Sanitation as a Critical Control Point: Protecting Fish Products from Contamination

By. Wiwik Rasmini - 25 Aug 2025

Kelolalaut.com Seafood is one of the most perishable food commodities in the world. Its high moisture content and nutrient-rich composition make fish an ideal environment for microbial growth. In seafood processing facilities, even the smallest oversight in hygiene can quickly escalate into a serious food safety problem. A single contaminated piece of equipment may spread bacteria across an entire production line, causing recalls, financial losses, and damage to brand reputation.

This reality underscores why sanitation is not just a supportive activity, but often a Critical Control Point (CCP) within a Hazard Analysis and Critical Control Points (HACCP) system. Recognizing the role of sanitation as a frontline defense helps the fishing industry prevent contamination and deliver safe, high-quality products to consumers.

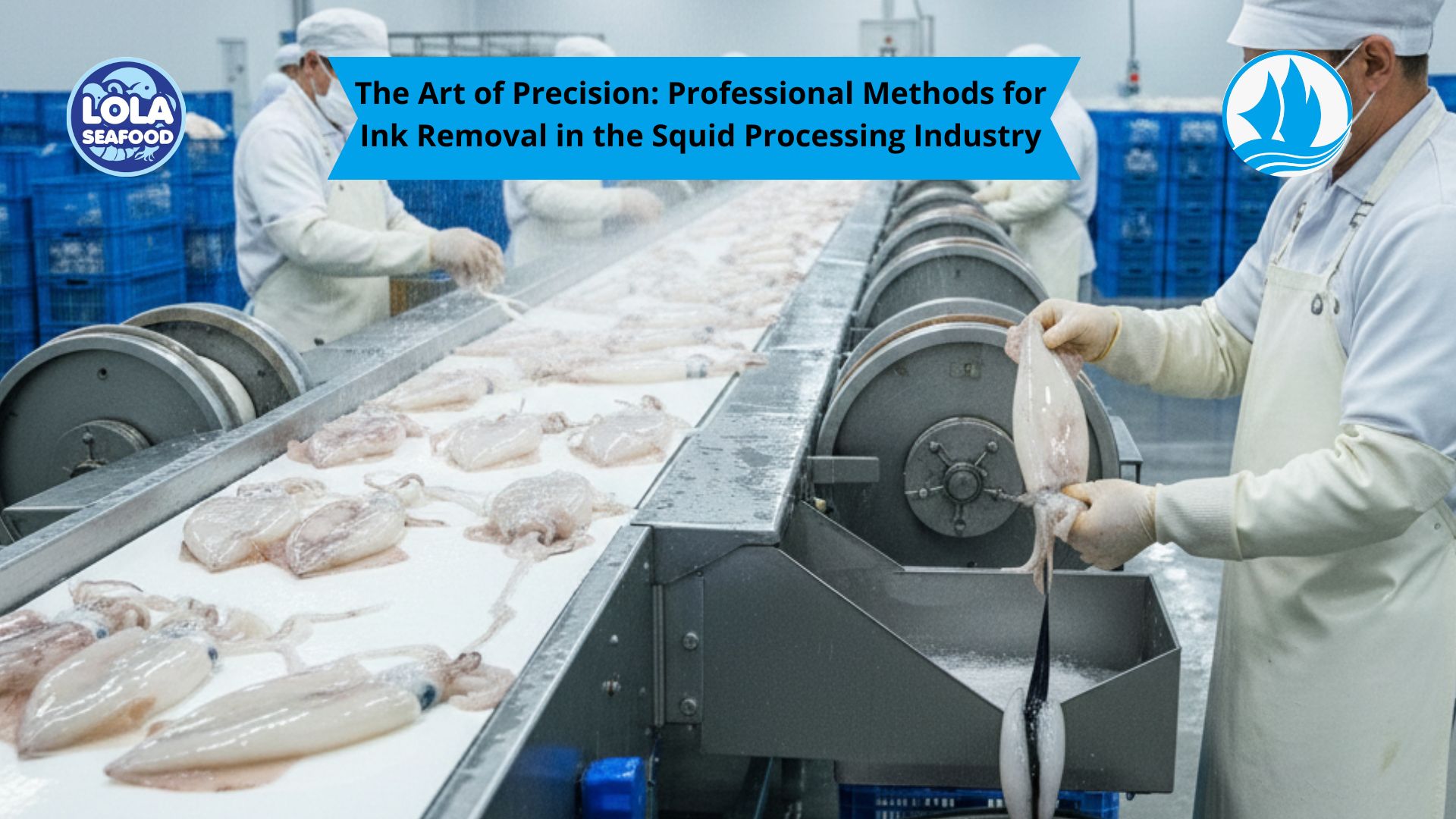

The Hidden Risks of Unsanitized Equipment

Unlike chemical residues or foreign objects, microbial contamination is invisible to the naked eye. A conveyor belt that looks clean may still harbor Listeria monocytogenes, a pathogen that thrives in cold, damp conditions typical of seafood plants. Similarly, filleting knives or cutting boards, if not properly sanitized, can carry bacteria from one batch of fish to another.

Cross-contamination does not only involve microorganisms. Allergen risks also emerge when residues of one species, such as shellfish, come into contact with another. For consumers with allergies, this can lead to life-threatening reactions. These risks illustrate why regulators and buyers place sanitation at the heart of food safety programs.

HACCP and the Recognition of Sanitation as a CCP

The HACCP framework requires food processors to identify and control hazards that could endanger consumer health. While many hazards are managed through process controls such as cooking temperatures or packaging integrity, sanitation is unique because it directly underpins the effectiveness of all other controls.

When sanitation is defined as a CCP, it means that failure in cleaning and disinfecting equipment poses an unacceptable risk to food safety. For fish processors, this decision is not only about meeting legal requirements but also about ensuring product integrity from catch to consumer.

Building a Strong Sanitation CCP

Integrating sanitation into a HACCP plan involves more than just scheduling cleaning routines. It requires systematic planning, monitoring, and verification. Successful facilities often incorporate the following measures:

- Sanitation Standard Operating Procedures (SSOPs): Detailed step-by-step instructions for cleaning each type of equipment.

