Delivering Freshness: Inside Our Modern Seafood Processing Facility

By. Sofie Thoriq - 12 Jan 2026

kelolalaut.com The journey of a fish from the depths of the ocean to the center of a dinner plate is a race against time. In the seafood industry, "freshness" isn't just a marketing buzzword; it is a rigorous technical standard that dictates quality, safety, and flavor. At our modern seafood processing facility, we have bridged the gap between the wild sea and the urban kitchen through cutting-edge technology, sustainable practices, and an uncompromising cold chain.

The Foundation: Speed and Proximity

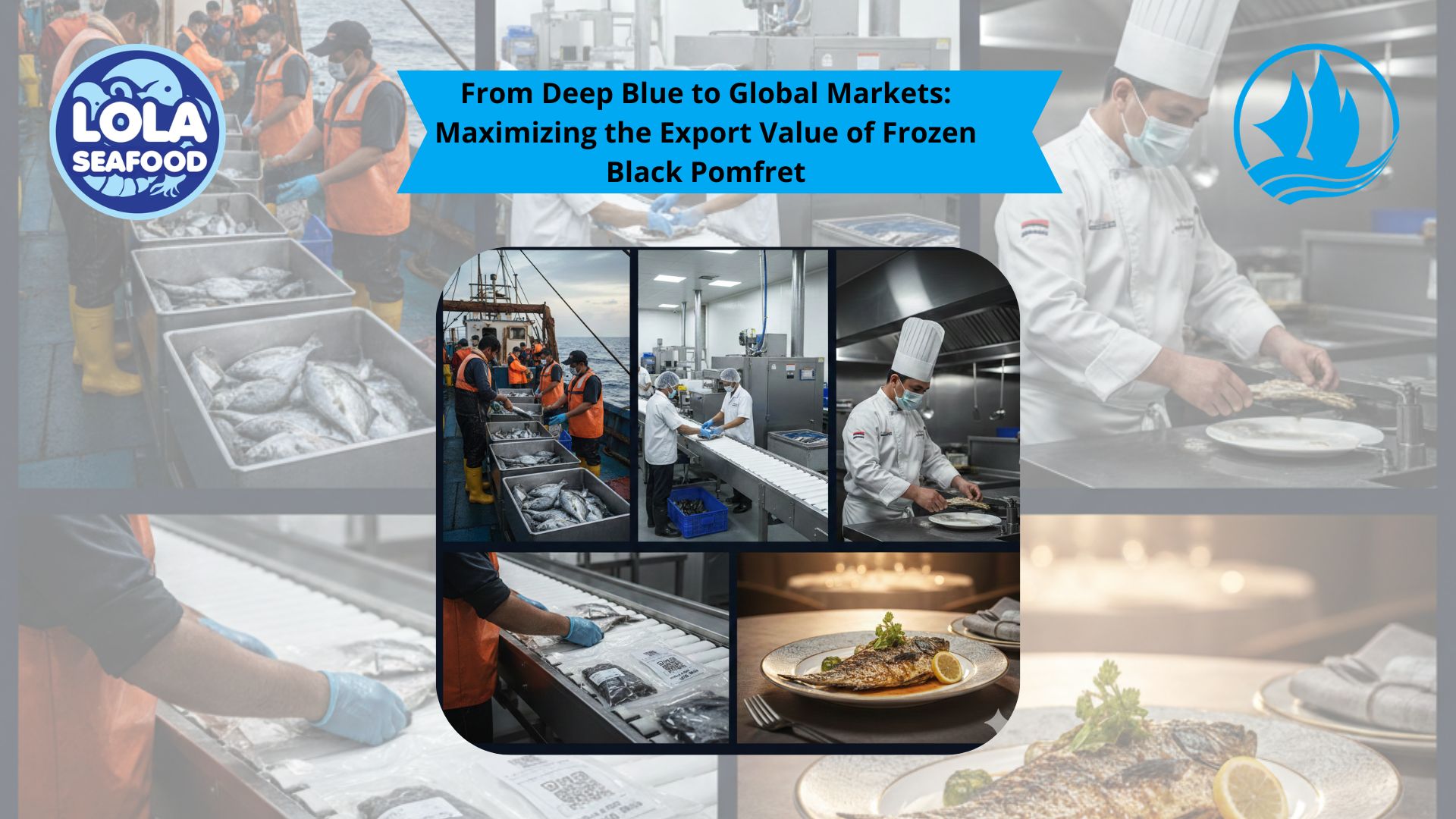

Freshness begins long before the product reaches our gates. Our facility is strategically located near major landing ports, ensuring that the time elapsed between harvest and processing is kept to an absolute minimum. We work exclusively with a fleet of trusted vessels equipped with On-Board Seaquench systems that begin the chilling process the moment the catch is hauled in.

When the raw material arrives at our receiving docks, every second counts. Our intake process is streamlined to ensure that seafood moves from the refrigerated hold of a vessel into our temperature-controlled environment within minutes. This immediate transition prevents the enzymatic breakdown that compromises the texture and taste of premium seafood.

