Optimizing Wild-Caught Fish Logistics: Maintaining Thermal Core Integrity During Long-Haul Transport

By. Sofie Thoriq - 29 Dec 2025

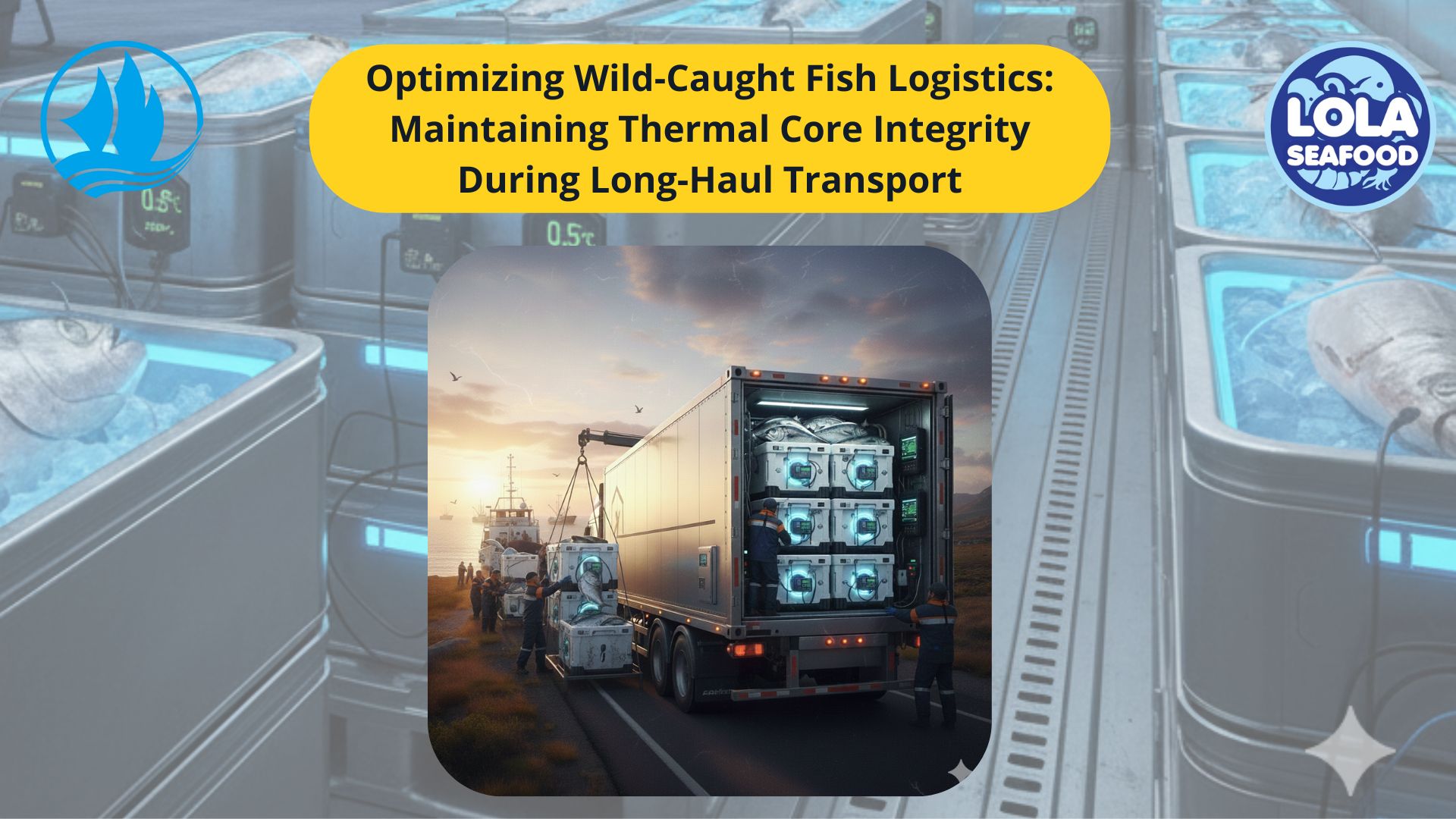

kelolalaut.com The global seafood industry is a race against time and biology. For wild-caught fish, the moment they leave the water, a countdown begins. Unlike farmed fish, which are harvested in controlled environments, wild-caught species are often subjected to varying environmental stressors before they even reach a processing facility. The single most critical factor in winning this race is the management of the Thermal Core—the internal temperature at the thickest part of the fish.

