From Ocean to Your Plate: The High Standards of Quality in Every Frozen Fish Fillet

By. Wiwik Rasmini - 27 Nov 2025

kelolalaut.com In today's fast-paced world, convenience often comes at the cost of quality. However, when it comes to frozen fish, this is a misconception we aim to debunk. Modern freezing technology and stringent quality control measures ensure that frozen fish fillets can offer the same, if not superior, nutritional value and flavor as their fresh counterparts. The journey from the vast, pristine ocean to your dining table is a meticulously managed process, underpinned by high standards that guarantee quality in every single fillet.

The narrative of "fresh is best" has long dominated the seafood market, yet it overlooks the practical realities of sourcing and consuming fish globally. Fish, being a highly perishable commodity, begins to degrade moments after being caught. Enzymes and bacteria immediately start to break down its cellular structure, affecting taste, texture, and nutritional content. This is where the magic of modern freezing technology truly shines. By rapidly freezing fish at its peak freshness, this degradation process is halted, effectively locking in all the desirable characteristics.

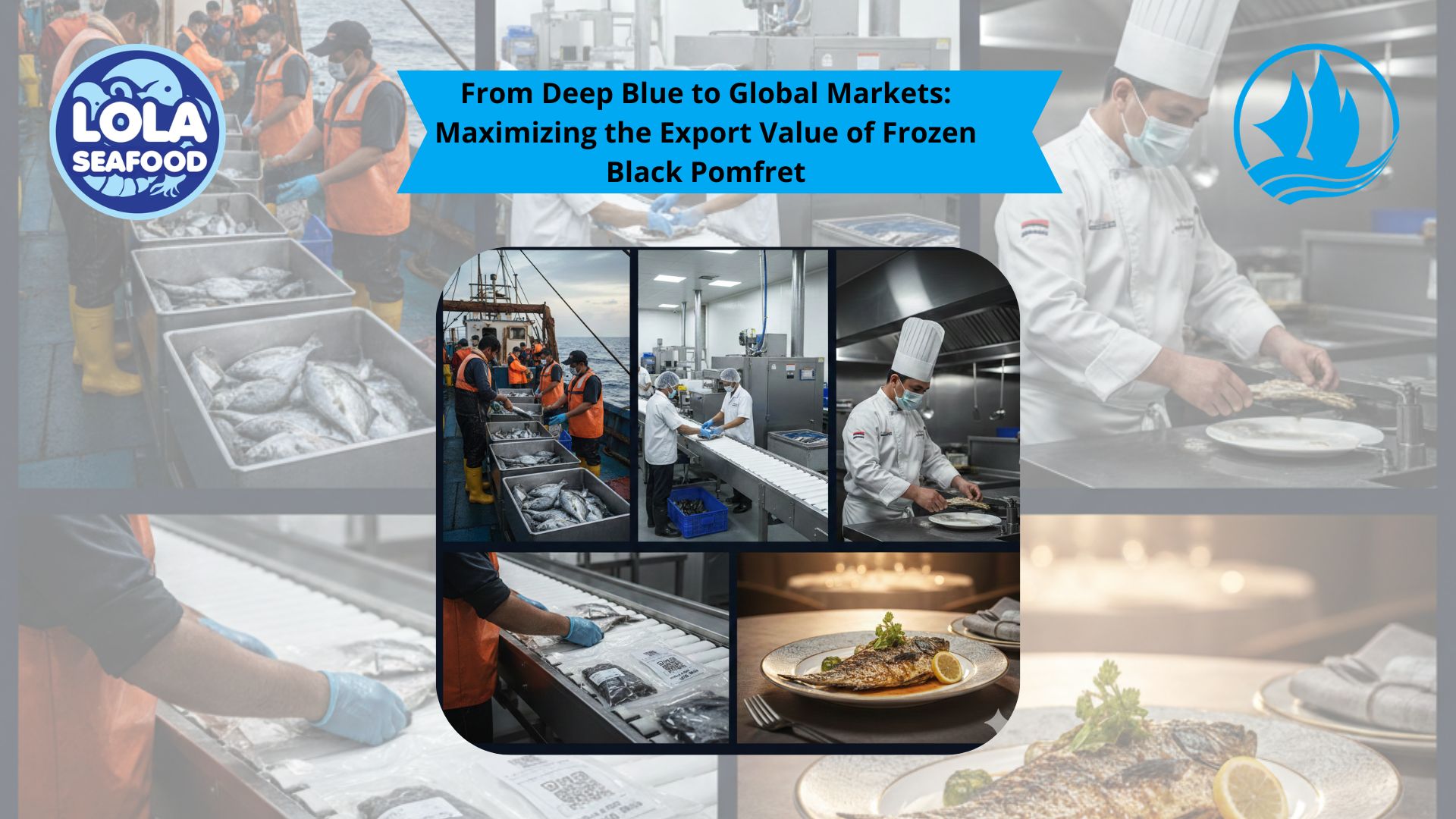

The Catch: Sourcing and Initial Handling

The commitment to quality begins even before the fish leaves the water. Reputable frozen fish suppliers prioritize sustainable fishing practices, ensuring that the ecosystems are preserved for future generations. This often involves working with certified fisheries that adhere to strict quotas and environmentally friendly catching methods. Once caught, the handling of the fish is critical. It must be immediately sorted, cleaned, and often rapidly chilled on board the vessel. This initial rapid chilling, sometimes called "super chilling" or "slurry ice," is a crucial first step to maintain freshness before processing. Minimizing the time between catch and chilling is paramount to preventing bacterial growth and maintaining the fish's natural quality.