Cutting-Edge Processing Technology

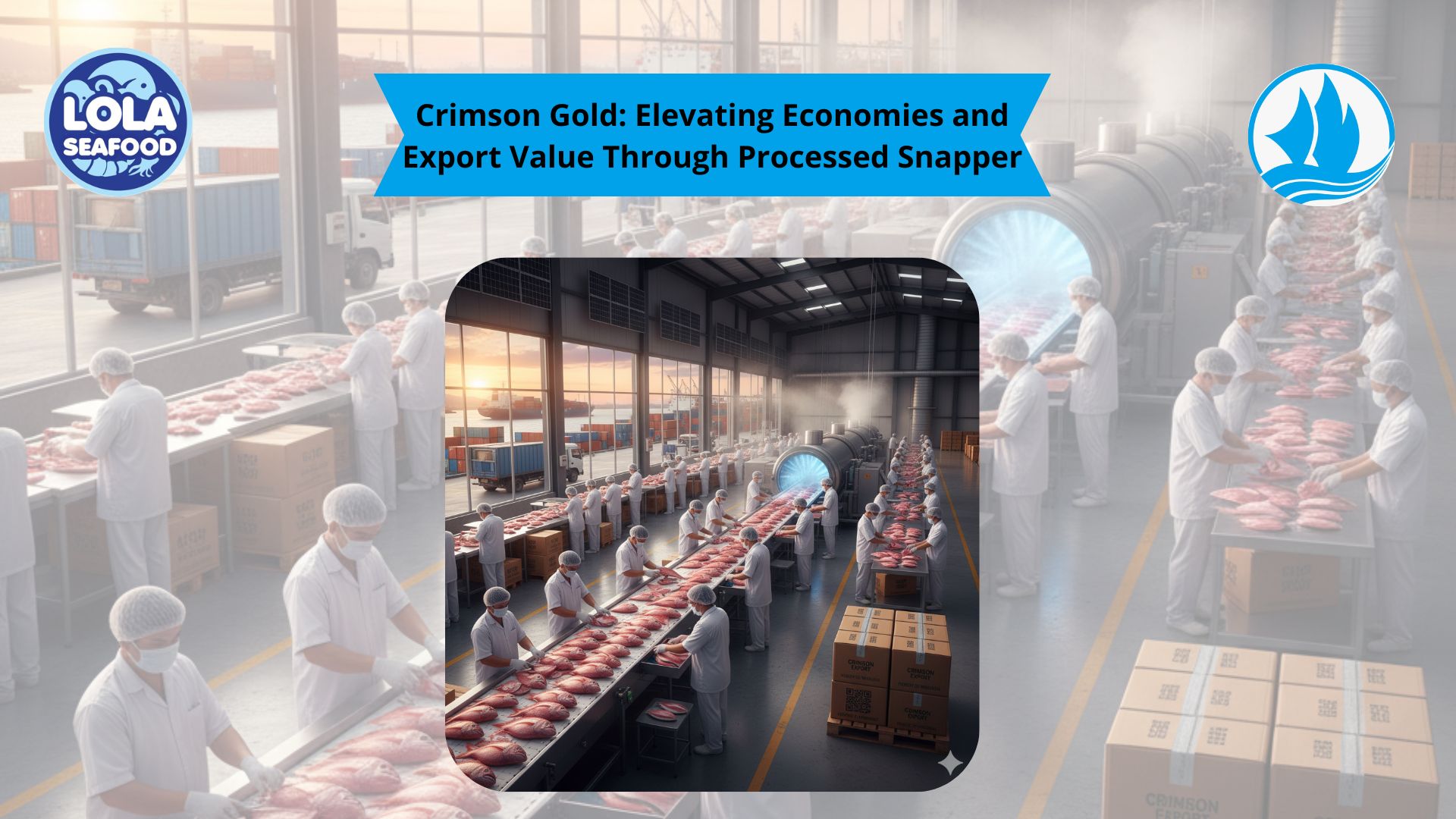

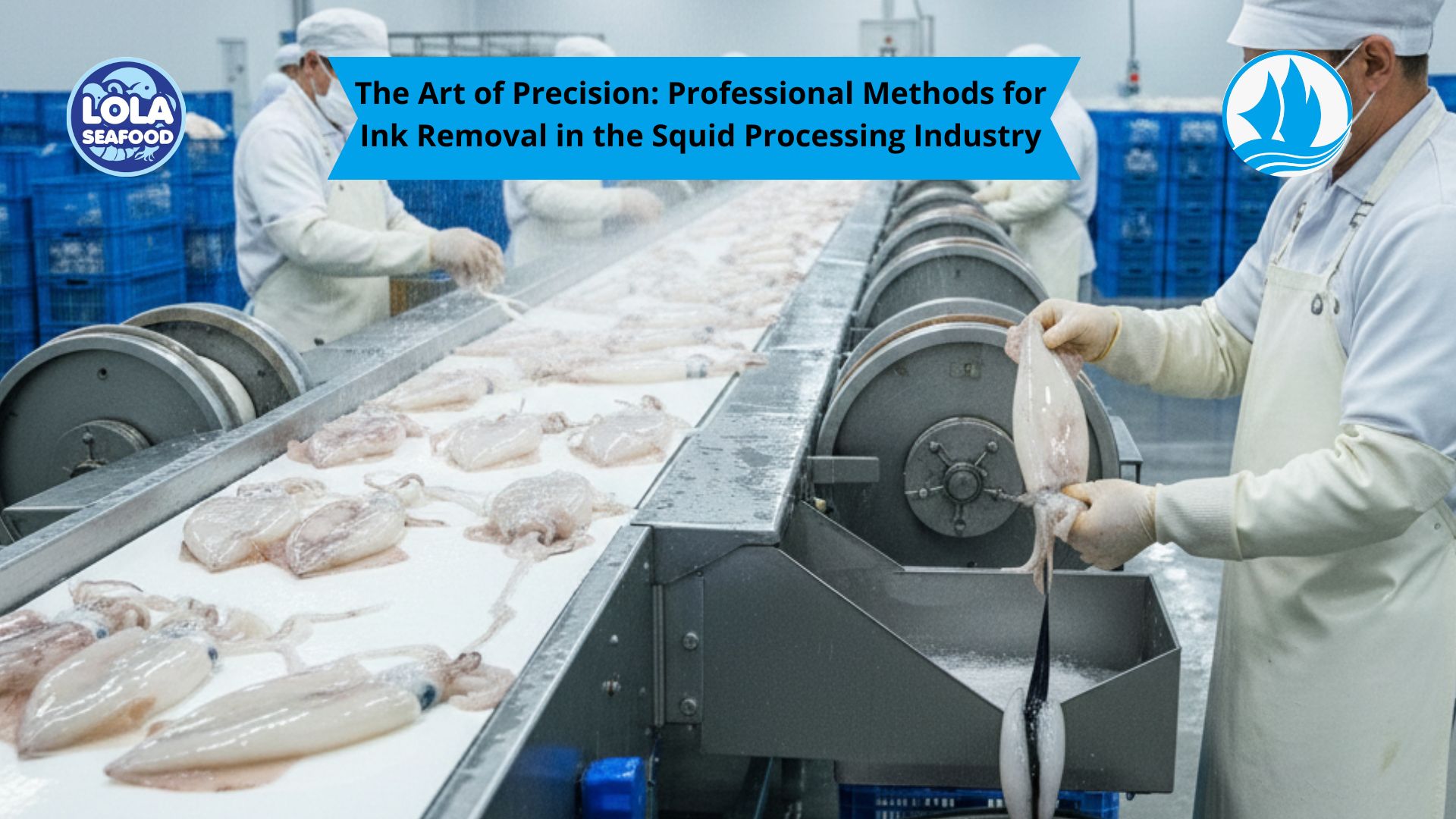

Inside the facility, the environment is a marvel of modern engineering. We operate under a strict HACCP (Hazard Analysis and Critical Control Points) framework, but we go beyond regulatory requirements by integrating automated precision tools.

- Automated Filleting and Portioning: Using high-speed laser scanning technology, our machines calculate the optimal cut for every fish, maximizing yield and ensuring uniform thickness. This precision ensures that whether you are a retail consumer or a restaurant chef, every piece of seafood cooks evenly.

- Ultrasonic Cleaning: To ensure the highest levels of food safety, we utilize ultrasonic cleaning baths for certain shellfish varieties. This technology uses high-frequency sound waves to remove microscopic impurities without the need for harsh chemicals, preserving the natural salinity and sweetness of the product.

