The Imperative of Proper Fish Processing: Safeguarding Against Contamination and Organoleptic Degradation

By. Wiwik Rasmini - 01 Dec 2025

kelolalaut.com Fish and fishery products constitute a cornerstone of the global diet, prized for their high-quality protein, essential vitamins, and beneficial Omega-3 fatty acids. However, this highly valuable commodity is also inherently perishable. Once caught, fish rapidly begin to deteriorate, making the process between harvest and final consumption a critical determinant of both food safety and overall quality. Proper fish processing is not merely a matter of good practice; it is an absolute imperative to avoid the rapid proliferation of harmful bacteria and the resulting organoleptic (sensory) degradation that compromises the product and endangers the consumer.

The Twin Threats: Microbial Contamination and Spoilage

The primary hazards in fish processing can be categorized into two main areas: microbial contamination and autolytic/microbial spoilage that leads to organoleptic defects.

1. Battling Bacterial Contamination

Freshly caught fish are generally considered free of pathogenic bacteria in their muscle tissue. However, bacteria are naturally present on the skin, in the gills, and in the intestines. Upon the death of the fish, the animal’s natural defense mechanisms cease, and these microorganisms begin to rapidly multiply, invading the flesh. The high-water content, near-neutral pH (typically above 6.0), and abundance of non-protein nitrogen compounds in fish muscle provide an ideal breeding ground for both spoilage and pathogenic bacteria.

Contamination with pathogenic bacteria is frequently a result of poor hygiene and sanitation during handling and processing. Sources of contamination include:

- Contaminated Water and Ice: Using non-potable water or ice made from impure sources can introduce pathogens like E. coli, Salmonella, or Vibrio species.

- Unclean Equipment and Surfaces: Cutting boards, knives, workbenches, and storage containers that are not thoroughly cleaned and sanitized between batches become vectors for cross-contamination.

- Poor Personal Hygiene: Handlers with inadequate hygiene can transfer bacteria of human or animal origin onto the product.