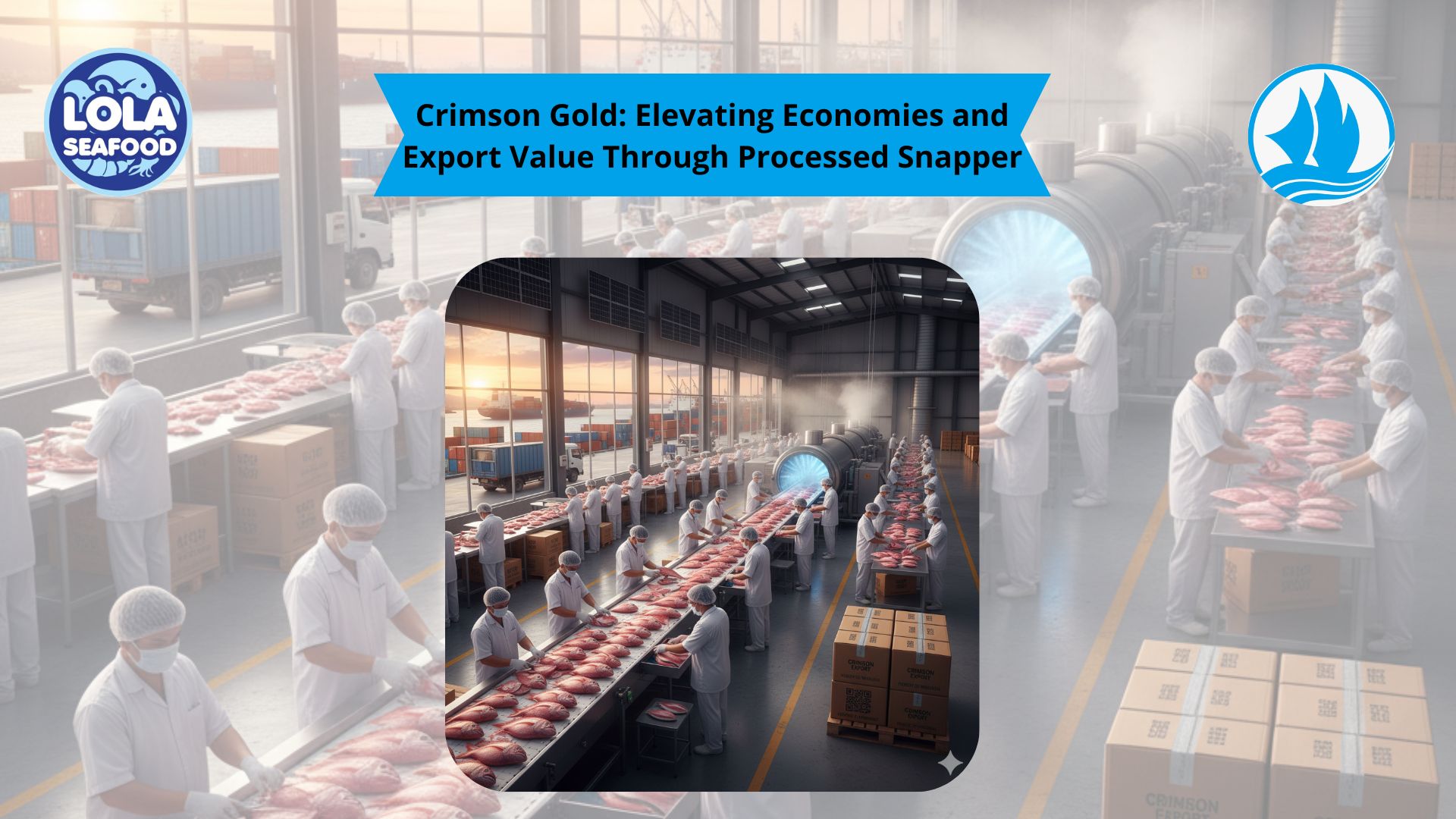

The Processing Plant: A Hub of Hygiene and Precision

Upon arrival at the processing plant, the fish undergoes a transformation within a highly controlled environment. These facilities are not just factories; they are sophisticated operations designed with hygiene, efficiency, and food safety at their core.

- Inspection and Sorting: Each fish is thoroughly inspected upon arrival to ensure it meets quality parameters. Any fish not meeting these standards is rejected.