In long-haul logistics, maintaining a cold chain isn't just about keeping the air in a truck chilly; it is about precision thermal engineering to ensure the fish’s core remains at a constant, optimal temperature to prevent degradation.

The Science of the Thermal Core

When we talk about "keeping fish cold," we often focus on surface temperature. However, the thermal core is where the real battle for quality is fought. Fish muscle is high in water and protein, making it an excellent conductor of heat but also a prime breeding ground for bacteria if the internal temperature rises.

As soon as a fish dies, enzymes begin to break down tissues (autolysis), and naturally occurring bacteria start to multiply. The rate of these biochemical reactions is dictated by the Arrhenius Equation, which essentially states that for every 10oC increase in temperature, the rate of spoilage doubles or even triples.

To achieve a shelf life of 10–15 days for fresh fish, the core temperature must be brought down to near-freezing (0oC to 2oC) as rapidly as possible and held there without fluctuation.

Challenges in Long-Haul Transportation

Transporting fish over thousands of miles—from remote coastal landing sites to urban centers or international airports—presents three primary challenges:

- Initial Heat Load: Fish caught in tropical or temperate waters often have a high initial body temperature. If this "field heat" isn't removed immediately, the core remains warm even if the exterior is covered in ice.

- Thermal Infiltration: No insulation is perfect. Heat penetrates through truck walls, floorboards, and door seals. In long-haul journeys, even a minor "cold bridge" can cause a gradual rise in the internal temperature of the cargo.

- The "Air Void" Effect: In refrigerated containers (reefers), air follows the path of least resistance. If the cargo is not packed correctly, cold air bypasses the fish pallets, leaving "hot spots" in the center of the load where the thermal core of the fish can rise dangerously.

Strategies for Core Temperature Optimization

1. Pre-Chilling: The Critical First Step

Logistics optimization begins before the truck even arrives. Using Slurry Ice (a mixture of microscopic ice crystals and seawater) is the most effective way to drop the core temperature. Because slurry ice wraps entirely around the fish, it has a much higher surface-to-volume contact area than flake ice, cooling the core up to four times faster.

2. Advanced Insulation and Phase Change Materials (PCMs)

Standard Styrofoam is increasingly being replaced by high-performance vacuum insulation panels and Phase Change Materials. PCMs are substances that absorb or release thermal energy during the process of melting or freezing. By lining transport boxes with PCMs calibrated to 0oC, logistics providers can create a "thermal buffer" that maintains the core temperature even if the vehicle's refrigeration unit fails.

3. Real-Time IoT Monitoring

Modern long-haul logistics rely on Internet of Things (IoT) sensors. These aren't just thermometers on the wall of the truck; they are "probes" or "data loggers" placed inside the fish boxes. These devices transmit real-time data via satellite, allowing fleet managers to see the actual thermal core environment. If a temperature spike is detected, the driver can be alerted to check the cooling system before the damage becomes irreversible.

The Economic and Sustainability Impact

Optimizing the thermal core isn't just about food safety; it’s about economics. Post-harvest loss in the fisheries sector is a massive global issue, with some estimates suggesting up to 25% of wild-caught fish is wasted due to poor temperature control.

By maintaining the thermal core:

- Shelf life is extended: Reducing waste and allowing for slower, cheaper transport methods (like sea freight instead of air freight).

- Texture and Flavor are preserved: Preventing "gaping" (tissue breakdown) and the development of "off-flavors" caused by lipid oxidation.

- Market Value is maximized: High-quality "sashimi-grade" fish requires perfect thermal history to command premium prices.

in Modern Fish Processing Industries.jpg)