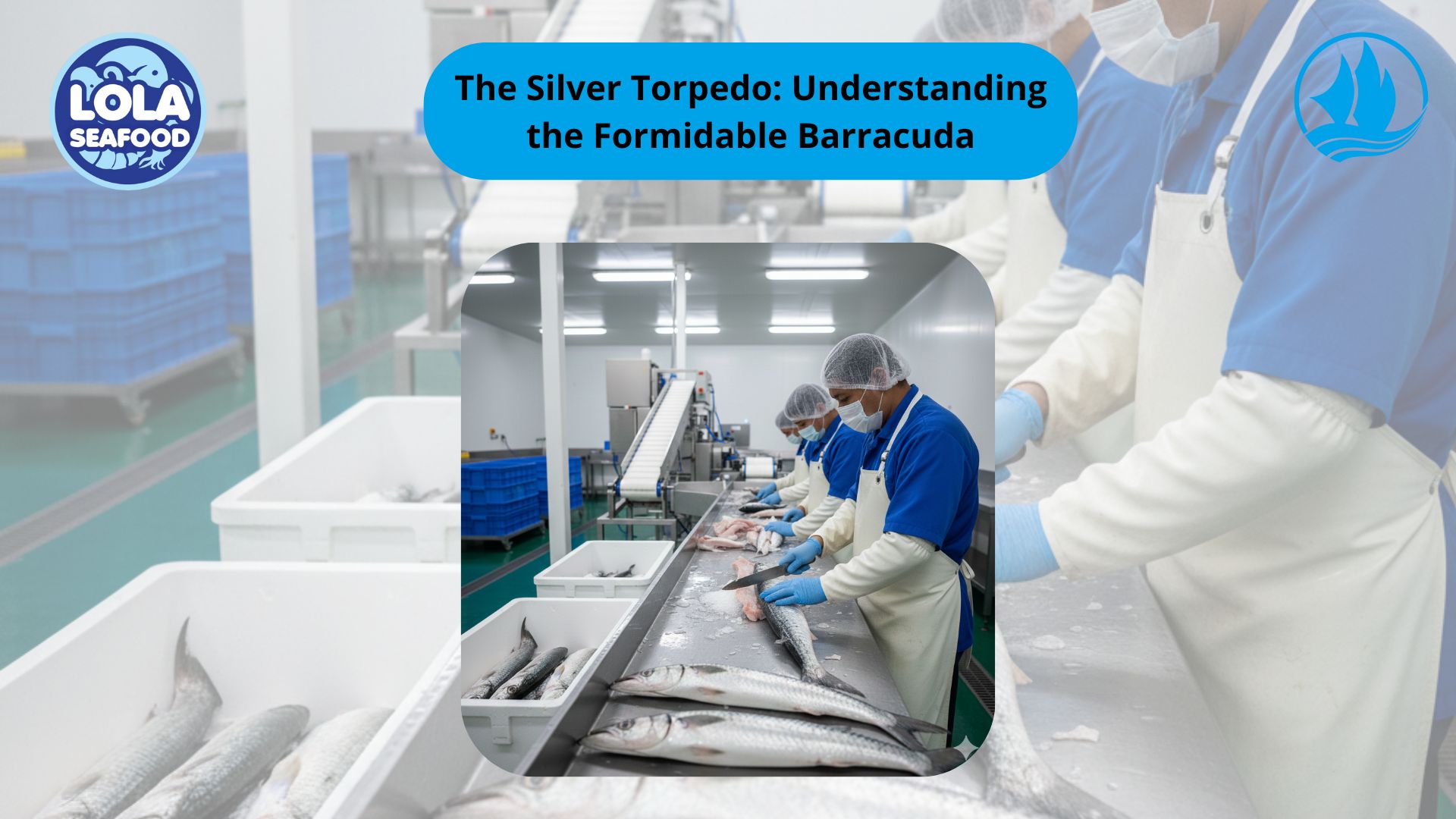

Leading Industrial Defrosting Methods

To maintain "A-Grade" status, the industry utilizes several sophisticated methods, each with its own pros and cons:

1. Air Thawing (Controlled Atmosphere)

This involves placing fish in rooms with controlled humidity and airflow.

- Pros: Low cost and simple setup.

- Cons: Very slow. If humidity isn't high (around 90%), the surface of the fish dries out (evaporation loss), leading to a dull appearance and weight loss.

2. Water Thawing (Immersion or Spray)

Water is a much better conductor of heat than air, making this method faster.

- Pros: Significantly faster than air thawing.

- Cons: Excessive water contact can "wash out" the flavor and color of the fish. Furthermore, if the water isn't properly treated or circulated, it can become a breeding ground for cross-contamination.

3. Acoustic and High-Frequency Thawing

The cutting edge of the industry involves using ultrasonic waves or radio frequencies (RF) to vibrate water molecules within the fish.

- Pros: Incredibly fast and generates heat from the inside out, ensuring the core thaws at the same rate as the surface. Drip loss is kept to an absolute minimum.

- Cons: High initial investment in equipment.

4. Vacuum Thawing

By lowering the atmospheric pressure, steam can be generated at very low temperatures (e.g., 20°C). This latent heat thaws the fish rapidly without "cooking" the exterior.

- Pros: Excellent texture retention and zero surface dehydration.

Impact on Market Value: A Comparison

Consider two batches of the same Yellowfin Tuna.

- Batch A is thawed haphazardly in a warm room. It loses 8% of its weight in drip, the flesh looks "gaped" (separated), and the color is brownish. This fish is relegated to the canning industry or low-tier local markets.

- Batch B is thawed using a controlled vacuum or high-humidity system. Weight loss is under 2%, the flesh remains firm and translucent, and it retains its bright red "sashimi-grade" hue.

The price difference between Batch A and Batch B can be as high as 30–50%. In an industry where margins are often thin, the defrosting method isn't just a technical detail—it is the difference between profit and loss.

If youre interested in our Baby Octopus Flower Black Pomfret Portion Cut, Coral Trout Whole Round, Snapper / Red Bass Whole Round / Whole Gilled Gutted Scaled , Snapper Fillet Skinless and Snapper Mangrove Jack Whole Round / Whole Gilled Gutted Scaled, Barramundi Fillet Skinless please do not hesitate to contact us through email and/or Whatsapp

The Deep-Sea Treasure of High-Quality Protein.jpg)