The Importance of Proper Placement and Separation of Fish Species in the Fish-Processing Industry

By. Lutfi - 19 Nov 2025.jpg)

kelolalaut.com The fish-processing industry is a vital part of the global food supply chain, providing consumers with high-quality seafood products while supporting economic growth in many coastal regions. To maintain high standards of safety, quality, and efficiency, one important practice stands out: the proper placement and separation of fish species during every stage of processing. From receiving raw materials to packaging finished products, careful separation ensures that processors meet regulatory requirements, maximize product value, and protect consumer health. This article explores why proper handling and segregation of different fish species are essential in modern seafood processing.

Ensuring Food Safety and Preventing Cross-Contamination

One of the primary reasons for separating fish species is to minimize the risk of cross-contamination. Each species may carry different levels of microorganisms, parasites, and natural toxins. For example, oil-rich fish like mackerel or sardines spoil more quickly due to their high lipid content, whereas lean species such as cod or tilapia remain stable for longer periods. If these species are mixed during processing or storage, the faster-spoiling fish can accelerate the deterioration of the entire batch, compromising safety and quality.

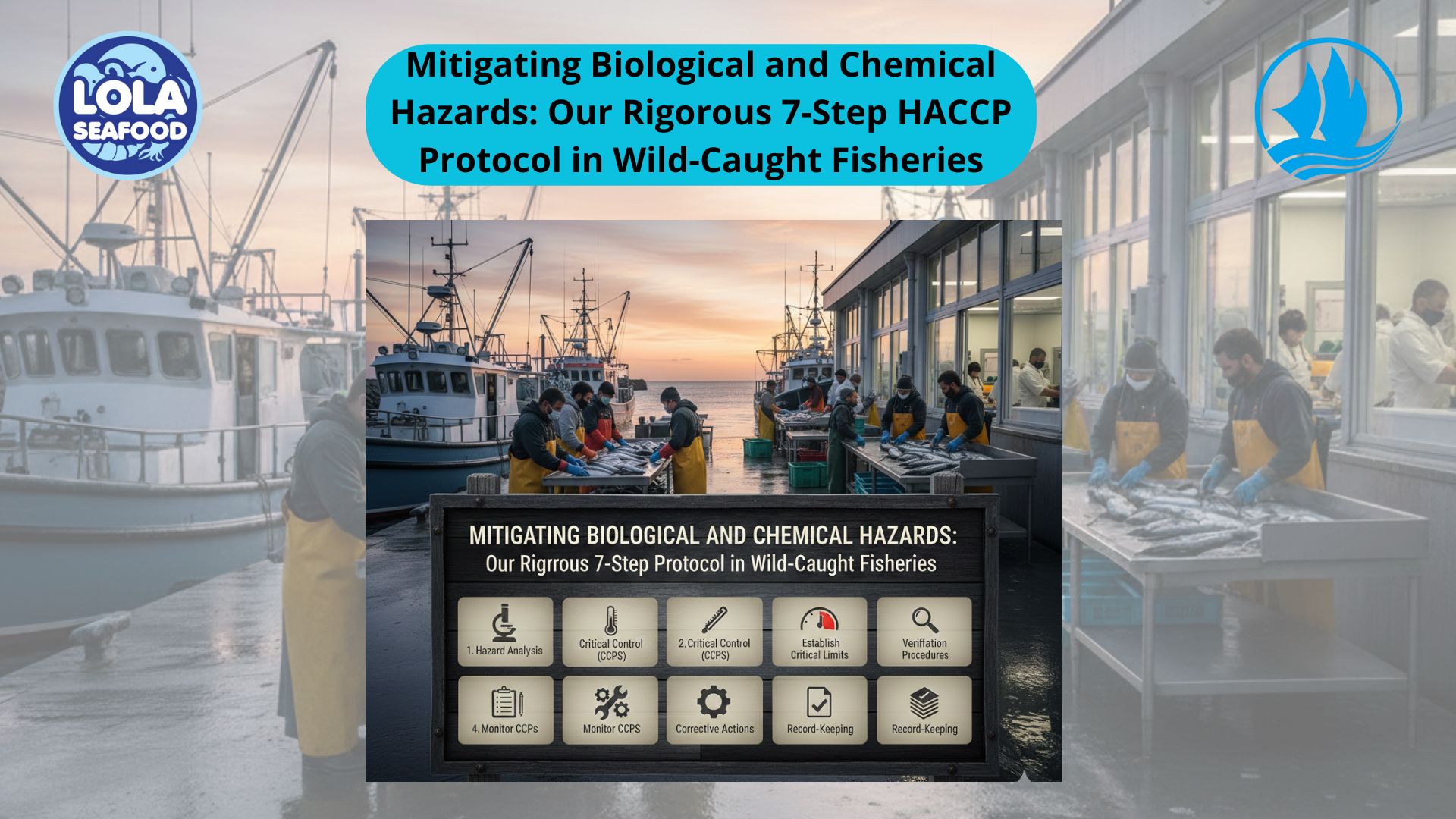

Another important factor is allergen control. Some individuals have allergies to particular fish species, and accidental mixing can cause severe reactions. The fish-processing industry is required to follow strict food safety guidelines, including HACCP, which emphasize the importance of allergen management. Proper segregation of species ensures that allergenic materials do not contaminate other products, reducing health risks for consumers and minimizing the possibility of regulatory penalties.

Maintaining Product Quality and Freshness

Different fish species have unique biological compositions, including variations in fat, moisture, and muscle structure. These characteristics influence how the fish must be handled, processed, and preserved. For instance, salmon and tuna require specific temperature controls to maintain freshness and prevent oxidation of their natural oils. Meanwhile, whitefish species such as haddock or snapper may need different handling methods to maintain their delicate texture.

If fish are not properly separated, processors might apply uniform handling procedures that are unsuitable for certain species. This can lead to texture degradation, discoloration, off-flavors, or a shorter shelf life. Separating species allows processors to tailor their methods to each type of fish, ensuring optimal freshness and preserving the natural characteristics that consumers expect. High-quality products not only satisfy customers but also enhance brand reputation in competitive markets.

