The Global Evolution of Squid Processing: From Industrial Efficiency to Value-Added Innovation

By. Nugroho Luhur - 22 Dec 2025

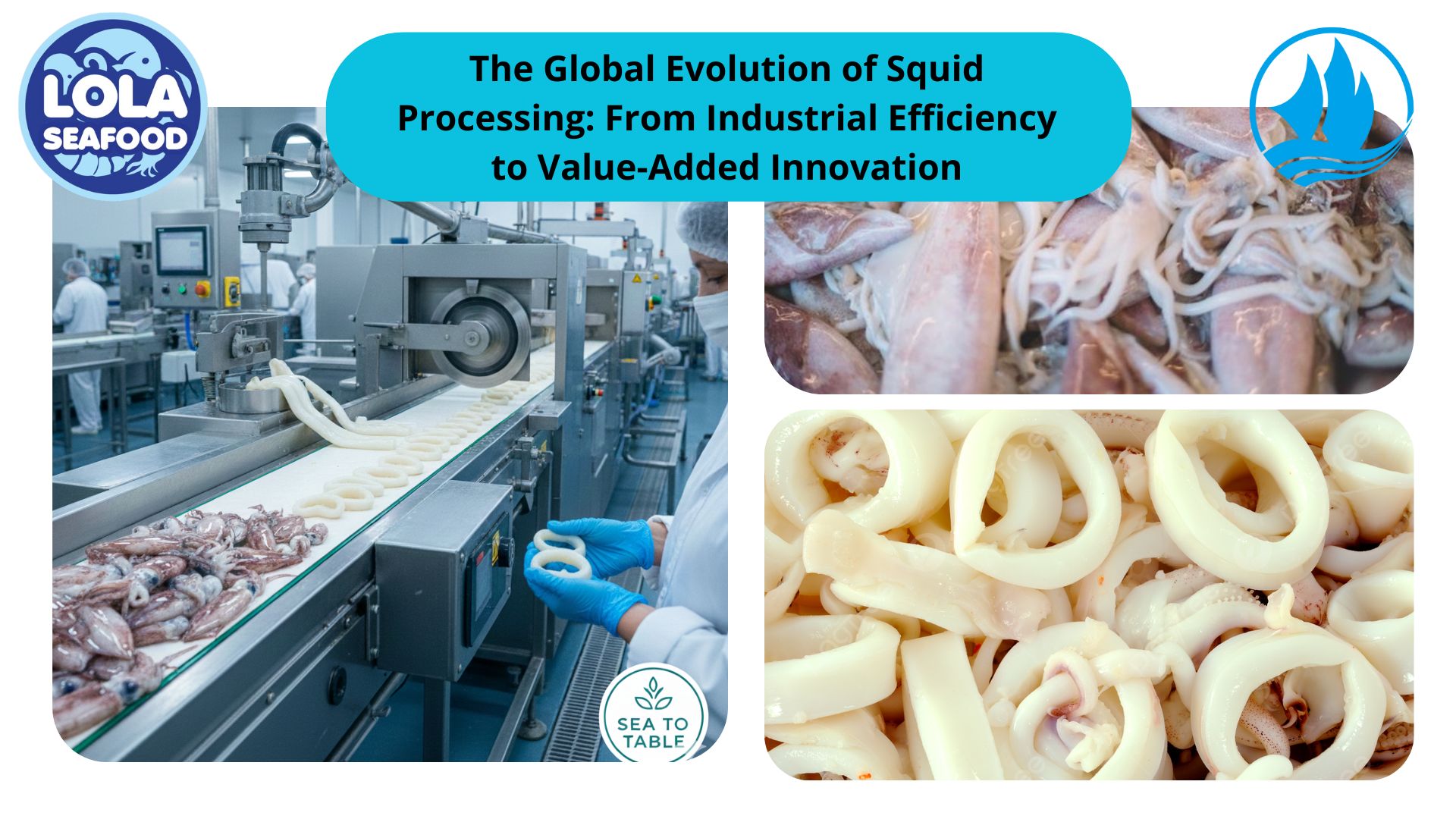

kelolalaut.com The global seafood industry has undergone a massive transformation, with squid emerging as one of the most versatile and highly traded commodities in the international market. As consumer palates evolve and the demand for protein-rich, convenient food rises, the industrial squid processing factory has become a center of high-tech innovation. Beyond the simple freezing of raw catch, modern facilities are now complex hubs that produce everything from gourmet appetizers to pharmaceutical precursors.