- Modified Atmosphere Packaging (MAP): For our fresh retail lines, we utilize MAP technology. By replacing the oxygen inside the packaging with a specific blend of inert gases, we naturally slow down the oxidation process. This extends the shelf life of the product by several days without the use of artificial preservatives.

The Science of the "Super-Freeze"

While "fresh" often refers to never-frozen products, modern technology has redefined what it means to be "frozen." For our long-distance exports, we employ Cryogenic Flash-Freezing.

Unlike conventional home freezers that freeze food slowly—allowing large ice crystals to form and puncture the cellular walls of the fish—our cryogenic tunnels use liquid nitrogen to drop temperatures to -60°C in seconds. This "locks in" the moisture and nutrients at the cellular level. When the consumer thaws this seafood, the texture is indistinguishable from a fish caught that morning. We call this "Fresh-Frozen," a gold standard that allows us to deliver seasonal delicacies year-round without losing a hint of quality.

Sustainability and Traceability

A modern facility must be as responsible as it is efficient. We believe that delivering freshness today should not compromise the oceans of tomorrow. Our facility is powered by a hybrid solar-grid system, and we have implemented a Zero-Waste Policy. Every part of the fish that isn't used for human consumption—such as trimmings and bones—is repurposed into high-quality fish oils or organic fertilizers.

Furthermore, transparency is at the heart of our operations. Every batch of seafood that enters our facility is assigned a Digital Passport via blockchain technology. By scanning a QR code on the final packaging, customers can see:

- The exact vessel that caught the fish.

- The GPS coordinates of the catch area.

- The timestamp of when it was processed in our facility.

The Human Element

Despite the high level of automation, the human touch remains irreplaceable. Our quality control team consists of seasoned experts who perform sensory evaluations on every batch. They check for the clarity of the eyes, the brightness of the gills, and the firm "spring-back" of the flesh—nuances that even the most advanced sensors can sometimes overlook. Our staff undergoes continuous training in food safety and sustainable handling, ensuring that the passion for the craft is present in every fillet we produce.

.jpg)