- Critical Limits: Clear benchmarks such as water temperature, chemical concentration, or acceptable microbial counts.

- Monitoring Systems: Daily checklists, microbial swabs, or rapid ATP tests to confirm equipment hygiene.

- Corrective Actions: Procedures for halting production, re-cleaning, and reassessing products if sanitation fails.

- Training and Awareness: Workers educated not only on how to clean but also why sanitation matters for safety.

By structuring sanitation as a measurable and enforceable CCP, fish processors can ensure that it is consistently maintained at the highest level.

Practical Strategies for the Fishing Industry

To strengthen sanitation practices, seafood processors are increasingly adopting innovative methods, including:

- Hygienic Design: Choosing equipment made from stainless steel with smooth, easy-to-clean surfaces.

- Separation of Areas: Keeping raw fish handling separate from cooked or ready-to-eat areas to avoid cross-contamination.

- Color-Coding Systems: Assigning specific cleaning tools to different zones to reduce mixing of contaminants.

- Automation in Cleaning: Using Clean-in-Place (CIP) systems to standardize sanitation for complex machinery.

These strategies not only improve hygiene but also enhance efficiency by reducing downtime and human error.

Benefits Beyond Regulatory Compliance

While the primary goal of sanitation as a CCP is compliance with HACCP and international regulations, the benefits extend further:

- Stronger Market Access: Meeting sanitation standards helps seafood companies export to strict markets like the EU, US, and Japan.

- Consumer Confidence: Clean and safe products reassure buyers and strengthen brand loyalty.

- Operational Reliability: Well-maintained equipment lasts longer and performs more consistently.

- Crisis Prevention: Effective sanitation reduces the likelihood of costly recalls and public health incidents.

In seafood processing, sanitation is not a background task but a frontline safeguard. By elevating it to the level of a Critical Control Point within HACCP, fish processors acknowledge its power to prevent contamination and protect public health.

From preventing invisible microbial hazards to reducing allergen risks, sanitation plays a vital role in ensuring seafood safety. Facilities that treat sanitation as a CCP are not only compliant with international standards but also better positioned to earn consumer trust, secure global market opportunities, and protect their brand reputation.

At its core, safe fish products begin with clean equipment—a principle that every successful seafood processor upholds.

If youre interested in our Emperor Fillet Skinless, Snapper Fillet Skinless, Crimson Snapper Whole Round, Parrotfish Fillet Skinless, and Grouper Fillet Skinless please do not hesitate to contact us through email and/or whatsapp

.jpg)