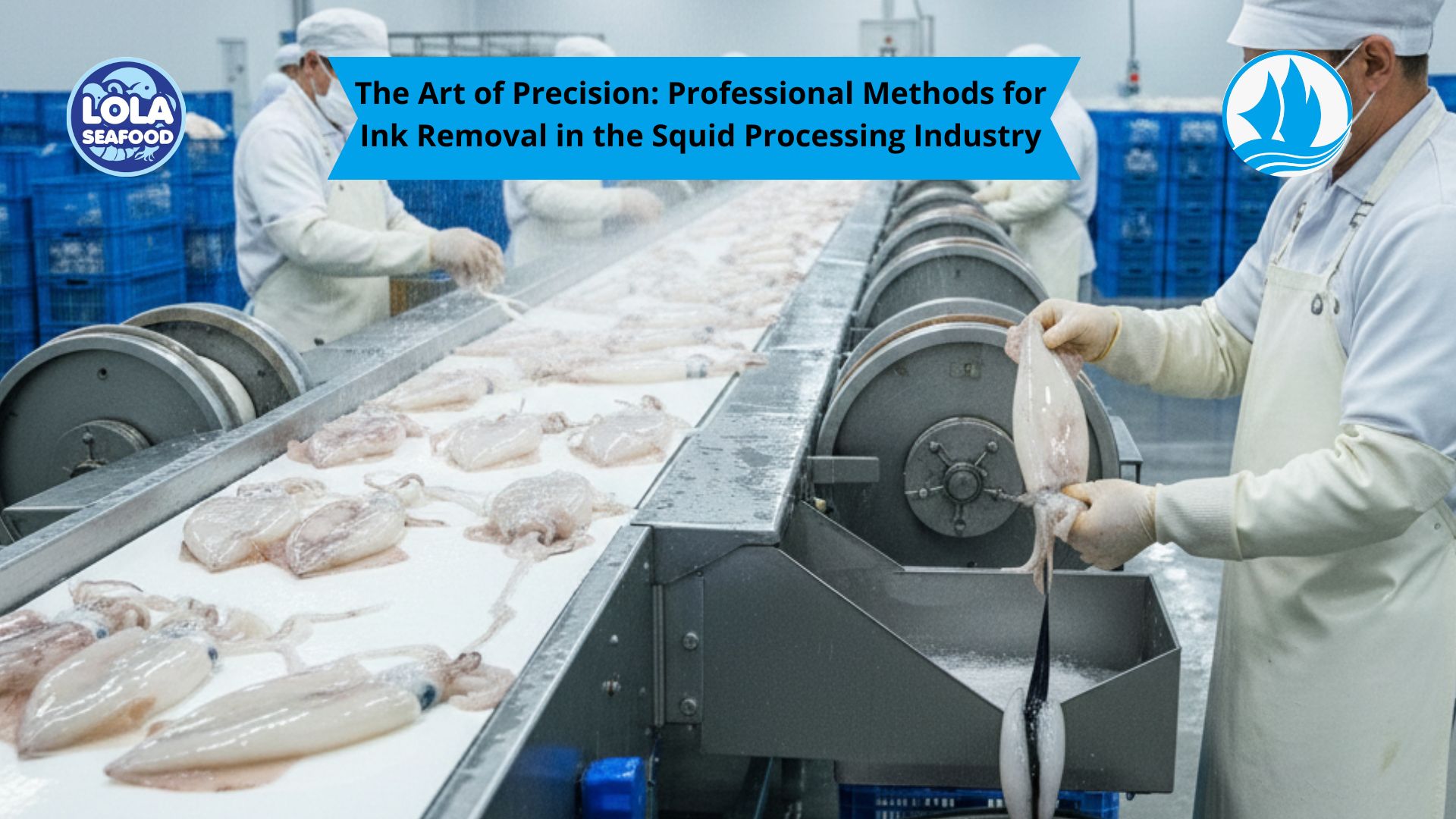

- Filleting and Trimming: Skilled workers, often employing automated machinery for consistency, carefully fillet the fish. This process requires precision to maximize yield while removing bones and undesirable parts. The fillets are then meticulously trimmed to ensure uniformity in size and appearance, reflecting the premium standard of the product.

- Washing and Cleaning: The fillets are washed with purified water to remove any lingering impurities, ensuring a clean and fresh product.

- Rapid Freezing: This is arguably the most critical step. Unlike slow freezing, which can form large ice crystals that damage cell structures and lead to a mushy texture upon thawing, rapid freezing (often using methods like Individual Quick Freezing or IQF, blast freezing, or cryogenic freezing) forms tiny ice crystals. These small crystals preserve the cellular integrity of the fish, maintaining its firm texture, vibrant color, and natural flavor. The quicker the freeze, the better the quality.

Quality Control: From HACCP to Your Home

Throughout the entire process, stringent quality control measures are in place. Modern processing plants operate under internationally recognized food safety management systems such as HACCP (Hazard Analysis and Critical Control Points) and ISO certifications.

- Temperature Monitoring: Every stage, from chilling on the boat to freezing and storage, is rigorously monitored for temperature consistency. Any deviation can compromise quality and safety.

- Microbiological Testing: Regular tests are conducted on the fish, water, and surfaces within the plant to detect and prevent any bacterial contamination.

- Sensory Evaluation: Trained quality control personnel regularly assess samples for appearance, odor, texture, and flavor, ensuring that only the highest quality fillets make it to packaging.

- Traceability: Advanced traceability systems allow each fillet to be tracked back to its origin, including the fishing vessel, catch date, and processing batch. This provides an unparalleled level of transparency and accountability, offering consumers peace of mind.