The Architecture of a Modern Processing Plant

A top-tier squid processing facility is designed with a linear, high-efficiency workflow that prioritizes hygiene and speed. The journey begins at the Receiving Dock, where temperature sensors ensure the catch has remained below 4oC since harvest. From here, the squid enters the Cleaning and Primary Processing zone.

In this stage, automation has largely replaced manual labor for bulk tasks. High-speed evisceration machines can process thousands of units per hour, utilizing precision blades to separate the tentacles, remove the viscera, and extract the "pen" (the internal gladius). For the premium market, "Skin-on" or "Skin-off" options are decided here. Skinning is often achieved through thermal-shock or enzymatic peeling, which removes the outer membrane without damaging the delicate white flesh of the mantle.

Diversity in Product Lines: Beyond the Basics

While the "Calamari Ring" remains the king of the retail sector, industrial plants have diversified their output to maximize the value of every kilogram of raw material.

1. The IQF (Individually Quick Frozen) Standard

The most significant advancement in preservation is Individual Quick Freezing (IQF). Unlike traditional block freezing, where squid pieces are frozen in a solid mass, IQF technology uses a fluidized bed freezer. Cold air is blown upward at high velocities, suspending the squid rings or tubes in mid-air as they freeze. This ensures that each piece remains separate, preserving the cellular integrity of the meat. When thawed, IQF squid retains its moisture and "snap," preventing the rubbery texture often associated with poorly processed seafood.

2. Value-Added and Ready-to-Cook (RTC)

The highest profit margins in the industry now come from Value-Added Products. Factories have integrated coating lines where squid rings are passed through "batter curtains" and "breading tables." These products are often pre-fried (par-fried) for a few seconds to set the coating, then flash-frozen. This allows consumers to achieve a restaurant-quality crunch in a domestic oven or air fryer.

3. Gourmet Innovations: Squid Ink and Steaks

For the culinary industry, factories extract and pasteurize Squid Ink. Once considered a waste product, it is now bottled as a gourmet coloring and flavoring agent for pasta and risottos. Similarly, for larger species like the Dosidicus gigas (Giant Squid), factories produce "Calamari Steaks." These require mechanical tenderization—a process where hundreds of tiny needles pierce the dense muscle fibers to ensure a soft, buttery texture when grilled.

Quality Assurance and Global Standards

Operating a squid factory requires strict adherence to international safety protocols. Most export-oriented plants are certified under HACCP (Hazard Analysis Critical Control Point) and BRCGS (British Retail Consortium Global Standard).

- Microbiological Testing: In-house laboratories test batches for Salmonella, Listeria, and Vibrio to ensure consumer safety.

- Metal Detection: Every finished package passes through industrial metal detectors and X-ray machines to ensure no fragments from processing machinery have entered the food chain.

- Traceability: Modern software allows a consumer to scan a QR code on a bag of frozen calamari and see exactly which FAO (Food and Agriculture Organization) fishing zone the squid came from.

Sustainability and Circular Economy

The modern squid industry is increasingly focused on "zero-waste" processing. The parts of the squid not used for human consumption—such as the viscera and skin—are diverted to secondary processing lines. These materials are rendered into Squid Liver Meal, a high-protein ingredient for the aquaculture industry, or used to extract Chitosan, a biopolymer used in water treatment and wound-healing bandages. By utilizing the "whole animal," factories reduce their environmental footprint and create additional revenue streams.

The industrial processing of squid is a testament to how technology can bridge the gap between the wild ocean and the modern kitchen. Through meticulous quality control, innovative freezing techniques, and a commitment to sustainability, these factories transform a simple cephalopod into a global culinary staple. As the industry continues to evolve, the focus remains clear: delivering freshness, safety, and variety to a hungry world.