Improving Processing Efficiency and Reducing Operational Costs

Operational efficiency is essential in the fish-processing industry, where large volumes of fish must be processed in a timely manner. Sorting fish by species, size, and quality helps streamline workflow and increase overall productivity. Many types of processing equipment—such as skinning machines, filleting machines, and deboners—are designed to handle specific fish sizes and structures. Mixing different species can lead to equipment malfunctions, uneven cuts, and higher waste levels.

Proper separation also reduces the need for frequent equipment adjustments, allowing production lines to operate continuously and efficiently. This not only saves time but also reduces labor costs and minimizes downtime. When fish are organized correctly from the moment they arrive at the facility, workers can follow a smooth, well-structured workflow that contributes to consistent output and better use of resources.

Supporting Traceability and Regulatory Compliance

Traceability is becoming increasingly important in the seafood industry, especially for products entering international markets. Consumers and regulatory agencies want to know the origin, species, and handling history of the fish they purchase. To meet these expectations, processors must maintain accurate records, and this process begins with the correct identification and separation of fish species.

Improper sorting can lead to mislabeling, which not only undermines consumer trust but may also result in legal consequences. Furthermore, specific species may be subject to different regulations depending on their conservation status or fishing method. Clear and consistent separation ensures that each product can be traced back to its source, helping companies comply with local and global standards while avoiding costly violations.

Enhancing Market Value and Product Consistency

Market value is greatly influenced by product consistency. Buyers expect seafood products to meet specific standards in terms of appearance, size, and quality. When fish of different species or sizes are processed together, the resulting products may vary significantly, leading to customer dissatisfaction and decreased market value.

Premium markets, such as those for sashimi-grade tuna or high-end salmon fillets, require precise handling and strict species separation. Even minor mistakes can downgrade a high-value product into a lower market category. By properly separating fish, companies can maintain product uniformity, enhance visual appeal, and achieve higher selling prices.

If youre interested in our Barramundi Whole Round / Whole Gilled Gutted Scaled , Barramundi Fillet Skinless , Barramundi Fillet Skin On and Barramundi Fillet Portion Cut, snapper please do not hesitate to contact us through email and/or Whatsapp

.jpg)