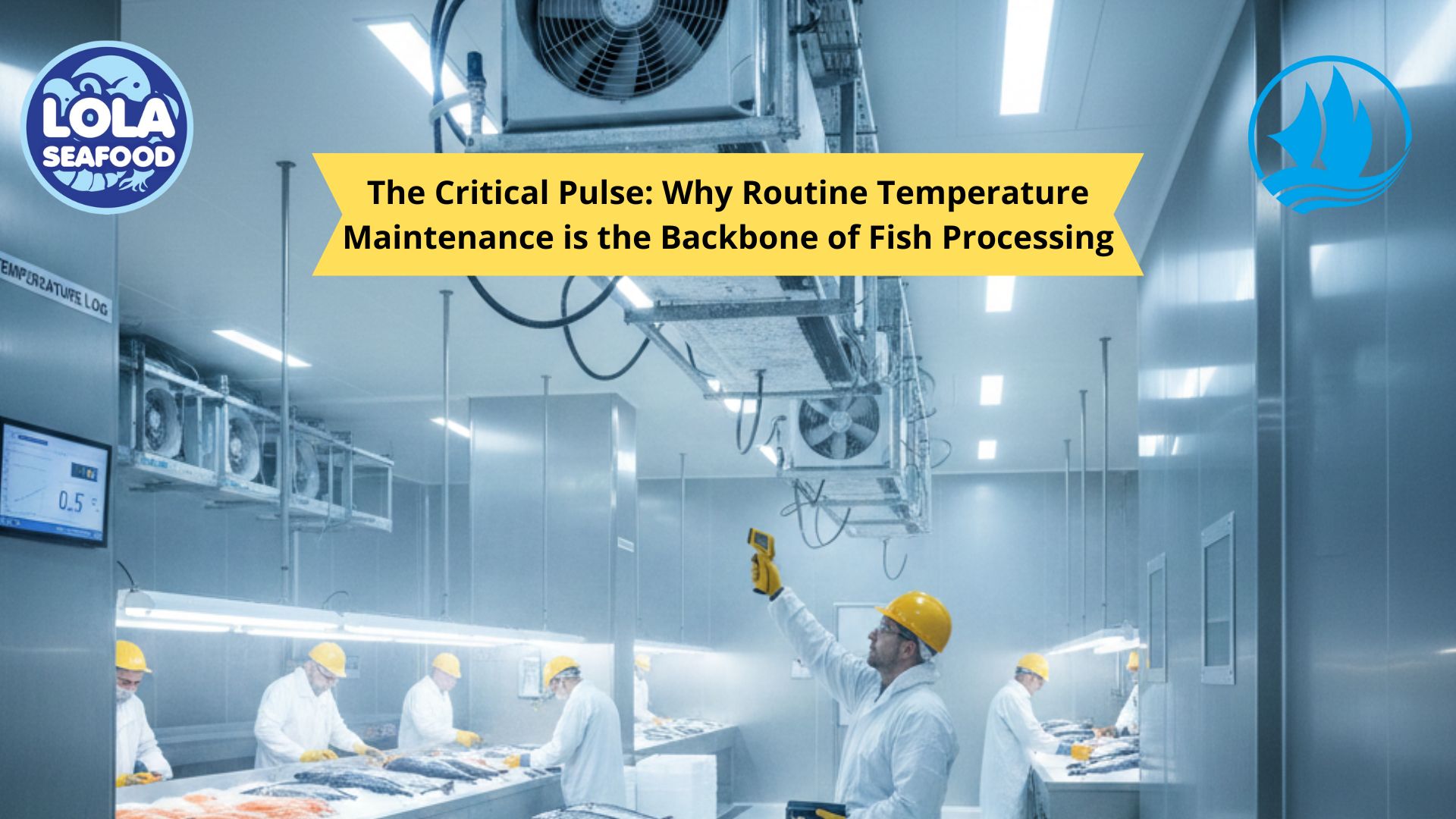

- Temperature Abuse: This is perhaps the most critical factor. Pathogenic bacteria thrive and multiply rapidly temperatures . Keeping fish at elevated temperatures, even for a short period, can result in bacterial loads reaching infectious levels.

A robust processing system, typically built around the Hazard Analysis and Critical Control Points (HACCP) concept, is essential to control these hazards. Critical Control Points (CCPs) like immediate chilling, proper gutting, and controlled cooking temperatures must be meticulously monitored and managed.

2. Preventing Organoleptic Degradation

Beyond outright contamination, fish is highly susceptible to spoilage, which impacts its sensory attributes—flavour, odour, texture, and appearance. This spoilage is a function of both endogenous (autolytic) enzymes and microbial activity.

- Autolysis: Immediately after death, the fish's own enzymes begin to break down muscle tissue, leading to initial textural and flavour changes. This process accelerates the decline in quality and provides readily available nutrients for bacterial growth.

- Microbial Spoilage: As bacteria multiply, they break down compounds like Trimethylamine Oxide (TMAO), prevalent in marine fish, into malodorous substances such as Trimethylamine (TMA). This gives the fish its characteristic 'fishy' and ultimately putrid smell. Other byproducts include ammonia and hydrogen sulfide, which severely degrade the flavour profile. Textural changes, such as softening and sliminess, also occur, rendering the product unappetizing and unacceptable to consumers.

Best Practices for Quality and Safety Assurance

To combat both microbial risks and organoleptic decline, fish processors must adhere to strict Good Manufacturing Practices (GMPs) and hygiene protocols at every stage:

- Immediate and Continuous Chilling: The single most effective action is to reduce the temperature of the fish immediately after harvest to near The use of sufficient, clean ice or mechanical chilling methods is vital. The rate of spoilage doubles or triples with every few degrees of temperature.

- Gentle Handling: Rough handling causes physical damage (bruising and tearing) that breaks the protective skin and mucus layer, allowing spoilage bacteria easier access to the muscle tissue, thereby hastening deterioration.

- Prompt Evisceration and Washing: Removing the guts as soon as possible is crucial, as the intestines contain a high concentration of both spoilage and pathogenic bacteria, as well as potent digestive enzymes that promote autolysis. The cleaned fish should then be washed with clean, chilled water to remove blood and slime.

- Sanitation of Facilities and Equipment: All surfaces that come into contact with the fish must be constructed of food-grade, easy-to-clean materials and subjected to a rigorous cleaning and sanitation schedule.

- Time-Temperature Control: Maintaining an unbroken 'cold chain' from the boat to the consumer is non-negotiable. Any lapse in temperature control for a significant time compromises both safety and quality.

In conclusion, the economic viability of the fish processing industry hinges on its ability to deliver a safe and high-quality product. Failing to implement proper processing methods, especially in controlling temperature and maintaining hygiene, leads to rapid bacterial contamination, the generation of harmful biogenic amines, and the severe loss of organoleptic quality. By adhering to strict HACCP and GMP principles, processors not only protect public health but also preserve the superior nutritional and sensory value of the final product, reinforcing consumer trust and ensuring sustainability in the global seafood market.