Packaging and Distribution: Preserving Perfection

Once frozen, the fillets are carefully packaged, often vacuum-sealed, to prevent freezer burn and protect against oxidation, which can affect flavor and texture. The packaging also provides vital information such as nutritional facts, cooking instructions, and best-before dates.

The journey doesn't end there. The frozen fillets are then transported in temperature-controlled environments, maintaining the cold chain from the plant to the distributor, and eventually to the retail store or your doorstep. This unbroken cold chain is essential to ensure that the fish remains perfectly frozen until it reaches your kitchen.

The Advantage for Consumers

The result of this rigorous process is a product that offers immense benefits to the consumer:

- Convenience: Frozen fillets are ready to cook, saving preparation time.

- Reduced Waste: You only use what you need, minimizing food waste.

- Consistent Quality: Thanks to controlled processing, you can expect consistent texture and flavor.

- Nutritional Value: Rapid freezing locks in essential nutrients like Omega-3 fatty acids, vitamins, and minerals.

- Year-Round Availability: Enjoy your favorite fish regardless of seasonal availability.

In conclusion, the journey of a frozen fish fillet from the ocean to your plate is a testament to dedication and advanced technology. It's a journey marked by sustainable sourcing, meticulous processing, and unwavering commitment to quality and safety. So, the next time you reach for a frozen fish fillet, you can be confident that you are choosing a product that has been handled with the highest standards, delivering convenience, nutrition, and deliciousness straight to your home.

If youre interested in our Barramundi Whole Round / Whole Gilled Gutted Scaled , Barramundi Fillet Skinless , Barramundi Fillet Skin On and Barramundi Fillet Portion Cut, snapper please do not hesitate to contact us through email and/or Whatsapp

.jpg)